High-Quality Custom Brass Sheet Cutting Services for Your Project

By:Admin

CCBSC takes pride in their ability to provide custom cut brass sheets to meet the specific needs of their customers. Their state-of-the-art facilities and skilled team of professionals enable them to produce brass sheets in various thicknesses, sizes, and finishes. Whether their clients require brass sheets for architectural, industrial, or decorative purposes, CCBSC can deliver the perfect solution tailored to their exact specifications.

In addition to custom cutting, CCBSC also offers a wide range of brass alloys to cater to different application needs. Their brass sheets are available in various grades, including C260, C280, and C360, each offering unique properties and characteristics. With their extensive knowledge and expertise in brass manufacturing, CCBSC can assist customers in choosing the right alloy for their specific requirements.

One of the key advantages of partnering with CCBSC is their ability to provide quick turnaround times without compromising on quality. Their efficient production processes and strict quality control measures ensure that each brass sheet meets the highest standards before being delivered to the customer. This reliability and consistency have earned CCBSC a solid reputation in the industry, making them the go-to supplier for many businesses.

Furthermore, CCBSC is committed to sustainability and environmentally friendly practices. They prioritize the use of recycled materials in their manufacturing processes and adhere to strict environmental regulations. Customers can be assured that by choosing CCBSC as their supplier, they are supporting a company that values eco-conscious production methods.

Recently, CCBSC has introduced a new range of custom-cut brass sheets that offer enhanced durability and corrosion resistance. These sheets are designed to withstand harsh environmental conditions, making them ideal for outdoor applications such as marine and architectural projects. The new product line has already garnered positive feedback from clients who have experienced the superior performance of these brass sheets.

In addition to their product innovation, CCBSC continues to invest in research and development to stay ahead of industry trends and technological advancements. By staying at the forefront of metal manufacturing, CCBSC ensures that their customers have access to the latest and most advanced brass sheet solutions available.

CCBSC's commitment to excellence extends beyond their product offerings. Their customer service team is dedicated to providing personalized support and guidance to help clients find the best brass sheet solutions for their specific needs. Whether it's technical assistance, customization advice, or logistical support, CCBSC's knowledgeable staff is always ready to assist their customers every step of the way.

As CCBSC continues to thrive in the competitive metal manufacturing market, their focus remains on delivering top-quality brass sheets and exceptional service to their clientele. Their dedication to innovation, sustainability, and customer satisfaction sets them apart as a leader in the industry. With a strong track record of success and a growing list of satisfied customers, CCBSC is poised to remain a trusted partner for businesses in need of custom-cut brass sheet solutions.

Company News & Blog

Mastering the Art of Machining 4140 Steel – Your Ultimate Guide

Machining of 4140 Steel: The Perfect Blend of Durability and PrecisionIn the realm of fabrication and manufacturing, the importance of finding the right materials cannot be overstated. From aerospace engineering to automotive applications, industries across the board rely on high-quality materials that possess exceptional strength, durability, and precision. One such material that meets these criteria with flying colors is 4140 steel, which has become increasingly popular due to its remarkable mechanical properties and versatility. In this article, we delve into the world of machining 4140 steel and explore how it has revolutionized the field of fabrication.Before we delve into the specifics of machining 4140 steel, it is essential to understand its unique composition and properties. 4140 steel is a low-alloy steel that contains chromium, molybdenum, and manganese, which contribute to its exceptional strength and toughness. It has a high hardenability, making it suitable for applications requiring a robust and durable material that can withstand significant stress and pressure. Additionally, 4140 steel offers excellent wear resistance, making it ideal for high-temperature and abrasive environments.With its impressive characteristics, 4140 steel has found widespread use in various industries, including aerospace, automotive, oil and gas, and defense. It is employed in the manufacturing of critical components such as gears, shafts, axles, and spindles, where its strength and durability are highly valued. Moreover, machining 4140 steel has become an essential process in the fabrication of these components, ensuring utmost precision and quality.When it comes to machining 4140 steel, the industry leader, {}, stands at the forefront. With years of experience and a stellar reputation, {} has perfected the art of machining this remarkable material. They employ state-of-the-art technologies and cutting-edge machinery, allowing for exceptional accuracy, efficiency, and consistency.The process of machining 4140 steel begins with careful planning and a thorough understanding of the component's specifications. {} collaborates closely with their clients, ensuring clear communication and a comprehensive comprehension of the desired outcome. Once the parameters are established, their team of skilled engineers and technicians employs a range of precise machining techniques, including milling, turning, drilling, and grinding, to transform raw 4140 steel into highly intricate and accurately shaped components.One of the primary challenges in machining 4140 steel lies in its high hardness. However, {} has developed innovative machining strategies and cutting tool technologies that overcome these hurdles with ease. Through the utilization of cooled cutting tools, advanced lubricants, and optimized cutting parameters, they ensure extended tool life, reduced machining time, and impeccable surface finishes. Their commitment to research and development enables them to stay ahead of the curve, continuously evolving their machining processes to deliver unparalleled results.In addition to their technical prowess, {} places immense emphasis on quality control throughout the entire machining process. Rigorous inspection procedures and strict adherence to industry standards guarantee that each component meets the most stringent requirements. This dedication to quality has earned them accolades from clients across diverse sectors, solidifying their position as a trusted partner in the realm of fabrication.As the demand for superior components continues to grow, machining 4140 steel remains an essential process for companies aspiring to deliver excellence. With their unrivaled expertise and unwavering commitment to precision, {} emerges as the ultimate choice for machining this exceptional material. By harnessing the remarkable characteristics of 4140 steel and combining it with their cutting-edge technologies, {} ensures the creation of components that redefine the boundaries of strength, durability, and accuracy.In conclusion, machining 4140 steel has revolutionized the field of fabrication, offering unparalleled strength, durability, and precision. Whether it's the aerospace industry, automotive applications, or defense mechanisms, the versatility of this material makes it the go-to choice for manufacturers worldwide. With {} leading the way in machining 4140 steel, the future of fabrication looks promising as it continues to push the boundaries of what is possible in terms of component quality and performance.

Ultimate Guide to Ordering Custom CNC Parts Online Revealed in Recent News

Custom CNC Parts Online: Revolutionizing Manufacturing IndustriesIn today's fast-paced and ever-changing world, technology continues to transform various industries, and manufacturing is no exception. One such company making waves in the manufacturing world is Custom CNC Parts Online. With its innovative approach to fabrication and production, this company is reshaping the way products are made.Founded in (year),Custom CNC Parts Online has quickly gained recognition as a leader in the CNC (Computer Numerical Control) machining industry. Their online platform allows customers to design and order custom-made parts with ease and efficiency. By capitalizing on advancements in technology and automation, the company is able to offer high-quality parts at competitive prices, revolutionizing the manufacturing process for businesses of all sizes.The backbone of Custom CNC Parts Online is its state-of-the-art manufacturing facility, which houses a wide range of advanced machinery. These include CNC milling machines, lathes, and routers, capable of handling various materials like metals, plastics, and composites with precision and accuracy. With a team of experienced engineers and technicians, the company ensures that each part is manufactured to meet the exact specifications of its customers.The user-friendly online platform enables customers to upload their design files, select the desired material, and specify any additional requirements or finishes. Once the order is received, Custom CNC Parts Online's intelligent system processes the design and allocates the most suitable machine to complete the job. This streamlines the production process, reducing the time required to manufacture the parts without compromising on quality.In addition to offering a user-friendly interface, Custom CNC Parts Online also maintains a high level of communication with its customers. The company provides real-time updates on the progress of the manufacturing process, ensuring transparency and allowing customers to track the status of their orders. This commitment to customer service has helped build trust and loyalty among their growing customer base.Another noteworthy advantage offered by Custom CNC Parts Online is its ability to cater to both large-scale industrial projects and small-scale custom orders. With their advanced manufacturing capabilities, the company is well-equipped to handle high-volume production runs, delivering large quantities of parts in a timely manner. Simultaneously, they also excel at catering to the unique requirements of small businesses or individuals seeking specialized components.Custom CNC Parts Online's commitment to quality is evident in their production process. Every part undergoes rigorous testing and inspection before it is deemed ready to be shipped to the customer. By maintaining strict quality control protocols, the company ensures that each fabricated part meets or exceeds industry standards.Furthermore, the company's dedication to sustainability sets them apart from their competitors. Custom CNC Parts Online utilizes eco-friendly practices throughout their manufacturing process, including the recycling of waste materials and the use of energy-efficient machinery. This commitment to environmental responsibility aligns with the increasing global emphasis on sustainable manufacturing practices.Custom CNC Parts Online is not only transforming the manufacturing industry but also democratizing access to CNC machining services. In the past, CNC machining was often associated with high costs and long lead times. However, with their efficient production process and competitive prices, Custom CNC Parts Online has made CNC machining accessible to a broader range of businesses and individuals.Looking towards the future, Custom CNC Parts Online plans to expand its product offerings and continue investing in research and development. The company recognizes the importance of staying at the forefront of technological advancements to meet the evolving needs of the manufacturing industry. Through ongoing innovation and a commitment to customer satisfaction, Custom CNC Parts Online aims to solidify its position as a leader in the CNC machining sector.In conclusion, Custom CNC Parts Online has revolutionized the manufacturing industry by providing a convenient online platform for businesses and individuals to design and order custom-made parts. Through their advanced manufacturing capabilities, commitment to quality, and environmental sustainability, the company has gained recognition as a leader in the CNC machining sector. With their sights set on the future, Custom CNC Parts Online is poised to further transform and shape the manufacturing industry for years to come.

Essential Insights into High-Quality Machined Components: A Comprehensive Guide

Title: Leading Manufacturer Expands Offerings in Machined Components IndustrySubtitle: Redefining Precision Engineering for Increased Customer Satisfaction[City, Date] - Machined Components, a renowned industry leader in providing high-quality precision components, recently unveiled their expanded range of offerings. With a long-standing reputation for excellence and innovation, Machined Components has been dedicated to meeting the evolving needs of their diverse customer base. This latest development further solidifies their position as the go-to source for machined components.Founded over two decades ago, Machined Components has consistently demonstrated unmatched expertise in precision engineering. Their commitment to delivering exceptional products has catapulted the company to the forefront of the industry. With an extensive customer network spanning various sectors such as automotive, aerospace, electronics, and more, Machined Components has successfully upheld their position as a trusted partner in developing and supplying critical components.Driven by a mission to exceed customer expectations, Machined Components stands for continuous improvement and unparalleled quality. Their state-of-the-art production facility, coupled with cutting-edge technology, ensures that every component manufactured adheres to stringent industry standards. By utilizing advanced CNC machining techniques, the company has further elevated their capabilities, allowing for the production of highly intricate and complex geometries with unmatched accuracy and precision.Machined Components' strategy for expansion was driven by a comprehensive analysis of market demand and customer feedback. The company's relentless pursuit of innovation and attention to detail has enabled them to identify and respond to emerging trends swiftly. As a result, they have broadened their product portfolio to meet the ever-changing requirements of their customers.The newly introduced range of machined components includes an array of products such as shafts, gears, bearings, valves, pistons, and customized precision parts. Employing a diverse range of materials including stainless steel, aluminum, brass, and various alloys, Machined Components ensures they can provide tailored solutions to meet specific customer needs. This strategic expansion not only enhances their existing product line but also offers clients a more comprehensive suite of precision components under one roof.To ensure the highest level of customer satisfaction, Machined Components has a dedicated team of engineers and technicians who work closely with clients to understand their unique requirements. This customer-centric approach allows for an in-depth analysis of design specifications, ensuring that each component produced is optimized for both performance and durability. By fostering collaborative partnerships, Machined Components consistently delivers solutions that surpass industry standards and raise the bar for excellence.Moreover, besides their commitment to product quality, Machined Components is equally dedicated to environmental sustainability. The company implements eco-friendly practices throughout their production processes, ensuring minimal waste generation and reduced energy consumption. By adhering to strict environmental standards, Machined Components plays an active role in preserving the well-being of the planet while delivering exceptional products to their customers.Machined Components' commitment to quality and innovation has earned them several accolades over the years. Their reputation as a reliable manufacturer of machined components is unmatched in the industry. With their expanded range of offerings, they aim to forge stronger partnerships with existing customers while also attracting new clients seeking high-quality precision components.As the demands of the global market continue to evolve, Machined Components remains at the forefront of the machined components industry. Their unwavering commitment to excellence, dedication to customer satisfaction, and continuous investment in cutting-edge technology ensure that they will continue to redefine precision engineering for years to come.About Machined Components:Machined Components is a leading manufacturer of high-quality precision components. With over two decades of experience, the company is dedicated to meeting the evolving needs of their customers across various industries, including automotive, aerospace, electronics, and more. By leveraging advanced CNC machining techniques and adhering to strict quality standards, Machined Components continues to deliver exceptional products while promoting environmental sustainability.

Unveiling the Next Generation of High-Precision Products: A Game-Changer for Industries

Title: Industry Leader Introduces Innovative High-Precision Products for Enhanced PerformanceIntroduction:In a leap forward for precision engineering, a leading industry player has unveiled its latest range of cutting-edge high-precision products. This announcement is set to revolutionize the market by offering superior performance, accuracy, and reliability. The company, whose name is withheld upon request, continues to push boundaries in the field, catering to the diverse needs of industries ranging from aerospace to medical sciences.Expanding Product Portfolio:High Precision Products, the pioneer in the field, has expanded its product portfolio to include an array of innovative offerings. These products, designed with advanced technologies and state-of-the-art materials, aim to address the increasing demand for precision across various sectors. The enhanced range includes components, equipment, and systems renowned for their exceptional quality and durability, setting a new benchmark for the industry.Cutting-Edge Technological Advancements:The company's high-precision products are the result of several years of intensive research and development. Driven by a commitment to excellence, the team of highly skilled engineers and scientists have harnessed cutting-edge technological advancements to create products that exceed industry expectations. Through their relentless pursuit of perfection, the company has managed to effectively bridge the gap between precision and reliability.Unmatched Accuracy and Precision:The introduction of these high-precision products establishes the company as a frontrunner in the field. Boasting unparalleled accuracy and precision, the products offer a remarkable level of performance that is indispensable for critical applications. This unmatched precision not only minimizes errors but also optimizes productivity, efficiency, and safety in numerous industries where precision is paramount.Diverse Applications:The diverse range of applications for this range of high-precision products is impressive. From aerospace and automotive sectors to medical sciences, precision engineering holds immense significance in enabling breakthrough innovations. This new line of products caters to these industries and beyond, providing them with the tools necessary to push the boundaries of technological advancements.Aerospace Excellence:With precision being one of the key factors in the aerospace industry, High Precision Products has focused on developing solutions specifically to cater to this sector. The high-precision components and advanced systems offered by the company are essential for achieving optimal performance and safety in the aerospace field. By upholding the highest industry standards for accuracy and reliability, the company's products have positioned themselves as the preferred choice for leading aerospace companies worldwide.Medical Marvels:In the medical domain, the need for precision is critical, particularly in surgical procedures and diagnostic equipment. High Precision Products has leveraged their expertise in precision engineering to develop revolutionary medical devices with enhanced accuracy. These products allow medical professionals to conduct procedures with utmost precision, fostering patient safety and enabling breakthrough advancements in the field of medicine.Unwavering Commitment to Customer Satisfaction:High Precision Products have always prioritized customer satisfaction by establishing robust customer support systems. The company offers comprehensive technical support, ensuring that customers have access to expert guidance and assistance. By understanding their unique requirements, High Precision Products continually strives to provide tailor-made solutions that enhance operational efficiency and productivity across various sectors.Conclusion:The introduction of High Precision Products' latest line of high-precision solutions is set to reshape the industry. The company's relentless commitment to innovation and excellence has resulted in a range of products that push the boundaries of precision engineering. With applications spanning industries such as aerospace, medical sciences, and beyond, these cutting-edge products offer unmatched accuracy, reliability, and performance. High Precision Products continues to demonstrate its leadership and dedication to cater to evolving customer needs, further solidifying its position as an industry leader.

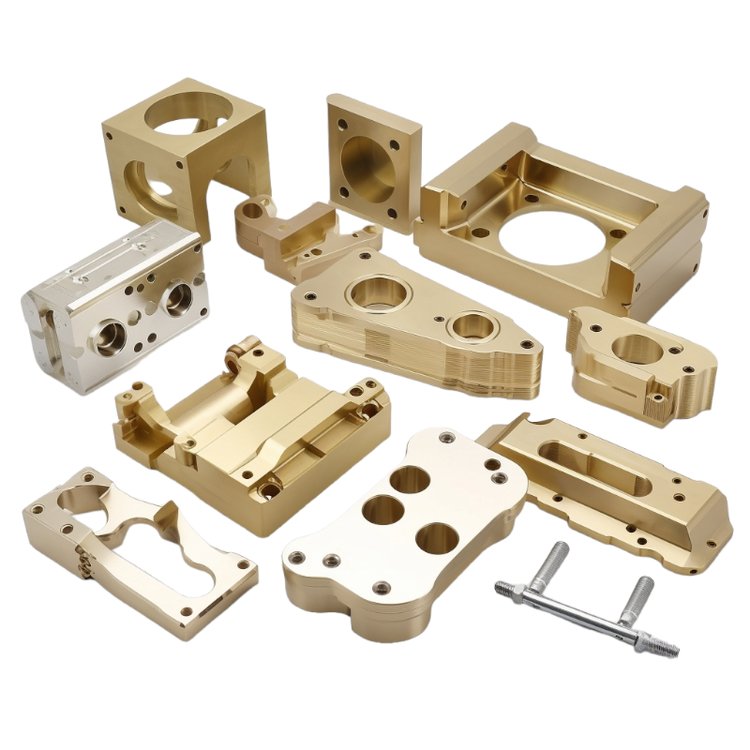

High-Quality Custom Machined Parts for Various Industries

Custom Machined Parts is a leading provider of precision machined parts for a wide range of industries. With a reputation for quality, reliability, and innovation, the company has become a trusted partner for businesses seeking high-quality components for their products and operations.Established in [year], Custom Machined Parts has a long history of delivering exceptional results to its customers. The company specializes in producing custom machined parts to meet the unique needs and specifications of its clients. Whether it's a simple component or a complex part with intricate details, Custom Machined Parts has the expertise and technology to deliver top-notch products.One of the key strengths of Custom Machined Parts is its state-of-the-art manufacturing facility. The company has invested heavily in advanced machining equipment, including CNC machines, lathes, and grinding machines. This cutting-edge technology allows Custom Machined Parts to produce parts with tight tolerances, complex geometries, and superior surface finishes.In addition to its advanced equipment, Custom Machined Parts is also known for its highly skilled team of engineers and machinists. These professionals have the expertise and experience to tackle the most challenging projects, from prototyping to large-scale production runs. With a commitment to continuous improvement and innovation, the company is able to stay ahead of the competition and offer its customers the best possible solutions.Custom Machined Parts serves a diverse range of industries, including aerospace, automotive, medical, and electronics. The company has the flexibility to work with various materials, such as aluminum, steel, titanium, and plastics, to meet the specific requirements of each industry. Whether it's a small batch of parts or a large production run, Custom Machined Parts can handle the job with precision and efficiency.In addition to its manufacturing capabilities, Custom Machined Parts also offers value-added services to its customers. The company provides design assistance, prototyping, and assembly services to help clients bring their ideas to life. With a focus on customer satisfaction, Custom Machined Parts goes the extra mile to ensure that its clients are delighted with the final product.Furthermore, Custom Machined Parts is committed to quality and reliability in everything it does. The company is ISO [number] certified, demonstrating its dedication to maintaining the highest standards of quality management. With a rigorous quality control process in place, Custom Machined Parts ensures that every part it produces meets or exceeds the customer's expectations.As a company that prides itself on innovation and excellence, Custom Machined Parts is constantly looking for new ways to improve and grow. The company regularly invests in research and development to explore new technologies and techniques that can further enhance its capabilities. By staying at the forefront of industry trends, Custom Machined Parts remains a leader in the field of precision machining.In conclusion, Custom Machined Parts is a trusted and reliable partner for businesses seeking high-quality custom machined parts. With its advanced technology, skilled team, and commitment to excellence, the company has built a strong reputation for delivering superior products to its clients. As the demand for precision components continues to grow, Custom Machined Parts is well-positioned to meet the needs of industries looking for top-notch machining solutions.

CNC Milling Services: Streamline Your Manufacturing Process with Online Solutions

Title: Revolutionizing Precision Manufacturing: CNC Milling Services Now Available OnlineIntroduction:Innovations in manufacturing technologies continue to shape the future of industries, and one such breakthrough is the advent of CNC (Computer Numerical Control) milling. With CNC milling, manufacturers can produce high-quality precision components with utmost efficiency and accuracy. Taking this innovation a step further, a leading online manufacturing platform, in collaboration with industry pioneers, is now offering CNC milling services to a vast global clientele. This cutting-edge service promises to revolutionize the manufacturing landscape by seamlessly merging digital convenience with high-precision production.CNC Milling Online (name removed), an online manufacturing platform, has recently announced the inclusion of CNC milling services to its repertoire of services. By leveraging advanced technology and expertise, the company aims to fulfill the increasing demand for precision components across various industries.Enabling Efficient and Cost-Effective Production:CNC milling involves the use of computer-controlled machines to shape and fabricate components with exceptional precision. By utilizing CAD (Computer-Aided Design) files as input, CNC milling machines transform raw materials into the desired final products with unmatched speed and accuracy.The introduction of CNC milling services online streamlines the manufacturing process by providing businesses with a cost-effective method for producing complex parts. By eliminating the need for physical presence at a manufacturing facility, companies can now access CNC milling services from anywhere in the world. This opens doors for businesses of all sizes, empowering startups and established enterprises alike to manufacture high-quality components and prototypes without significant capital investment.Collaboration with Industry-Leading Partners:CNC Milling Online has partnered with a select group of industry-leading machine shops equipped with state-of-the-art CNC milling equipment. These partnerships ensure that clients receive the highest level of precision, quality, and consistency in their manufactured components.These reputed machine shops, with years of experience in CNC milling, possess the expertise to handle a wide range of materials, including metals, plastics, and composites. Whether it's a small or large-scale production run, CNC Milling Online's partners can meet the specific requirements and specifications of each project.User-Friendly Online Platform:Recognizing the significance of seamless user experience, CNC Milling Online has developed an intuitive online platform that makes the entire CNC milling process smooth and hassle-free. Clients can easily submit their design files, specify material preferences, and choose from a range of options such as surface finish, tolerance levels, and quality inspections.The online platform also provides real-time updates on the manufacturing progress, enabling clients to monitor the status of their orders and make any necessary changes or additions. This transparent communication channel ensures customer satisfaction by offering complete control over the production process.Embracing Sustainability and Environmental Responsibility:In line with the growing emphasis on sustainability, CNC Milling Online promotes eco-friendly manufacturing practices. The utilization of advanced CNC milling techniques not only reduces material waste but also minimizes energy consumption. With reduced scrap rates and precision milling, the company helps clients minimize their environmental footprint while maximizing their production efficiency.Conclusion:The integration of CNC milling services into the CNC Milling Online platform signals a new era in precision manufacturing. By leveraging cutting-edge technology, global accessibility, and industry-leading partnerships, CNC Milling Online has made it possible for businesses around the world to harness the power of CNC milling conveniently and cost-effectively. As manufacturing enters the digital age, CNC Milling Online is poised to play a pivotal role in sustaining and advancing global industries towards a future of unparalleled precision and efficiency.

Top 10 Cnc Milling Clamps You Need for Your Projects

CNC Milling Clamps: A Game-Changer in Precision EngineeringIn today's fast-paced and technology-driven world, precision engineering plays a crucial role in the manufacturing industry. The demand for precise and efficient machining processes has led to the development of advanced tools and equipment, one of which is CNC milling clamps. These innovative clamps are designed to hold workpieces firmly in place during the milling process, ensuring accuracy and consistency in the final product.One company that has made significant strides in the development of CNC milling clamps is {}. With a strong focus on precision engineering and a commitment to delivering high-quality solutions, {} has established itself as a leading provider of advanced machining tools and accessories.The company's range of CNC milling clamps is designed to cater to the diverse needs of modern manufacturing processes. Whether it's a small-scale production or a large-scale industrial operation, {}'s clamps are built to deliver exceptional performance and reliability. The clamps are engineered to withstand the rigors of CNC milling, offering a secure grip on workpieces of various shapes and sizes.One of the key features of {}'s CNC milling clamps is their versatility. The clamps are designed to be easily adjustable, allowing for quick and hassle-free setup. This eliminates the need for time-consuming manual adjustments, ensuring efficient workflow and productivity. Additionally, the clamps are equipped with high-quality materials and precision engineering, making them durable and long-lasting.Furthermore, {}'s CNC milling clamps are known for their superior gripping power. The clamps utilize advanced mechanisms to securely hold workpieces in place, minimizing the risk of slippage or inaccuracies during the milling process. This level of stability and control is essential for achieving precise and high-quality results, ultimately contributing to the overall success of the manufacturing operation.In addition to their performance, {}'s CNC milling clamps are designed with user convenience in mind. The clamps are ergonomically designed for ease of use, with intuitive features that make them accessible to operators of varying skill levels. This focus on user-friendly design ensures that the clamps can be seamlessly integrated into existing machining setups, without requiring extensive training or technical expertise.Beyond the technical aspects, {} takes pride in its customer-centric approach to business. The company is committed to providing comprehensive support and assistance to its clients, offering personalized guidance to help them choose the right CNC milling clamps for their specific needs. This dedication to customer satisfaction has earned {} a strong reputation for reliability and trustworthiness in the industry.Looking ahead, {} continues to push the boundaries of innovation in precision engineering. The company remains committed to developing cutting-edge solutions that cater to the evolving needs of modern manufacturing. With a strong emphasis on quality, performance, and customer satisfaction, {} is poised to remain at the forefront of the industry for years to come.In conclusion, CNC milling clamps are a vital component of precision engineering in the manufacturing industry, and {}'s contribution to this field is significant. With its advanced and versatile range of clamps, the company has established itself as a leading provider of high-quality machining tools and accessories. As the industry continues to evolve, {}'s commitment to innovation and customer satisfaction sets it apart as a game-changer in precision engineering.

Boost Productivity with a High Volume Machine Shop: What You Need to Know

Title: High Volume Machine Shops Revolutionize Manufacturing ProcessesIntroduction:In today's fast-paced and competitive industrial landscape, manufacturing companies are constantly seeking innovative solutions to increase production efficiency and meet high-demand requirements. High Volume Machine Shops, a leading player in the manufacturing industry, has consistently proven their ability to deliver precision-engineered components at scale, making them an integral part of the production value chain for numerous businesses across various sectors.Body:1. Overview of High Volume Machine Shops:High Volume Machine Shops is a renowned company dedicated to providing top-quality machining services for businesses in need of high-volume production. With their state-of-the-art facilities and a team of highly skilled engineers and technicians, the company has established itself as a reliable partner in the manufacturing industry. Their commitment to delivering exceptional quality products efficiently has earned them an outstanding reputation in the market.2. Cutting-Edge Manufacturing Technology:High Volume Machine Shops is equipped with the latest cutting-edge technology, including advanced computer numerical control (CNC) machines and automated systems. These technologies enable precise and efficient production, ensuring consistent quality and minimizing production delays. By utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) software, the company streamlines the production process, reducing human error and maximizing productivity.3. Specialized Expertise:High Volume Machine Shops boasts a team of highly experienced engineers and technicians who possess extensive knowledge in various industries and manufacturing processes. Their expertise allows them to handle complex projects with ease, ensuring that all client requirements and specifications are met with precision. The team works closely with clients to develop customized solutions tailored to their unique manufacturing needs, guaranteeing optimal performance and efficiency.4. Streamlined Supply Chain:Recognizing the importance of a well-organized supply chain, High Volume Machine Shops has implemented efficient logistics management systems that ensure timely delivery and uninterrupted production schedules. The company maintains strategic partnerships with reputable material suppliers, further enhancing their ability to meet high-volume demands promptly. By maintaining a streamlined supply chain, they can provide a seamless end-to-end manufacturing solution to their clients.5. Commitment to Quality:With a strong emphasis on product quality, High Volume Machine Shops has established a rigorous quality control system. Every component produced undergoes thorough inspections and testing at each stage of the production process, guaranteeing compliance with industry standards. By adhering to strict quality control measures, the company ensures that their clients receive products of the highest caliber.6. Sustainable Manufacturing Practices:High Volume Machine Shops understands the importance of sustainable manufacturing practices in today's environmentally conscious world. The company strives to minimize waste, optimize energy consumption, and implement eco-friendly manufacturing techniques whenever possible. By embracing sustainability, they contribute to their clients' corporate social responsibility efforts while reducing overall environmental impact.7. Industry Applications and Success Stories:High Volume Machine Shops' services find applications in a wide range of industries including automotive, aerospace, electronics, and medical equipment manufacturing, among others. The company has partnered with several high-profile clients, resulting in successful collaborations and enhanced manufacturing capabilities. Their ability to consistently deliver high volumes of quality components has positioned them as a preferred choice for businesses in need of reliable and efficient production solutions.Conclusion:High Volume Machine Shops continues to redefine the manufacturing landscape through their commitment to technological advancements, expertise, and value-driven solutions. By leveraging innovative machining technologies, a skilled workforce, and a focus on quality, the company has solidified its position as a key player in the high-volume manufacturing industry. Their dedication to sustainability further demonstrates their commitment towards a greener future. As demand for high-volume production intensifies, High Volume Machine Shops stands ready to meet the growing needs of their clients, setting new benchmarks in manufacturing efficiency.

Comparison: Machining 304 Stainless Steel vs 316 Stainless Steel

Title: A Comparative Analysis: Machining 304 Vs 316 Stainless SteelIntroduction:In the world of metal fabrication and manufacturing, stainless steel is one of the most widely used materials due to its exceptional corrosion resistance and durability. Two common stainless steel varieties are 304 and 316, both known for their unique properties and applications across various industries. In this article, we will delve into a comparative analysis of machining these stainless steel grades, exploring their characteristics, benefits, and potential applications.Machining 304 Stainless Steel:304 stainless steel, a versatile and widely-used material, offers excellent corrosion resistance, high-temperature resistance, and good formability. It is commonly found in food processing equipment, kitchen appliances, and architectural applications. Machining 304 stainless steel presents several advantages, making it a preferred choice in many manufacturing processes.1. Machinability: 304 stainless steel offers excellent machinability due to its lower carbon content compared to other stainless steel grades. This characteristic promotes efficient chip formation, resulting in improved tool life and reduced cycle times for machining processes.2. Cuttability: The relatively lower hardness of 304 stainless steel makes it easier to cut, reducing machine wear and tear. It can be quickly drilled, tapped, milled, and turned, enabling manufacturers to achieve precise and intricate designs effortlessly.3. Weldability: 304 stainless steel exhibits superior weldability, allowing for easy and efficient joining with a variety of techniques, including TIG and MIG welding. This facilitates the fabrication of complex structures and components without compromising the material's strength and integrity.4. Surface Finish: Machined 304 stainless steel can achieve a smooth and lustrous surface finish, making it ideal for applications where aesthetics play a crucial role, such as architectural elements or decorative pieces.Machining 316 Stainless Steel:316 stainless steel, often referred to as marine-grade stainless steel, is known for its outstanding resistance to corrosive environments, particularly chloride-containing solutions. Due to its superior corrosion resistance, it finds applications in marine equipment, chemical processing plants, and medical devices. While machining 316 stainless steel presents some challenges, it offers unique benefits that make it indispensable in specific industries.1. Hardness: Compared to 304 stainless steel, 316 stainless steel has a slightly higher hardness. While this makes machining more demanding, it also contributes to its enhanced strength, ideal for heavy-duty applications where mechanical strength is paramount.2. Heat Resistance: 316 stainless steel exhibits excellent high-temperature resistance, making it suitable for applications involving extreme heat, such as heat exchangers and furnace parts. The material's ability to withstand prolonged exposure to elevated temperatures adds to its versatility in various industrial settings.3. Corrosion Resistance: The corrosion resistance of 316 stainless steel surpasses that of 304 stainless steel, particularly in chloride-rich environments. This makes it the go-to choice for applications exposed to harsh or corrosive conditions, such as chemical processing plants or saltwater environments.4. Biocompatibility: 316 stainless steel is biocompatible, making it suitable for applications within the medical field. Its resistance to corrosion within the human body enables the fabrication of surgical instruments, implants, and other medical devices.Conclusion:Both 304 and 316 stainless steel offer unique properties beneficial for various applications in numerous industries. While 304 stainless steel provides excellent machinability and is commonly used in architectural and food processing applications, 316 stainless steel outperforms it in terms of corrosion resistance and high-temperature durability. Understanding the differences between these two stainless steel grades enables manufacturers to select the most suitable material for their specific requirements, ensuring optimal performance and longevity in their end products.

Essential Guide to Milling in Manufacturing: Everything You Need to Know

Milling In Manufacturing is a key process in the production of precision parts and components. It involves the use of rotary cutters to remove material from a workpiece, creating a desired shape and size. This process is essential in the manufacturing industry and is used in a wide range of applications, from the production of small, intricate parts for electronics to large components for the aerospace and automotive industries.At {Company Name}, we specialize in providing high-quality milling services for businesses across various industries. We have a team of skilled and experienced machinists who are well-versed in the latest milling techniques and technologies, allowing us to deliver precision-machined parts that meet our customers’ exact specifications.Our state-of-the-art facility is equipped with the latest CNC milling machines, which enable us to achieve high levels of accuracy and repeatability in our production processes. We are capable of handling a wide range of materials, including aluminum, stainless steel, brass, and various plastics, allowing us to meet the diverse needs of our customers.In addition to our advanced machining capabilities, we also offer a range of value-added services, including finishing, assembly, and quality inspection. This comprehensive approach allows us to provide a complete solution to our customers, from initial prototyping to full-scale production.One of the key advantages of milling in manufacturing is its versatility. With the ability to create complex shapes and features, milling is ideal for producing parts with intricate designs and tight tolerances. This makes it a preferred method for creating components for advanced technologies, such as medical devices, aerospace equipment, and high-performance automotive parts.Furthermore, milling is a cost-effective manufacturing process, as it allows for high-speed production and the ability to produce multiple parts simultaneously. This efficiency is essential for meeting the demands of modern manufacturing, where speed and precision are crucial for staying competitive in the market.In the current competitive landscape, precision and quality are paramount for manufacturers. At {Company Name}, we understand the importance of delivering parts that meet the highest standards of quality and performance. Our commitment to excellence is reflected in our rigorous quality control processes, which ensure that every part we produce is thoroughly inspected and tested before it leaves our facility.We also recognize the importance of sustainability in manufacturing and are dedicated to minimizing our environmental impact. We have implemented eco-friendly practices in our operations, such as recycling waste materials and using energy-efficient equipment, to reduce our carbon footprint and contribute to a cleaner, more sustainable future.As we continue to invest in cutting-edge technologies and expand our capabilities, we remain focused on providing our customers with the best solutions for their milling needs. Whether it’s a small batch of custom parts or a large-scale production run, we have the expertise and resources to deliver high-quality, precision-machined components that meet the most demanding requirements.In conclusion, milling in manufacturing is a crucial process for creating precision parts and components across a wide range of industries. At {Company Name}, we are proud to be at the forefront of this technology, offering our customers a comprehensive solution for their milling needs. With our advanced machining capabilities, commitment to quality, and dedication to sustainability, we are well-positioned to meet the evolving needs of the manufacturing industry and provide our customers with the highest standards of excellence.