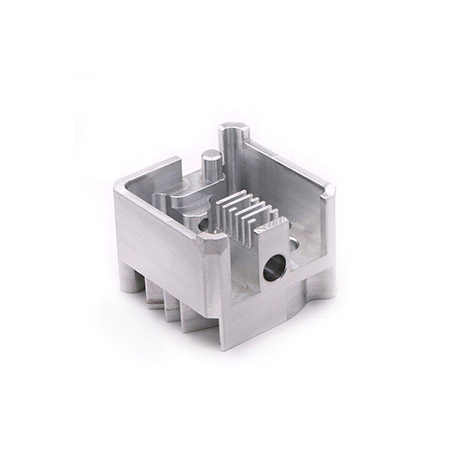

High-Quality Custom CNC Machining Services for Precision Parts

By:Admin

In the ever-evolving world of manufacturing, precision and efficiency are key. This is where custom CNC machining comes into play, providing companies with the capability to produce highly detailed and accurate parts for a wide range of industries. One leading manufacturing company, {Company Name}, is at the forefront of this technology, offering a comprehensive range of custom CNC machining services to meet the diverse needs of its clients.

Established in {year}, {Company Name} has built a strong reputation as a top-tier manufacturing company, specializing in custom CNC machining, CNC turning, and CNC milling. With state-of-the-art facilities and a team of skilled professionals, the company is able to deliver high-quality parts and components to clients across various industries, including aerospace, automotive, medical, and more.

One of the key aspects of {Company Name}'s custom CNC machining services is its ability to work with a wide range of materials. From aluminum and stainless steel to exotic alloys and plastics, the company has the expertise and machinery to handle even the most challenging materials with precision and accuracy. This capability allows {Company Name} to cater to the unique needs of each client, offering custom solutions that meet their specific material requirements.

Furthermore, {Company Name} understands that time is of the essence in manufacturing, which is why it has invested heavily in cutting-edge CNC machines and software to optimize its production processes. This not only ensures fast turnaround times but also guarantees the highest level of quality and consistency in every part produced. By leveraging advanced CNC technology, the company is able to deliver precision parts with tight tolerances, intricate geometries, and complex features, meeting the exact specifications of its clients.

{Company Name} prides itself on its ability to provide personalized and customer-centric services. From the initial consultation to the delivery of the finished parts, the company works closely with its clients to understand their unique requirements and provide tailored solutions that exceed their expectations. Whether it's a low-volume prototype or a high-volume production run, {Company Name} is committed to delivering the highest level of service and quality, ensuring customer satisfaction every step of the way.

In addition to its expertise in custom CNC machining, {Company Name} also offers value-added services such as assembly, finishing, and quality inspections to provide its clients with a complete manufacturing solution. This comprehensive approach allows the company to streamline the production process and deliver fully finished parts, ready for immediate integration into the final product.

As the manufacturing industry continues to evolve, {Company Name} remains at the forefront of innovation, constantly pushing the boundaries of custom CNC machining to meet the evolving needs of its clients. By combining advanced technology, skilled craftsmanship, and personalized service, the company has established itself as a trusted partner for companies looking to bring their innovative designs to life.

In conclusion, {Company Name} is a leading manufacturing company that offers a comprehensive range of custom CNC machining services, catering to the diverse needs of its clients in various industries. With its state-of-the-art facilities, advanced CNC technology, and commitment to customer satisfaction, {Company Name} is well-equipped to deliver high-quality, precision parts that meet the exact specifications of its clients. As the manufacturing landscape continues to evolve, {Company Name} remains dedicated to pushing the boundaries of custom CNC machining and delivering innovative solutions to its clients.

Company News & Blog

High-Quality Custom Machined Parts for Manufacturing Needs

Custom Machined Parts, A Leader in Precision EngineeringCustom Machined Parts is a leading manufacturer of high-quality precision engineered parts for a wide range of industries. With over 20 years of experience in the custom machining industry, they have built a solid reputation for delivering top-notch products and services to their clients.Specializing in the production of custom machined parts, the company utilizes state-of-the-art equipment and advanced manufacturing processes to ensure the consistent quality and precision of their products. Their team of highly skilled engineers and machinists are dedicated to meeting and exceeding the unique requirements and specifications of their clients.The company’s commitment to customer satisfaction and quality has enabled them to establish long-term partnerships with a diverse clientele, including businesses in the aerospace, automotive, medical, and defense industries. Their extensive experience and expertise in machining a wide variety of materials, including aluminum, steel, and plastics, have made them a trusted partner for companies seeking high-quality custom machined parts.Custom Machined Parts takes pride in their ability to deliver complex and intricate parts that meet the strictest tolerances and specifications. Whether it’s a single prototype or a high-volume production run, the company has the capabilities to meet the demands of their clients and deliver exceptional results.In addition to their custom machining services, the company also offers a range of value-added services, including design assistance, material selection, and finishing options such as anodizing, plating, and painting. This comprehensive approach to customer service ensures that clients receive a complete solution for their custom machined parts needs.With a focus on continuous improvement and innovation, Custom Machined Parts is dedicated to staying ahead of industry trends and technological advancements. By investing in the latest machining technology and training their team on the latest techniques, the company remains at the forefront of the custom machining industry.Furthermore, the company places a strong emphasis on quality control and assurance throughout the production process. From initial design to final inspection, every step is carefully monitored to ensure that all products meet the highest standards and specifications.In response to the growing demand for custom machined parts, the company has recently expanded its manufacturing facilities to increase production capacity and accommodate the needs of their clients. This expansion reflects the company’s commitment to growth and their dedication to providing exceptional products and services to their customers.With their unwavering dedication to quality, precision, and customer satisfaction, Custom Machined Parts has cemented its position as a leader in the custom machining industry. As they continue to grow and expand their capabilities, the company remains focused on delivering innovative solutions and exceeding the expectations of their clients.For businesses in need of custom machined parts, Custom Machined Parts offers a reliable and trusted partner with the expertise and capabilities to deliver exceptional results. With their commitment to quality, precision, and customer satisfaction, the company is well-equipped to meet the unique needs of a diverse range of industries.In conclusion, Custom Machined Parts is a company dedicated to providing top-quality, custom machined parts to businesses across a wide range of industries. With their extensive experience, advanced capabilities, and commitment to innovation, the company continues to set the standard for excellence in precision engineering. Whether it’s a small prototype or a large production run, Custom Machined Parts has the expertise and resources to meet the unique needs of their clients and deliver exceptional results.

High-Quality CNC Machining Parts: Everything You Need to Know

Announces Expansion of Cnc Machining Parts Production Facility - , a leading manufacturer of precision machined parts and components, has announced plans to expand its CNC machining parts production facility. The expansion comes in response to increased demand for high-quality, custom CNC machined parts across a wide range of industries.The company's CNC machining capabilities are a crucial part of its overall manufacturing operations, allowing for the production of complex, precise parts that are used in a variety of applications, including aerospace, automotive, medical, and more. With the expansion of its CNC machining facility, will be able to better meet the needs of its customers and continue to deliver high-quality, reliable parts with quick turnaround times."We are excited to announce the expansion of our CNC machining parts production facility," said , at . "This investment will allow us to increase our capacity and capabilities, enabling us to better serve our customers and meet the growing demand for custom CNC machined parts."In addition to expanding its CNC machining facility, is also committed to investing in the latest technology and equipment to ensure that its parts meet the highest standards of quality and precision. The company has a team of highly skilled machinists and engineers who are dedicated to delivering top-notch parts that meet the exact specifications of each customer."We take great pride in our ability to create custom CNC machined parts that meet the unique needs of our customers," said . "Our team has the expertise and technology to produce parts with extremely tight tolerances and complex geometries, making us a trusted partner for precision machined components." offers a wide range of CNC machining services, including milling, turning, and grinding, as well as secondary operations such as deburring, anodizing, and assembly. The company is equipped to work with a variety of materials, including aluminum, steel, stainless steel, and titanium, and can accommodate both small and large production runs.As a company that is committed to continuous improvement, is dedicated to providing its customers with the highest level of service and quality. The expansion of its CNC machining facility is just one example of the company's ongoing efforts to enhance its capabilities and better serve its customers."We are always looking for ways to improve and grow as a company," said . "Expanding our CNC machining parts production facility is just one step in that direction, and we are excited to see the positive impact it will have on our ability to meet the needs of our customers."The expansion of 's CNC machining facility is expected to be completed within the next six months. In the meantime, the company remains fully operational and continues to fulfill orders for custom CNC machined parts.For more information about 's CNC machining services or to request a quote for custom parts, visit the company's website at www.companyname.com. The company looks forward to continuing to serve its customers with high-quality, precision machined parts and looks forward to the opportunities that the expanded facility will bring.

Newly Developed Metal Coating Offers Durable and Stylish Finish

Chromed Metal, a leading provider of high-quality metal finishing and plating services, has been making headlines in the manufacturing industry with its innovative and sustainable solutions for a wide range of industries. The company specializes in providing precision metal finishing, electroplating, and surface treatment solutions to enhance the performance, durability, and aesthetics of various metal components.Established over 20 years ago, Chromed Metal has built a strong reputation for delivering exceptional quality and customer service. With state-of-the-art facilities and a team of highly skilled engineers and technicians, the company has the expertise and capabilities to handle complex metal finishing projects for clients across the automotive, aerospace, electronics, medical, and other industries.One of Chromed Metal’s key strengths is its ability to tailor its services to meet the specific needs and requirements of its clients. Whether it’s a small batch of components or a large-scale production run, the company can accommodate a wide range of project sizes and specifications. From decorative chrome plating to functional coatings and corrosion protection, Chromed Metal offers a comprehensive suite of metal finishing solutions to address various application needs.In addition to its core metal finishing services, Chromed Metal is also committed to sustainability and environmental responsibility. The company has invested in advanced water treatment and waste management systems to minimize its environmental impact and ensure compliance with regulations. By implementing eco-friendly practices and using non-toxic chemicals and materials, Chromed Metal is able to offer its clients a greener and more sustainable metal finishing solution.The company’s dedication to quality and innovation has earned it the trust and loyalty of its clients, who rely on Chromed Metal for their most critical metal finishing needs. From enhancing the aesthetic appeal of automotive trim and accessories to providing corrosion protection for critical aerospace components, the company’s services play a vital role in ensuring the performance and longevity of various metal products.Chromed Metal’s commitment to excellence is further demonstrated by its investment in research and development. The company continually explores new technologies and processes to improve its metal finishing capabilities and stay ahead of industry trends. By staying at the forefront of innovation, Chromed Metal is able to offer its clients cutting-edge solutions that meet the evolving demands of the market.Furthermore, Chromed Metal prides itself on its responsive and collaborative approach to customer service. The company works closely with its clients to understand their unique requirements and provide customized solutions that meet their specific needs. From initial consultation to final delivery, Chromed Metal’s team remains in constant communication with its clients to ensure that their expectations are met and exceeded.As Chromed Metal continues to expand its footprint in the metal finishing industry, the company remains committed to upholding its core values of quality, innovation, and sustainability. With a focus on delivering superior results and exceeding customer expectations, Chromed Metal is well-positioned to remain a trusted partner for metal finishing solutions for years to come.In conclusion, Chromed Metal’s dedication to excellence, innovation, and sustainability has solidified its position as a leading provider of metal finishing services. With its advanced capabilities, commitment to quality, and customer-centric approach, the company is poised to continue driving positive impact across a wide range of industries. As the demand for high-quality metal finishing solutions grows, Chromed Metal remains a go-to partner for businesses seeking reliable and innovative services to enhance the performance and aesthetics of their metal components.

Top Quality Precision Products for Your Needs

High Precision Products, a leading manufacturing company in the precision engineering industry, has recently made a significant breakthrough in the development of a groundbreaking new product. The company, known for its high-quality and innovative solutions, has been working tirelessly to create cutting-edge products that will revolutionize the industry.With a focus on precision and accuracy, High Precision Products has always been at the forefront of technological advancements. The company’s dedication to innovation and excellence has made it a trusted name in the industry, and its latest development is set to further solidify its reputation as a pioneer in the field of precision engineering.The new product, which is the result of extensive research and development, promises to offer unparalleled levels of accuracy and performance. This breakthrough is expected to have a transformative impact on a wide range of industries, including aerospace, automotive, and medical technology.High Precision Products’ commitment to excellence is evident in every aspect of its operations. From its state-of-the-art manufacturing facilities to its highly skilled team of engineers and technicians, the company spares no effort in ensuring that its products meet the highest standards of quality and precision.The company’s dedication to innovation and excellence is reflected in its continuous investment in research and development. This commitment has enabled High Precision Products to stay ahead of the competition and consistently deliver cutting-edge solutions to its customers.In addition to its technical prowess, High Precision Products is also known for its unwavering commitment to customer satisfaction. The company places a strong emphasis on understanding the unique needs of its clients and providing tailor-made solutions to meet their specific requirements.High Precision Products’ new product is poised to further strengthen its position as a market leader in the precision engineering industry. The company’s track record of delivering high-quality, reliable solutions has earned it the trust and respect of its customers, and this latest development is expected to enhance its reputation even further.With its sights set on the future, High Precision Products is committed to continuing its tradition of excellence and innovation. The company is constantly exploring new opportunities and pushing the boundaries of what is possible in the field of precision engineering.High Precision Products’ new product is a testament to its dedication to pushing the envelope and setting new standards in the industry. With its unparalleled levels of accuracy and performance, this groundbreaking development is set to redefine the way precision engineering is done.As the company prepares to unveil its latest innovation to the world, industry experts and customers alike are eagerly awaiting the opportunity to experience the capabilities of High Precision Products’ new product firsthand. With its reputation for excellence and a track record of delivering cutting-edge solutions, the company is well-positioned to make a significant impact with this groundbreaking development.In conclusion, High Precision Products’ latest breakthrough represents a milestone in the field of precision engineering. With its unwavering commitment to excellence and a track record of delivering high-quality solutions, the company is poised to revolutionize the industry once again. As the company prepares to unveil its latest innovation, the future looks bright for High Precision Products and the customers who will benefit from its groundbreaking new product.

Top Machined Parts Manufacturers in the Industry

Machined Parts Manufacturers, a leading provider of high-quality precision machined parts, has been making waves in the manufacturing industry with its dedication to quality, innovation, and customer satisfaction. With a focus on delivering exceptional products and services, Machined Parts Manufacturers has become a top choice for businesses in need of reliable and expertly-crafted components for a wide range of applications.The company's commitment to excellence is evident in every aspect of its operations, from the meticulous attention to detail in the manufacturing process to the unparalleled level of customer service provided to clients. With a team of highly skilled engineers, technicians, and machinists, Machined Parts Manufacturers has the expertise and resources to handle even the most complex and demanding projects with ease.Machined Parts Manufacturers specializes in producing a diverse range of precision machined parts, including complex components for the aerospace, automotive, medical, and defense industries. The company's state-of-the-art facilities are equipped with the latest CNC machining equipment, allowing for the production of parts with incredibly tight tolerances and exacting specifications. Whether it's low volume, high mix, or high volume production, Machined Parts Manufacturers has the capabilities to meet the unique needs of each customer.In addition to its manufacturing capabilities, Machined Parts Manufacturers offers a range of value-added services, including engineering support, prototyping, and assembly. By providing comprehensive solutions from concept to completion, the company ensures that its clients have access to the resources they need to bring their projects to life.Moreover, Machined Parts Manufacturers is dedicated to maintaining the highest standards of quality and compliance in its operations. The company is ISO 9001 certified, demonstrating its commitment to meeting and exceeding international quality management standards. Additionally, its adherence to strict quality control processes and in-house inspection protocols ensures that every part produced meets the most rigorous quality requirements.With a keen focus on innovation and continuous improvement, Machined Parts Manufacturers is constantly investing in new technologies and processes to enhance its capabilities and stay ahead of the curve. The company's dedication to staying at the forefront of industry trends and advancements allows it to provide cutting-edge solutions to its customers while maintaining the highest levels of efficiency and cost-effectiveness.As a testament to its success, Machined Parts Manufacturers has earned a reputation for delivering excellence in every aspect of its operations. The company's commitment to customer satisfaction and its unwavering dedication to quality have earned it the trust and loyalty of a diverse clientele from around the globe. Customers consistently rely on Machined Parts Manufacturers to deliver precision parts that meet and exceed their expectations, time and time again.Looking ahead, Machined Parts Manufacturers is poised for continued growth and success in the manufacturing industry. With a solid foundation built on a commitment to quality, innovation, and customer satisfaction, the company is well positioned to continue its trajectory of expansion and distinction in the marketplace. As businesses continue to seek reliable and expertly-crafted precision machined parts, Machined Parts Manufacturers stands ready to meet and exceed their needs with its unwavering dedication to excellence.

Advanced CNC Manufacturing Technology: A Comprehensive Guide

CNC Manufacturing Technology has revolutionized the manufacturing industry with its advanced precision machining capabilities. By utilizing computer numerical control (CNC) machines, manufacturers are able to produce high-quality, complex parts with incredible accuracy and efficiency. This technology has significantly improved the overall manufacturing process, leading to faster production times, reduced costs, and increased product quality.With the integration of CNC Manufacturing Technology, companies such as {} have been able to streamline their production processes and stay ahead of the competition. By investing in state-of-the-art CNC machines, {} has been able to take on more complex projects and produce parts that meet the highest industry standards.One of the key advantages of CNC Manufacturing Technology is its ability to automate the manufacturing process. With CNC machines, manufacturers can program precise instructions into the system, allowing for consistent and repeatable production. This automation not only increases productivity but also reduces the risk of human error, resulting in fewer defects and higher quality products.In addition to automation, CNC Manufacturing Technology also offers versatility in production capabilities. CNC machines can be used to create a wide range of parts and components, from small intricate pieces to larger, more complex structures. This flexibility allows manufacturers to tackle a diverse set of projects and meet the needs of various industries.Furthermore, CNC Manufacturing Technology enables manufacturers to optimize their production resources and minimize waste. With the precise control offered by CNC machines, material usage is minimized, and the overall manufacturing process becomes more sustainable. This not only benefits the environment but also helps companies save on production costs.Moreover, with the rise of Industry 4.0, CNC Manufacturing Technology has become even more advanced. The integration of smart technologies and data analytics has further enhanced the capabilities of CNC machines, allowing for real-time monitoring and optimization of the manufacturing process. This has enabled companies like {} to stay at the forefront of technological advancements in the industry.The adoption of CNC Manufacturing Technology has had a significant impact on {}'s ability to manufacture high-quality products in a timely manner. By leveraging the precision and efficiency of CNC machines, {} has been able to meet the evolving demands of its customers and stay competitive in the market. The company's commitment to investing in advanced manufacturing technologies has solidified its position as an industry leader.Looking ahead, the future of CNC Manufacturing Technology looks promising. As advancements continue to be made in robotics, artificial intelligence, and automation, the capabilities of CNC machines will only grow further. This will undoubtedly lead to even more efficient and precise manufacturing processes, ultimately benefiting companies like {} and the manufacturing industry as a whole.In conclusion, CNC Manufacturing Technology has revolutionized the manufacturing industry, offering precision, automation, versatility, and sustainability. Through the integration of CNC machines, companies like {} have been able to elevate their production capabilities, meet customer demands, and stay ahead of the competition. As technology continues to advance, the potential for CNC Manufacturing Technology in the manufacturing industry is endless, promising an exciting future for production efficiency and product quality.

High-Quality CNC Machining Service in China for Your Manufacturing Needs

China CNC Machining Service Industry Continues to Expand and InnovateChina has long been known for its strong manufacturing industry, and the country's CNC machining service sector is no exception. With the increasing demand for high-precision parts and components in various industries, China's CNC machining service providers have been continuously expanding and innovating to meet the market's needs.One of the leading CNC machining service providers in China, [], has been at the forefront of this industry development. With its state-of-the-art facilities and cutting-edge technology, the company has been delivering high-quality precision machining solutions to its global clientele.Established in [], [] has quickly become a trusted partner for businesses in various sectors, including aerospace, automotive, medical, and telecommunications. The company's commitment to quality, reliability, and continuous improvement has helped it build a solid reputation in the industry.One of the key factors driving the growth of China's CNC machining service industry is the increasing demand for custom-made components in various high-tech industries. As companies strive to stay ahead of the competition by introducing new products and technologies, the need for precise and reliable parts has become more critical than ever.With its extensive experience and expertise, [] has been able to meet the complex requirements of its clients, providing them with tailored solutions that meet their specific industry needs. The company's dedication to research and development has enabled it to stay ahead of the curve, offering advanced machining techniques and materials to its customers.In addition to the growing demand for custom precision parts, the rapid development of the electric vehicle (EV) industry has also played a significant role in driving the expansion of China's CNC machining service sector. The increasing adoption of EVs has created a surge in the demand for high-precision components, such as battery housings, motor parts, and charging infrastructure.As a result, CNC machining service providers like [] have been heavily investing in advanced equipment and technologies to meet the specific requirements of the EV industry. By offering specialized machining capabilities for EV-related components, the company has positioned itself as a go-to partner for EV manufacturers looking for reliable and high-quality machining solutions.Moreover, the global trend towards automation and robotics has further fueled the growth of China's CNC machining service industry. As more industries automate their production processes, the demand for precision-machined parts for robots and automation equipment has continued to increase.Recognizing this market opportunity, [] has been actively expanding its capabilities to serve the evolving needs of the automation industry. The company's investment in advanced automation technologies has allowed it to offer a wide range of precision-machined components for robotic arms, motion control systems, and other automation equipment.The COVID-19 pandemic has also accelerated the adoption of automation and robotics in various industries, as businesses seek to minimize human interaction and improve production efficiency. As a result, the demand for CNC machining services that can support the automation industry has remained robust, driving further growth in the sector.Looking ahead, China's CNC machining service industry is poised for continued expansion and innovation, driven by the increasing demand for high-precision parts in key industries such as aerospace, automotive, EV, and automation. With companies like [] leading the way with their advanced capabilities and dedication to excellence, China's CNC machining service sector is well-positioned to remain a key player in the global manufacturing landscape.

Expert Guide to Gear Cutting: Everything You Need to Know

Custom Gear Cutting, a leading manufacturing company in the mechanical engineering industry, is proud to announce the expansion of its services to meet the increasing demand for precision gear cutting solutions. With over {number of years} years of experience in the industry, Custom Gear Cutting has established a strong reputation for delivering high-quality, reliable, and cost-effective gear cutting services to a wide range of clients.Custom Gear Cutting specializes in the design and production of custom gears, splines, and sprockets for various applications including automotive, aerospace, industrial machinery, and more. The company's state-of-the-art manufacturing facility is equipped with the latest gear cutting technology and machinery, allowing them to produce precision-engineered gears that meet the highest industry standards.The company's team of highly skilled engineers and technicians are dedicated to providing innovative and tailored solutions to meet their clients' specific gear cutting needs. Whether it's a complex gear geometry, tight tolerances, or unique material requirements, Custom Gear Cutting has the expertise and capabilities to deliver customized gear cutting solutions that exceed expectations.In addition to their custom gear cutting services, Custom Gear Cutting also offers a range of value-added services including gear hobbing, gear shaping, gear grinding, and gear inspection. This comprehensive approach allows the company to provide end-to-end gear manufacturing solutions, from design and prototyping to production and quality control.With a commitment to customer satisfaction and continuous improvement, Custom Gear Cutting is constantly investing in new technologies and process enhancements to ensure that they remain at the forefront of the industry. This dedication to innovation and excellence has enabled the company to build long-standing relationships with a diverse portfolio of clients, from small businesses to multinational corporations."We are excited to expand our gear cutting capabilities to better serve the evolving needs of our customers," said [spokesperson name], [job title] at Custom Gear Cutting. "As a customer-focused company, we are dedicated to providing tailored solutions that address the unique challenges of our clients. Our team is passionate about delivering top-quality products and services that drive success and innovation in the industry."Custom Gear Cutting's commitment to quality and customer satisfaction is evident in their ISO [insert ISO certification number] certification, which demonstrates their adherence to rigorous quality management standards. This certification is a testament to the company's dedication to excellence and their ability to consistently deliver superior products and services.As Custom Gear Cutting continues to expand its capabilities and offerings, the company remains committed to upholding its core values of integrity, innovation, and reliability. With a focus on delivering exceptional gear cutting solutions and building lasting partnerships with their clients, Custom Gear Cutting is poised to remain a trusted leader in the industry for years to come.For more information about Custom Gear Cutting and their comprehensive gear cutting services, visit their website at www.customgearcutting.com.

Quality Injection Molded Plastic Parts for Your Business Needs

Established in [insert year], [company name] is a leading manufacturer of precision CNC plastic parts. With a state-of-the-art facility and a team of highly skilled engineers and technicians, the company is at the forefront of the industry, delivering high-quality plastic components to a wide range of industries including automotive, aerospace, medical, and electronics.Utilizing advanced CNC machining technology, [company name] is able to produce complex plastic parts with tight tolerances and high precision. The company's expertise in working with a variety of plastic materials, including [list some materials], allows them to meet the unique needs of each customer, whether it's producing prototypes or large-scale production runs.One of the key advantages of [company name]'s CNC plastic parts is the ability to create intricate designs and geometries that would be difficult or impossible to achieve using traditional manufacturing methods. This capability opens up new possibilities for product development and innovation, giving customers a competitive edge in their respective markets.In addition to its manufacturing capabilities, [company name] is committed to quality and customer satisfaction. The company adheres to strict quality control measures throughout the production process to ensure that every part meets the highest standards. From the initial design phase to final inspection, [company name] is dedicated to delivering parts that meet or exceed customer expectations.Furthermore, [company name] places a strong emphasis on customer relationships and collaboration. The company works closely with customers from the early stages of a project, providing expertise and guidance to optimize designs for manufacturability and cost-effectiveness. This proactive approach helps to streamline the production process and ensure that customers receive the best possible solutions for their plastic part needs.Despite the challenges posed by the global pandemic, [company name] has continued to thrive and expand its capabilities. The company has invested in the latest CNC technology and equipment, increasing its capacity and efficiency to meet the growing demand for high-quality plastic parts. Additionally, [company name] has implemented strict safety protocols to protect its workforce and maintain uninterrupted operations.[Company name]'s commitment to sustainability is also reflected in its manufacturing processes. The company has implemented eco-friendly practices to reduce waste and minimize its environmental impact. This includes the use of recyclable materials and energy-efficient equipment, as well as responsible waste management and recycling programs.Looking ahead, [company name] is poised for further growth and success in the CNC plastic parts industry. The company is continuously exploring new technologies and materials to expand its capabilities and offer innovative solutions to its customers. With a solid reputation for quality, reliability, and innovation, [company name] is well-positioned to meet the evolving needs of the market and remain a leader in the manufacturing of precision plastic parts.

Top Advantages of High Precision Machining Centers for Superior Results

High-Precision Machining Center Revolutionizes Manufacturing Industry In today's competitive manufacturing landscape, precision and accuracy have become paramount for businesses looking to thrive. This need for precision has further intensified with growing demand for complex and intricate parts across various industries. To address this ever-increasing demand, a cutting-edge high-precision machining center has been developed, offering unparalleled accuracy and efficiency to revolutionize the manufacturing sector.The high-precision machining center, affectionately referred to as the HPMC, represents a groundbreaking advancement in machining technology. Designed to offer unmatched accuracy and versatility, this state-of-the-art solution ensures that even the most intricate parts are manufactured to precision, meeting the stringent quality requirements of modern industries. The HPMC's innovative and intelligent features provide manufacturers with the ability to tackle complex projects effortlessly, saving time and resources while achieving exceptional results.One of the key distinguishing features of this high-precision machining center is its advanced CNC control system. Leveraging cutting-edge technology, this control system allows for seamless programming and execution of machining operations with unparalleled precision. By providing operators with a user-friendly interface and an array of innovative features, this system ensures that the HPMC can handle a wide range of machining tasks efficiently and with utmost accuracy.Another standout characteristic of the HPMC is its robust construction and cutting-edge manufacturing techniques. Built with high-quality components, this machining center offers exceptional stability and rigidity, reducing vibrations and ensuring superior accuracy. Moreover, its innovative design minimizes heat generation during operation, which further contributes to its high-precision capabilities.In addition to its remarkable precision, the HPMC's versatility is yet another aspect that sets it apart from its competitors. With a multitude of available tooling options, the machining center can effortlessly handle a wide range of materials, from metals like steel and aluminum to composites and plastics. Its ability to accommodate various machining techniques, such as milling, drilling, and turning, makes it a highly versatile solution that can meet the diverse needs of manufacturers in different industries.Perhaps one of the most significant advantages of the HPMC is its potential to enhance productivity and efficiency. Equipped with innovative automation features and real-time monitoring capabilities, this machining center optimizes production processes and minimizes downtime. The intelligent workload management system ensures optimal operation, reducing idle time and maximizing productivity. Additionally, the HPMC's ability to integrate seamlessly with other Industry 4.0 technologies streamlines the entire manufacturing workflow, establishing a connected and efficient production environment.The importance of high-precision machining centers cannot be overstated. Their role in supporting the manufacturing industry is vital, as they enable businesses to meet the ever-increasing demands for accuracy, efficiency, and productivity. With the introduction of the HPMC, manufacturers can now stay ahead of the competition by delivering high-quality products with unmatched precision and efficiency.Leading the charge towards a new era of manufacturing excellence, the HPMC promises to transform the industry landscape. By combining state-of-the-art technology, unrivaled precision, and exceptional versatility, this machining center provides an all-encompassing solution for manufacturers striving for excellence. With the HPMC, businesses can confidently tackle complex projects, meet industry demands, and ensure their place at the forefront of the manufacturing industry.