- Home

- Machining 304 Vs 316

Machining 304 Vs 316: Which Stainless Steel Provides Superior Performance for Manufacturers?

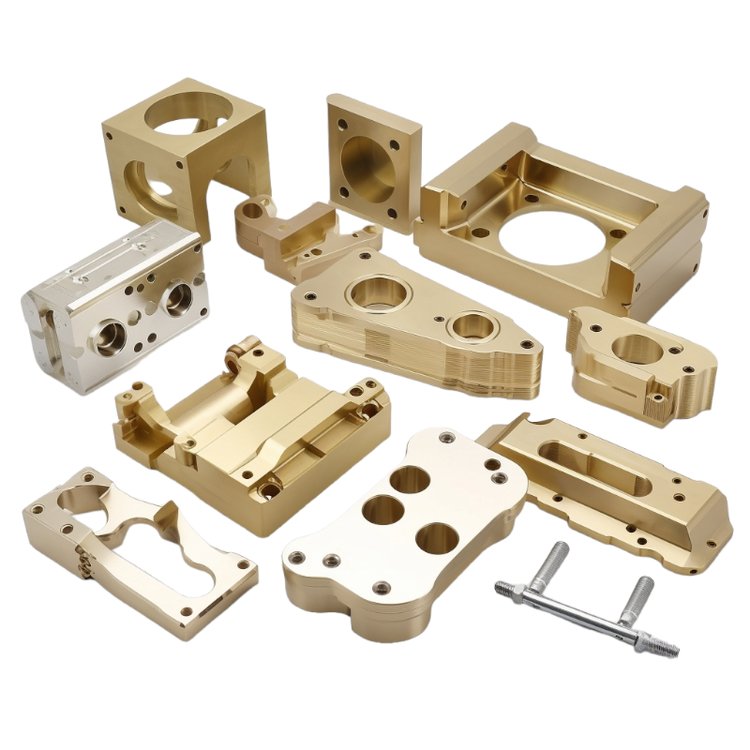

Introducing the finest quality machining solution for stainless steel applications - Dongguan K-Tek Machining Co., Ltd. As a leading manufacturer, supplier, and factory based in China, we specialize in providing excellent machining services for various stainless steel grades, including the highly popular 304 and 316 alloys.

When it comes to machining 304 vs 316 stainless steel, both alloys possess exceptional corrosion resistance, making them ideal for a wide range of industries. However, their compositions and properties differ in certain aspects. At Dongguan K-Tek Machining Co., Ltd., our team of highly skilled engineers and technicians thoroughly understands these differences and is capable of providing top-notch machining services tailored to meet the unique requirements of each grade.

With state-of-the-art machinery and cutting-edge techniques, we ensure precise and efficient machining of both 304 and 316 stainless steel. Our commitment to quality, combined with our extensive experience in the industry, enables us to deliver superior products that satisfy the most demanding customer specifications.

Trust Dongguan K-Tek Machining Co., Ltd. to be your reliable partner for all your stainless steel machining needs. Contact us today to learn more about our comprehensive range of services and how we can optimize your machining processes for enhanced productivity and outstanding results.

K-Tek Machining Co., Ltd.

Company News

Related News

Surface Treatment Services--meet the corrosion resistance, wear resistance

Discover our high-quality Surface Treatment Services, offering exceptional corrosion resistance and wear resistance. Trust in our factory expertise for top-notch results.

Copper processing service--focusing on a variety of small batch production

Discover top-quality copper processing service for small batch production at our factory. We offer efficient and reliable solutions for all your copper processing needs. Contact us now!

5 Axis CNC Machining Services

Offering top-notch {5 Axis CNC Machining Services}, our factory delivers precision and quality. Contact us for innovative solutions to your machining needs.

CNC Milling Services--engaged in the custom processing

Looking for CNC milling services? Look no further! Our factory specializes in custom processing. Get high-quality products with precision and efficiency.

Plastic processing service--rich experience in processing parts

Plastic Processing Service - Unmatched Expertise in Part Manufacturing. As a leading factory, we offer top-notch plastic processing solutions for all your production needs. Contact us now!

Stainless steel processing service

Choose our superior stainless steel processing service factory for precision and quality. We offer a wide range of expert solutions. Contact us today!

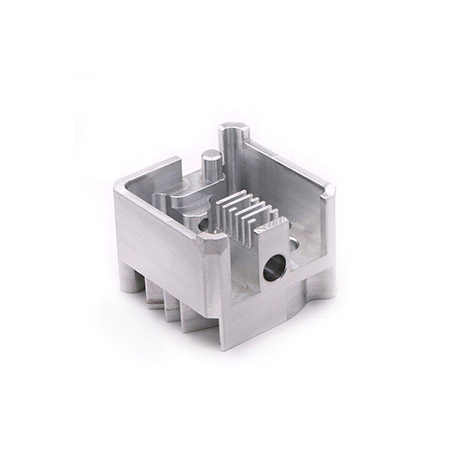

Steel processing service--professional precision machine parts

Welcome to our factory offering professional steel processing services for precision machine parts. Get high-quality products for your business needs.

Machining of aluminum parts--more than 10 years of processing experience

Leading Factory with Over 10 Years of Experience in Aluminum Part Machining. Get High-Quality Products. Request a Quote Now!

K-Tek Overview Brochure

Discover the high-quality offerings of K-Tek, the leading factory specialized in manufacturing and delivering innovative and reliable products. Explore our K-Tek Overview Brochure now!

CNC Turning Services-- engaged in multi-variety and small-batch mechanical parts

Looking for precision CNC turning services for multi-variety and small-batch mechanical parts? Look no further! Our factory specializes in delivering high-quality products.

- Comparing Machining 304 vs 316: Which Stainless Steel is Better for Manufacturers?

- Reviews

- Related Videos

Introducing our revolutionary machining solution for stainless steel: the Machining 304 Vs 316 machine. In the field of metal fabrication and engineering, machining stainless steel has always been a challenging task. With our cutting-edge technology, we have developed a machine that is specifically designed to handle the unique properties of both 304 and 316 grades of stainless steel, ensuring superior results and optimum efficiency. 304 and 316 stainless steel are two of the most commonly used stainless steel alloys due to their excellent corrosion resistance, strength, and versatility. However, machining these alloys can be tricky due to their varying characteristics. Our Machining 304 Vs 316 machine is built to tackle these challenges head-on, providing precision machining and exceptional surface finishes for both 304 and 316 stainless steel. Equipped with state-of-the-art tools and advanced software, our machine offers unmatched accuracy and efficiency, reducing production time and costs. The machine's intelligent programming allows for seamless customization, ensuring precise machining for specific applications and requirements. Whether you are fabricating components for the medical, aerospace, or automotive industry, our Machining 304 Vs 316 machine is the perfect solution for all your stainless steel machining needs. Not only does our machine deliver exceptional performance, but it also prioritizes safety and operator comfort. With its user-friendly interface and advanced safety features, operators can confidently operate the machine, minimizing the risk of accidents and maximizing productivity. In summary, our Machining 304 Vs 316 machine revolutionizes the stainless steel machining industry. Its ability to handle the unique properties of 304 and 316 stainless steel ensures superior results, precision, and efficiency. Experience the future of stainless steel machining with our cutting-edge technology.

When comparing machining 304 versus 316 stainless steel, the latter takes the lead. With its higher molybdenum content, 316 stainless steel offers improved corrosion resistance compared to 304. As a result, it proves more suitable for applications involving exposure to harsh environments or chemicals. In terms of machining, 316 stainless steel may present some challenges due to its higher strength but can still be effectively machined with the right tools and techniques. Careful selection of cutting speeds, feeds, and coolant is crucial to achieve optimal results. Its inherent strength, toughness, and resistance to pitting make it an excellent choice for machining projects requiring durability and longevity. Overall, if you are seeking a stainless steel with superior corrosion resistance without compromising machining capabilities, 316 stainless steel is the way to go.

When it comes to machining stainless steel, specifically 304 and 316, there are some key differences to consider. One notable distinction is the higher corrosion resistance of 316 stainless steel, making it an ideal choice for marine and coastal applications. Machining 316 stainless steel requires special attention due to its slightly higher hardness compared to 304. However, both materials are machinable with the right tools and techniques. 304 stainless steel offers good machining properties and is widely used in various industries. Ultimately, the choice between 304 and 316 for machining depends on the specific requirements of your project. Ensure to consult with experts to select the most suitable stainless steel option for optimal results.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours