- Home

- Components Of Cnc Milling Machine

Components of CNC Milling Machine: Wholesale Suppliers from China

Welcome to the world of advanced manufacturing with Dongguan K-Tek Machining Co., Ltd., a leading manufacturer, supplier, and factory based in China. We are proud to introduce our cutting-edge CNC milling machine, specifically designed to revolutionize the manufacturing industry.

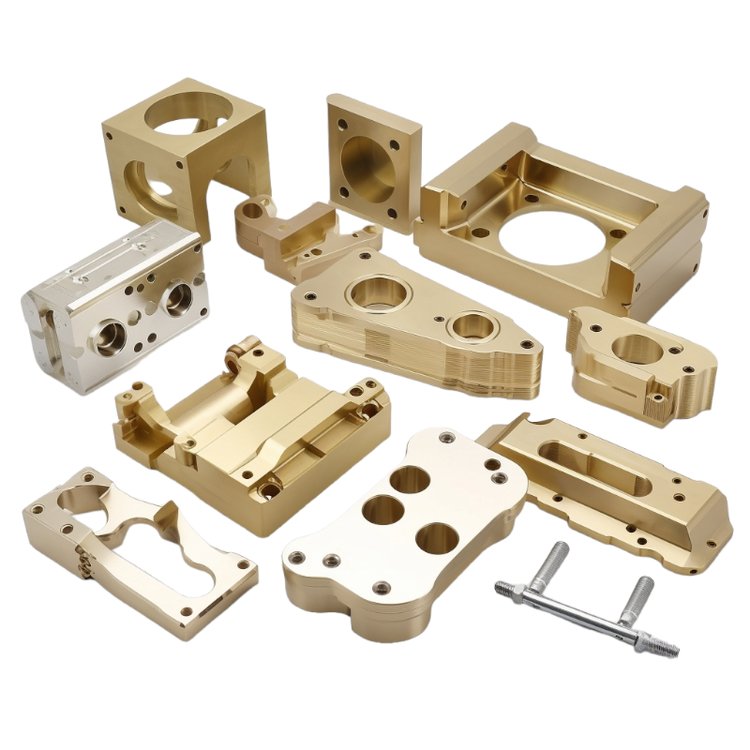

Featuring state-of-the-art technology, our CNC milling machine incorporates various components that guarantee precise and efficient machining. These components include a programmable control panel, high-speed spindle, cutting tools, tool holders, and a worktable. Together, these components work seamlessly to deliver exceptional accuracy and productivity.

With our CNC milling machine, you can effortlessly create complex three-dimensional shapes and intricate designs with unmatched precision. Our machine's versatility allows it to handle various materials, including metals, plastics, and composites.

Whether you are involved in automotive, aerospace, or any other manufacturing sector, our CNC milling machine offers great flexibility to meet your specific production requirements. Its user-friendly interface and intuitive software make it easy for operators of all skill levels to operate efficiently.

At Dongguan K-Tek Machining Co., Ltd., our commitment to quality and innovation drives us to deliver outstanding CNC milling machines that exceed customer expectations. Trust in our expertise to elevate your manufacturing processes and stay ahead of the competition.

K-Tek Machining Co., Ltd.

Company News

Related News

Copper processing service--focusing on a variety of small batch production

Discover top-quality copper processing service for small batch production at our factory. We offer efficient and reliable solutions for all your copper processing needs. Contact us now!

Plastic processing service--rich experience in processing parts

Plastic Processing Service - Unmatched Expertise in Part Manufacturing. As a leading factory, we offer top-notch plastic processing solutions for all your production needs. Contact us now!

K-Tek Overview Brochure

Discover the high-quality offerings of K-Tek, the leading factory specialized in manufacturing and delivering innovative and reliable products. Explore our K-Tek Overview Brochure now!

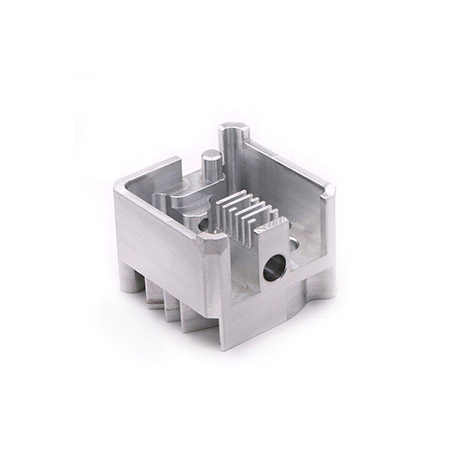

Machining of aluminum parts--more than 10 years of processing experience

Leading Factory with Over 10 Years of Experience in Aluminum Part Machining. Get High-Quality Products. Request a Quote Now!

CNC Turning Services-- engaged in multi-variety and small-batch mechanical parts

Looking for precision CNC turning services for multi-variety and small-batch mechanical parts? Look no further! Our factory specializes in delivering high-quality products.

Steel processing service--professional precision machine parts

Welcome to our factory offering professional steel processing services for precision machine parts. Get high-quality products for your business needs.

CNC Milling Services--engaged in the custom processing

Looking for CNC milling services? Look no further! Our factory specializes in custom processing. Get high-quality products with precision and efficiency.

Stainless steel processing service

Choose our superior stainless steel processing service factory for precision and quality. We offer a wide range of expert solutions. Contact us today!

Surface Treatment Services--meet the corrosion resistance, wear resistance

Discover our high-quality Surface Treatment Services, offering exceptional corrosion resistance and wear resistance. Trust in our factory expertise for top-notch results.

5 Axis CNC Machining Services

Offering top-notch {5 Axis CNC Machining Services}, our factory delivers precision and quality. Contact us for innovative solutions to your machining needs.

- Manufacturer of Components for CNC Milling Machine | OEM Supplier in China

- Reviews

- Related Videos

Introduction: Welcome to the world of CNC milling machines – the epitome of precision, efficiency, and versatility in modern manufacturing processes. When it comes to achieving complex shapes, intricate details, and consistent results, CNC milling machines are the ultimate solution. In this introduction, we will explore the various components of a CNC milling machine and how they work together to revolutionize your manufacturing capabilities. First and foremost, the heart of any CNC milling machine is its control system. This sophisticated computerized system enables precise and automated control over the entire milling process. It allows operators to program the machine with detailed instructions, resulting in unmatched accuracy and repeatability. Next, let's talk about the spindle, the powerhouse of a CNC milling machine. The spindle is responsible for rotating the cutting tool, such as an end mill or drill bit, at high speeds. With varying speed options, the spindle enables the machine to adapt to different materials and cutting requirements, ensuring optimal performance in every operation. Another vital component is the cutting tool itself. CNC milling machines employ a vast array of cutting tools, each designed for specific tasks. From roughing to finishing operations, these high-quality tools ensure precise removal of material, creating the desired shape with utmost efficiency. Of course, we cannot overlook the importance of the worktable – the platform on which the workpiece is securely held during the milling process. The worktable, usually adjustable in multiple axes, allows for accurate movement and positioning, ensuring seamless machining operations. Lastly, the machine frame provides stability and rigidity to the CNC milling machine. Constructed from high-quality materials, the frame ensures minimized vibration and enhanced accuracy, vital for achieving excellent results. In conclusion, CNC milling machines consist of various crucial components working seamlessly together to bring your manufacturing capabilities to new heights. With precision control, powerful spindles, versatile cutting tools, adjustable worktables, and sturdy machine frames, these machines redefine what is possible in modern manufacturing. Explore the world of CNC milling machines and witness the transformation in your production processes.

The CNC milling machine is a versatile tool that offers a range of features. It consists of various components that work together to deliver precision and efficiency. The sturdy frame provides stability, while the spindle rotates the cutting tool with high speed and accuracy. The control panel allows for easy programming and monitoring of the machine's performance. The precision table ensures precise movement of the workpiece, resulting in accurate cuts. Additionally, the cooling system prevents overheating, prolonging the machine's lifespan. Overall, the components of this CNC milling machine contribute to its impressive performance and make it a reliable tool for various applications.

The CNC milling machine is a robust system that provides efficient and accurate machining capabilities. Its components are designed to withstand high forces and ensure precise movement during the milling process. The machine includes a powerful spindle that rotates the cutting tool at high speeds, allowing for fast and precise material removal. The bed and table provide a stable platform for workpieces, guaranteeing accuracy and repeatability. The control panel and software allow for easy programming and customization of machining operations, making it suitable for a variety of applications. Overall, the CNC milling machine's well-built components make it a reliable and versatile tool for any machining needs.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours