Top Tips for Effective Aluminium Milling

By:Admin

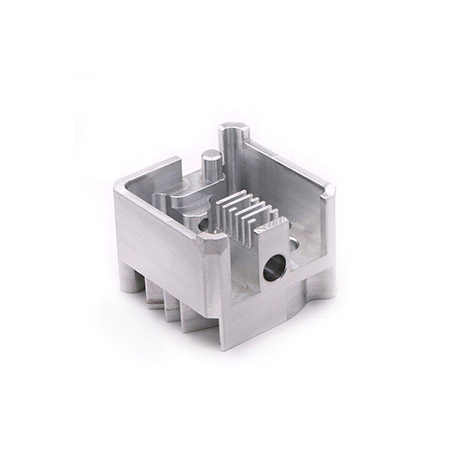

Aluminium has been a popular material in various industries due to its lightweight and durable properties. And with the advancements in technology, aluminium milling has become an essential process in crafting high-quality aluminium products. This is where [Company Name] comes into play, offering innovative solutions in aluminium milling that are set to revolutionize the industry.

[Company Name] is a leading provider of aluminium milling services, catering to a wide range of industries including aerospace, automotive, marine, and more. With state-of-the-art facilities and a team of expert engineers, [Company Name] has been at the forefront of delivering precision-machined aluminium components that meet the highest standards of quality and performance.

The company's commitment to excellence and continuous improvement has made them a trusted partner for businesses looking to leverage the benefits of aluminium milling. From prototyping to large-scale production, [Company Name] offers a comprehensive range of milling services that are tailored to their clients' specific needs. Whether it's CNC milling, 5-axis milling, or custom machining, the company has the capabilities to handle the most complex projects with precision and efficiency.

One of the key differentiators of [Company Name] is their emphasis on innovation and technology. They have invested heavily in cutting-edge milling equipment and software, allowing them to achieve unparalleled accuracy and speed in their milling processes. This has enabled them to take on challenging projects that require tight tolerances and intricate designs, setting them apart as a leader in the industry.

In addition to their technical capabilities, [Company Name] is also dedicated to sustainability and environmental responsibility. They have implemented eco-friendly practices in their operations, such as recycling aluminium scraps and minimizing waste generation. This commitment to sustainability not only benefits the environment but also resonates with their clients who are looking to partner with socially responsible suppliers.

Moreover, [Company Name] has a strong focus on customer satisfaction, aiming to build long-term partnerships with their clients. They work closely with each client to understand their requirements and provide tailored solutions that meet their needs. Whether it's rapid prototyping for a new product or high-volume production for an established line, the company is dedicated to delivering results that exceed expectations.

As the demand for aluminium products continues to grow across various industries, the need for reliable and efficient milling services has never been greater. [Company Name] is well-positioned to meet this demand with their expertise, technology, and commitment to excellence. They are poised to play a pivotal role in shaping the future of aluminium milling, driving innovation and pushing the boundaries of what's possible in the industry.

In conclusion, [Company Name] is a trailblazer in the field of aluminium milling, offering a unique combination of expertise, technology, and customer-centric approach. With a steadfast commitment to quality, sustainability, and innovation, they are set to revolutionize the industry and establish themselves as the go-to partner for businesses seeking top-notch aluminium milling services. As they continue to expand their capabilities and reach, [Company Name] is poised to lead the way towards a brighter and more efficient future for aluminium milling.

Company News & Blog

The Benefits of Custom Metal Forging in Manufacturing Processes

Custom Metal Forging Company Partners with Industry Leader to Enhance Product OfferingsCustom Metal Forging, a leading provider of precision metal components, has announced a new partnership with a renowned industry leader to further expand its product offerings and enhance its capabilities. With a commitment to excellence and innovation, Custom Metal Forging has built a reputation for delivering high-quality, made-to-order metal components for a wide range of industries. This partnership represents a significant step forward for the company and reinforces its dedication to meeting the diverse needs of its customers.The partnership will allow Custom Metal Forging to leverage the expertise and resources of the industry leader to offer an even wider range of custom metal forging solutions. By combining forces, the two companies aim to enhance their respective capabilities and provide customers with a comprehensive suite of products and services. This collaboration is expected to result in greater efficiency, higher quality products, and increased flexibility in meeting the unique requirements of each customer.Custom Metal Forging specializes in producing complex and intricately shaped metal components for a variety of applications, including automotive, aerospace, defense, and industrial machinery. With state-of-the-art facilities and a team of highly skilled engineers and technicians, the company has the capacity to deliver custom-forged parts that meet the most stringent industry standards. By joining forces with the industry leader, Custom Metal Forging is poised to take its capabilities to the next level and solidify its position as a trusted partner for precision metal components.The partnership is a testament to Custom Metal Forging's unwavering commitment to providing innovative solutions and exceeding customer expectations. By aligning with a company that shares its dedication to quality and excellence, Custom Metal Forging is paving the way for further growth and success in the highly competitive metal forging industry. The company's ability to adapt to the evolving needs of its customers and the market at large has been a key driver of its continued success, and this partnership is a reflection of its ongoing efforts to stay at the forefront of industry trends and advancements.Custom Metal Forging's collaboration with the industry leader is expected to result in a synergistic relationship that will benefit both companies and their customers. By combining their respective strengths and capabilities, the two companies will be better positioned to address the increasing demand for high-quality, custom-forged metal components. This strategic partnership underscores Custom Metal Forging's proactive approach to staying ahead of the curve and continuously improving its offerings to better serve its customers.As the industry landscape continues to evolve, Custom Metal Forging remains dedicated to enhancing its capabilities and expanding its product offerings to meet the ever-changing needs of its customers. The company's partnership with the industry leader is a significant milestone in its ongoing pursuit of excellence and innovation. Customers can expect to benefit from the enhanced solutions and services that will result from this collaboration, further solidifying Custom Metal Forging's position as a leading provider of custom metal forging solutions.In conclusion, Custom Metal Forging's partnership with the industry leader represents an exciting new chapter for the company and its customers. By joining forces, the two companies are poised to deliver enhanced capabilities and a broader range of products and services. This collaborative effort underscores Custom Metal Forging's commitment to continuous improvement and its dedication to providing unparalleled quality and innovation in the custom metal forging industry. As the partnership takes shape, customers can look forward to reaping the benefits of this dynamic collaboration through an even greater array of precision metal components.

Achieving High Precision Machining Tolerances: What You Need to Know

High Precision Machining Tolerances: Setting the Standard for Precision EngineeringWhen it comes to precision engineering, nothing is more important than achieving high precision machining tolerances. These tolerances are crucial for ensuring the accuracy and quality of machined components, and they require cutting-edge technology and expertise to achieve. That's where [Company] comes in. [Company] is a leading provider of high precision machining services, specializing in meeting the most exacting tolerances for a wide range of industries, including aerospace, automotive, medical, and more. With a commitment to quality and precision, [Company] has become a trusted partner for organizations seeking to achieve the highest levels of accuracy in their machined components.One of the key factors that sets [Company] apart from its competitors is its state-of-the-art machining capabilities. The company utilizes the latest CNC machining technology and employs a team of highly skilled machinists to ensure that the most demanding tolerances can be met. This level of precision is critical for applications where even the smallest deviation can result in performance issues or failure.In addition to its advanced equipment and expertise, [Company] also places a strong emphasis on quality control. The company's quality management system is certified to ISO 9001 standards, demonstrating its commitment to delivering exceptional quality and reliability in every machined component. This dedication to quality has earned [Company] a solid reputation as a reliable partner for organizations with stringent quality requirements.One of the industries that [Company] serves is the aerospace industry, where precision and reliability are absolutely critical. Machined components for aerospace applications must adhere to extremely tight tolerances to ensure that they can withstand the rigors of flight and perform flawlessly in demanding environments. With its advanced machining capabilities and commitment to quality, [Company] has become a trusted supplier for aerospace manufacturers, delivering precision-engineered components that meet or exceed the industry's exacting standards.Another industry where high precision machining tolerances are essential is medical devices. Components for medical devices must meet very strict specifications to ensure their safety and efficacy. [Company] has the expertise and technology to produce complex, high-precision components for medical devices, helping its customers bring life-saving and life-improving technologies to market.In the automotive industry, [Company] plays a critical role in producing precision components for a wide range of applications, from performance racing to safety-critical systems. The company's ability to meet tight tolerances and deliver consistently high-quality products has made it a preferred supplier for automotive manufacturers and suppliers.Overall, [Company] is dedicated to pushing the boundaries of precision engineering. By investing in the latest technology, employing a highly skilled workforce, and maintaining a relentless focus on quality, the company has positioned itself as a leader in the high precision machining industry. Its ability to meet the most demanding tolerances has made it a trusted partner for organizations across a wide range of industries, and its commitment to excellence ensures that it will continue to set the standard for precision engineering in the years to come.

High-quality Black Anodizing Services for Enhanced Durability and Aesthetic Appeal

Black Anodizing Services, a leading company in the surface finishing industry, has announced the expansion of its services to cater to the growing demand for black anodizing in the manufacturing sector. With a commitment to providing high-quality and innovative surface finishing solutions, Black Anodizing Services is well-positioned to meet the needs of its clients in various industries.The company, headquartered in the heart of the manufacturing hub, has gained a reputation for excellence in anodizing and other surface finishing processes. With state-of-the-art facilities and a team of skilled professionals, Black Anodizing Services offers a wide range of surface finishing services, including black anodizing, which is a specialized electrochemical process that enhances the durability and aesthetic appeal of metal components.Black anodizing is a process that creates a sleek, black finish on metal parts, providing resistance to corrosion, wear, and abrasion. This makes it an ideal choice for a wide range of applications, including automotive, aerospace, defense, and consumer electronics. With the expansion of its black anodizing services, Black Anodizing Services aims to meet the growing demand for high-quality black anodized parts in these and other industries.The company's black anodizing process involves immersing the metal parts in an electrolyte solution and passing an electric current through it. This creates an oxide layer on the surface of the metal, which can then be dyed black to achieve the desired finish. The result is a durable and visually appealing black finish that meets the highest standards of quality and performance.In addition to black anodizing, Black Anodizing Services offers a range of other surface finishing processes, including type II and type III anodizing, chemical film conversion coating, and powder coating. This allows the company to provide comprehensive surface finishing solutions to its clients, meeting all their needs under one roof.With a focus on quality, precision, and customer satisfaction, Black Anodizing Services has built a strong reputation as a reliable partner for manufacturers seeking high-quality surface finishing solutions. The company's commitment to continuous improvement and investment in the latest technologies ensures that it stays at the forefront of the industry, meeting the evolving needs of its clients with cutting-edge solutions."We are excited to announce the expansion of our black anodizing services to meet the growing demand for this specialized finish in the manufacturing industry," said the spokesperson for Black Anodizing Services. "With our state-of-the-art facilities and experienced team, we are well-equipped to deliver high-quality black anodized parts that meet the strictest standards of quality and performance. We look forward to serving our clients with the same excellence and dedication that have made us a trusted name in the surface finishing industry."As the manufacturing industry continues to evolve and demand for high-quality surface finishing solutions grows, Black Anodizing Services is poised to play a key role in meeting these needs. With its expanded black anodizing services and a commitment to excellence, the company is well-positioned to be a preferred partner for manufacturers seeking top-quality surface finishing solutions.For more information about Black Anodizing Services and its comprehensive range of surface finishing solutions, visit their website or contact them directly to discuss specific requirements and learn how they can help with your surface finishing needs.

Aluminum CNC Machining Services: Custom Solutions for Your Needs

Custom Aluminum CNC Machining - Leading the Way in Precision EngineeringIn today's fast-paced and rapidly evolving manufacturing industry, precision engineering and custom CNC machining play a crucial role in the production of high-quality and durable components. One company that has been leading the way in this field is {}. With their expertise in aluminum CNC machining, they have been able to cater to the diverse needs of their clients and deliver exceptional results.As a leading provider of custom aluminum CNC machining services, {} brings a wealth of experience and knowledge to the table. Their state-of-the-art facility is equipped with the latest CNC machines, allowing them to produce complex and intricate aluminum components with utmost precision. Whether it's prototypes, small batch productions, or large-scale projects, their team of skilled engineers and machinists can handle it all with ease.One of the key advantages of custom aluminum CNC machining is its versatility and ability to produce parts with tight tolerances. This is especially important in industries such as aerospace, automotive, and electronics, where precision and accuracy are of utmost importance. With {}'s expertise in CNC machining, they are able to ensure that each component meets the exact specifications and requirements of their clients.In addition to precision, custom aluminum CNC machining also offers a range of other benefits, including cost-effectiveness, fast production times, and the ability to work with a variety of aluminum alloys. {} understands the unique properties of different aluminum alloys and can recommend the most suitable material for each project, ensuring the optimal performance and longevity of the end product.Another factor that sets {} apart from their competitors is their commitment to quality and customer satisfaction. They work closely with their clients at every stage of the machining process, from design and prototyping to final production, to ensure that the end result meets their expectations. With a focus on continuous improvement and investment in the latest technologies, {} is dedicated to providing the best possible solutions for their clients' CNC machining needs.Moreover, {}'s commitment to sustainability and environmental responsibility sets them apart in the industry. They have implemented strict measures to reduce waste, energy consumption, and emissions in their production processes, while also investing in eco-friendly materials and practices. This commitment to sustainability not only benefits the environment but also reflects positively on their clients' corporate social responsibility efforts.With a track record of successful projects and satisfied clients, {} has established themselves as a trusted partner for custom aluminum CNC machining. Their expertise, dedication to quality, and commitment to innovation make them the go-to choice for businesses looking for reliable and high-quality machining solutions.In conclusion, custom aluminum CNC machining plays a crucial role in the manufacturing industry, and {} has set a high standard in this field. Their precision engineering capabilities, state-of-the-art facility, commitment to quality, and focus on sustainability make them a leader in the industry. As they continue to push the boundaries of innovation and excellence, {} is well-positioned to meet the evolving needs of their clients and contribute to the advancement of the manufacturing sector.

High Precision CNC Turning Lathe for manufacturing applications

In today's rapidly evolving manufacturing industry, the demand for high-quality precision components is at an all-time high. Companies across the globe are continually seeking innovative solutions to meet this demand, and one company that is leading the way in this regard is {}. Specializing in the manufacturing of precision components, {} has recently announced the acquisition of the latest CNC turning lathe technology, further solidifying their position as a leader in the industry.The CNC turning lathe is a cutting-edge piece of machinery that is used to manufacture precisely engineered components with unparalleled accuracy and efficiency. By utilizing computer programming to control the cutting tools, the CNC turning lathe is capable of producing complex components with tight tolerances, making it an essential tool for industries such as aerospace, automotive, medical, and more. With the addition of this state-of-the-art technology, {} is well-equipped to meet the evolving needs of their diverse client base.{} has a long-standing reputation for excellence in the manufacturing industry, with a commitment to delivering top-quality products to their customers. The company's extensive experience and expertise in precision machining make them the go-to choice for clients seeking reliable and innovative manufacturing solutions. With a focus on continuous improvement and investment in cutting-edge technology, {} consistently exceeds customer expectations and sets the standard for excellence in the industry.The acquisition of the new CNC turning lathe represents a significant milestone for {}. With this advanced machinery, the company is now capable of producing even more complex and intricate components with higher precision and faster turnaround times. Additionally, the CNC turning lathe will enhance {}'s ability to innovate and adapt to the ever-changing demands of the market, ensuring that they remain at the forefront of the industry.In a statement regarding the acquisition, {}'s CEO expressed excitement about the potential of the new CNC turning lathe, stating, "We are thrilled to add this cutting-edge technology to our arsenal of manufacturing capabilities. The CNC turning lathe will allow us to expand our production capacity and deliver even more precise and high-quality components to our clients. This investment reaffirms our commitment to continuous improvement and positions us for continued success in the industry."The CNC turning lathe is just the latest addition to a comprehensive suite of advanced manufacturing equipment at {}. With a broad range of capabilities, the company is able to accommodate a multitude of client needs, from prototyping and small-batch production to large-scale manufacturing. The addition of the CNC turning lathe further enhances {}'s ability to serve clients across diverse industries, solidifying their reputation as a trusted and dependable manufacturing partner.As the manufacturing industry continues to evolve, {} remains dedicated to staying ahead of the curve and delivering the highest quality products to their customers. With the acquisition of the new CNC turning lathe, the company is well-positioned to take on new challenges and opportunities, further solidifying their standing as an industry leader. In conclusion, the addition of the CNC turning lathe is a significant development for {}, providing the company with the tools and capabilities necessary to meet the increasing demands of the manufacturing industry. With a strong focus on precision, quality, and technological advancement, {} is well-equipped to deliver exceptional results for their clients and maintain their position as a leader in the industry.

Online Ordering for CNC Products: A Complete Guide

CNC Online Order Enhances Customer Ordering Experience (Remove Brand Name)In today’s fast-paced and highly competitive business world, companies are constantly looking for innovative ways to improve their operations and enhance the overall customer experience. With the rise of e-commerce and online ordering, many companies are turning to digital platforms to streamline their ordering processes and provide customers with a more convenient and efficient way to purchase their products and services.One company that is leading the way in this digital transformation is {}. With over [X] years of experience in the industry, {} has built a reputation for manufacturing high-quality CNC machinery and providing exceptional customer service. In an effort to further improve their operations and better serve their customers, {} has recently launched CNC Online Order, a new digital platform that allows customers to place orders for CNC machinery and parts directly through their website.“We understand the importance of providing our customers with a seamless and convenient ordering process,” said [Spokesperson’s Name], Vice President of Sales at {}. “With CNC Online Order, our customers can now easily browse our product catalog, select the items they need, and place their orders with just a few clicks. This new platform is designed to enhance the overall ordering experience and make it easier for our customers to do business with us.”The CNC Online Order platform offers a user-friendly interface that allows customers to quickly search for specific products, view detailed product information, and place their orders with ease. Customers can also access real-time inventory availability and pricing information, ensuring that they have the most up-to-date information when making their purchasing decisions.One of the key benefits of CNC Online Order is its ability to streamline the ordering process and reduce the time it takes for customers to receive their orders. By eliminating the need for manual order entry and processing, {} can now fulfill orders more efficiently and expedite the delivery of products to their customers.Additionally, CNC Online Order provides customers with greater transparency and visibility into the status of their orders. Through the platform, customers can track the progress of their orders, receive shipment notifications, and access historical order information, giving them greater peace of mind and confidence in their purchasing experience.“We are committed to leveraging technology to improve every aspect of our business,” said [Spokesperson’s Name]. “CNC Online Order is just one example of how we are embracing digital innovation to better serve our customers. Our goal is to continuously enhance the customer experience and provide our customers with the tools and resources they need to succeed in their operations.”The launch of CNC Online Order reflects {}’s dedication to meeting the evolving needs of their customers and adapting to the digital transformation of the industry. By providing a modern and efficient online ordering platform, {} is empowering their customers to make informed purchasing decisions, save time, and streamline their operations.As {} continues to invest in digital initiatives and customer-centric solutions, the company remains focused on delivering superior value and service to their customers. With CNC Online Order, {} is setting a new standard for the ordering experience in the CNC machinery industry, and cementing their position as a leader in innovation and customer satisfaction.As the digital transformation of the manufacturing industry continues to accelerate, companies like {} are at the forefront of driving change and shaping the future of the industry. With CNC Online Order, {} is demonstrating their commitment to excellence and their dedication to providing customers with the best possible experience when purchasing CNC machinery and parts.To learn more about CNC Online Order and explore the wide range of CNC machinery and parts offered by {}, visit their website at [website URL].

High-quality Anodized Aluminum Parts for Various Applications

Anodized Aluminum Parts Market, North America, Europe, Asia-Pacific, South America, Middle East and AfricaThe global Anodized Aluminum Parts market size was XX million US$ and is expected to reach XX million US$ by the end of 2026, with a CAGR of XX% during 2021-2026.Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.The global Anodized Aluminum Parts market is expecting significant growth driven by factors such as increasing demand from end-use industries like automotive, aerospace, and construction, which require anodized aluminum parts for various manufacturing and assembly processes.In the automotive industry, anodized aluminum parts are used in components like body panels, trim, wheels, and other critical parts, due to their lightweight and corrosion-resistant properties. This market is further driven by the increasing production and sales of automobiles worldwide.In the aerospace industry, anodized aluminum parts are used in aircraft construction and components because of their high strength-to-weight ratio, corrosion resistance, and the ability to withstand harsh environmental conditions.In the construction industry, anodized aluminum parts are used in architectural applications such as window frames, roofing, cladding, and curtain walls due to their aesthetic appeal, durability, and low maintenance requirements.The Asia-Pacific region is expected to witness significant growth in the anodized aluminum parts market, driven by the rapid industrialization and urbanization in countries such as China, India, and Japan. The increasing construction and automotive sectors in the region are contributing to the demand for anodized aluminum parts.North America and Europe are also prominent regions in the anodized aluminum parts market due to the presence of major automotive and aerospace manufacturers and the increasing demand for lightweight and durable materials in these industries.[Company Name] is a leading manufacturer and supplier of anodized aluminum parts, offering a wide range of products to cater to the specific needs of various industries. With state-of-the-art facilities and a team of experienced professionals, [Company Name] is committed to delivering high-quality anodized aluminum parts that meet industry standards and customer specifications.The company's anodized aluminum parts are known for their excellent corrosion resistance, enhanced durability, and aesthetically appealing finishes, making them suitable for diverse applications in automotive, aerospace, construction, and other industries. Utilizing advanced anodizing techniques, [Company Name] ensures that its products meet the highest quality standards and exceed customer expectations.In addition to its extensive product range, [Company Name] also offers custom solutions and value-added services to meet specific customer requirements. With a focus on innovation and continuous improvement, the company remains at the forefront of the anodized aluminum parts market, providing reliable and efficient solutions to its global clientele.As the demand for anodized aluminum parts continues to grow across various industries, [Company Name] is poised to capitalize on the opportunities and further strengthen its position as a leading player in the global market. With a strong commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of its customers and contribute to the growth of the anodized aluminum parts market.

High-Quality Black Anodised Aluminium: A Durable and Stylish Option

Black Anodised Aluminium is a material that has quickly gained popularity in various industries due to its unique properties and versatile applications. One of the leading manufacturers of Black Anodised Aluminium is {brand name removed}, a company that has been at the forefront of producing high-quality aluminium products for the past decade.{brand name removed} was established in 2010 with the goal of providing innovative and reliable aluminium solutions to industries such as automotive, aerospace, construction, and electronics. The company has since grown to become a trusted name in the industry, known for its commitment to excellence and customer satisfaction.The black anodising process is a method of creating a durable and long-lasting surface on aluminium, making it resistant to corrosion and wear. This makes black anodised aluminium an ideal choice for applications that require a high level of durability and aesthetic appeal. {brand name removed} has invested heavily in state-of-the-art anodising facilities, allowing them to produce black anodised aluminium with exceptional quality and consistency. The company's team of skilled technicians and engineers work tirelessly to ensure that each batch of black anodised aluminium meets the highest standards and adheres to strict quality control measures.One of the key advantages of black anodised aluminium is its aesthetic appeal. The process of anodising creates a sleek and uniform black finish that not only looks visually appealing but also enhances the overall durability of the aluminium. This makes it a popular choice for industries such as automotive and electronics, where the appearance of the final product is just as important as its performance.In addition to its visual appeal, black anodised aluminium also offers superior corrosion resistance, making it suitable for outdoor and marine applications. This has led to an increased demand for black anodised aluminium in industries that require materials capable of withstanding harsh environmental conditions.Furthermore, black anodised aluminium is highly resistant to abrasion and wear, making it an ideal choice for applications that involve frequent handling or exposure to friction. This has made it a preferred material for products such as hand tools, consumer electronics, and architectural components.{brand name removed} has continually expanded its product range to offer a wide variety of black anodised aluminium products, including sheets, coils, extrusions, and custom-made components. This versatility allows the company to cater to the unique needs of each industry and offer tailored solutions to its clients.The company's commitment to sustainability is another key aspect of its business operations. {brand name removed} has implemented environmentally-friendly practices in its anodising processes, ensuring that its black anodised aluminium products are produced with minimal impact on the environment. This has earned {brand name removed} recognition as a responsible and eco-conscious supplier in the aluminium industry.Looking ahead, {brand name removed} aims to continue its innovative approach to black anodised aluminium production, exploring new technologies and techniques to further enhance the performance and versatility of its products. The company is also focused on expanding its market reach and forging partnerships with businesses that value high-quality aluminium solutions.With its dedication to excellence, commitment to sustainability, and continuous drive for innovation, {brand name removed} is poised to remain a leading player in the black anodised aluminium industry. As the demand for durable, visually appealing aluminium products continues to grow, {brand name removed} stands ready to meet the needs of industries around the world and provide them with reliable black anodised aluminium solutions.

High-Quality CNC Machined Plastic Parts: A Comprehensive Guide

CNC Machined Plastic Parts: A Precision Manufacturing SolutionIn the ever-evolving world of manufacturing, precision and accuracy are key components in producing high-quality products. This is where CNC machined plastic parts come into play. With the advanced technology and expertise of our company, we are proud to offer top-notch CNC machined plastic parts that meet the needs of various industries.Our state-of-the-art manufacturing facility is equipped with the latest CNC machining technology, including high-speed machining centers and multi-axis CNC machines. This allows us to produce complex and intricate plastic parts with tight tolerances and superior surface finishes. Whether it's a prototype or a high-volume production run, our CNC machining capabilities can meet the most demanding requirements.The benefits of CNC machined plastic parts are vast. They offer high precision and repeatability, ensuring that each part is identical to the next. This consistency is crucial in industries such as aerospace, automotive, medical, and consumer electronics, where quality and reliability are non-negotiable. Additionally, CNC machined plastic parts can be manufactured with a wide range of thermoplastics and thermoset materials, providing flexibility in design and performance.Our company takes great pride in our ability to deliver CNC machined plastic parts that exceed our customers' expectations. From initial concept to final production, we work closely with our clients to understand their specific needs and requirements. Our team of experienced engineers and machinists ensures that every aspect of the manufacturing process is meticulously executed, resulting in high-quality parts that are ready for immediate use.Furthermore, our commitment to quality extends beyond the manufacturing process. We adhere to strict quality control measures and inspection protocols to guarantee that each CNC machined plastic part meets the highest standards. This dedication to quality has earned us a reputation for reliability and consistency in the industry.Beyond the technical capabilities of our manufacturing facility, we understand the importance of timeliness and cost-efficiency. Our streamlined production processes and efficient use of materials allow us to deliver CNC machined plastic parts in a timely manner without compromising on quality. We also offer competitive pricing without sacrificing the precision and performance of our products.With our extensive experience in CNC machining, we have successfully produced a wide range of plastic parts, including but not limited to gears, pulleys, housings, enclosures, and fittings. Our expertise extends to custom and specialty projects, where we can assist in the design and development of unique plastic parts tailored to our customers' specific needs.In conclusion, the demand for precision and accuracy in manufacturing continues to grow, and CNC machined plastic parts have become a vital solution for industries worldwide. With our advanced technology, skilled workforce, and unwavering commitment to quality, we are proud to be a leading provider of CNC machined plastic parts. Our dedication to excellence and customer satisfaction sets us apart in the industry, and we look forward to continuing to meet the needs of our clients with our innovative manufacturing solutions.For more information about our CNC machined plastic parts capability, please visit [company website] or contact us directly to discuss your specific manufacturing needs.Contact Information:[Company Name][Company Address][Phone Number][Email Address][Website]

How to Achieve Precision Machining for Parts

Precision machining is an integral part of the manufacturing process for a wide range of industries, from automotive to aerospace, and everything in between. The demand for high-quality precision parts has never been greater, as manufacturers strive to produce more efficient and reliable products. In this competitive landscape, companies are constantly looking for ways to improve their machining capabilities in order to meet the growing demand for precision parts.One company that has been at the forefront of precision machining is {Company Name}. With decades of experience in the industry, {Company Name} has established itself as a trusted provider of precision parts for a variety of applications. Its state-of-the-art facilities and skilled workforce have enabled the company to consistently deliver high-quality precision parts to its customers, meeting their exact specifications and requirements.Recently, {Company Name} announced an expansion of its precision machining capabilities, further solidifying its position as a leader in the industry. The company has made significant investments in new equipment and technology, allowing it to produce even more complex and intricate parts with the utmost precision. This expansion will not only enhance {Company Name}'s ability to meet the increasing demand for precision parts, but also allow it to take on new and challenging projects.The new equipment includes advanced CNC machining centers, high-speed milling machines, and precision grinding equipment, all of which are designed to meet the exacting standards of the industry. These machines are capable of working with a wide range of materials, from aluminum and stainless steel to exotic alloys and plastics, ensuring that {Company Name} can meet the diverse needs of its customers.In addition to the new equipment, {Company Name} has also invested in the latest software and programming tools, enabling its engineers and technicians to create highly complex and precise part designs. This advanced technology allows the company to optimize its manufacturing processes, reducing lead times and improving overall efficiency. As a result, {Company Name} will be able to offer its customers even greater flexibility and responsiveness, ensuring that their needs are always met in a timely manner.{Company Name}'s commitment to quality and precision is further exemplified by its rigorous quality control processes. Every part that leaves the company's facilities undergoes thorough inspection and testing to ensure that it meets the highest standards of accuracy and performance. This dedication to quality has earned {Company Name} a reputation for excellence in the industry, and has made it the go-to choice for many customers seeking precision parts.With its expanded capabilities, {Company Name} is poised to continue its success in the precision machining industry. By investing in the latest technology and equipment, the company has positioned itself to meet the evolving needs of its customers, while maintaining its unwavering commitment to quality and precision. As the demand for high-quality precision parts continues to grow, {Company Name} is well-equipped to lead the way, providing its customers with the innovative solutions they need to succeed in their respective industries.