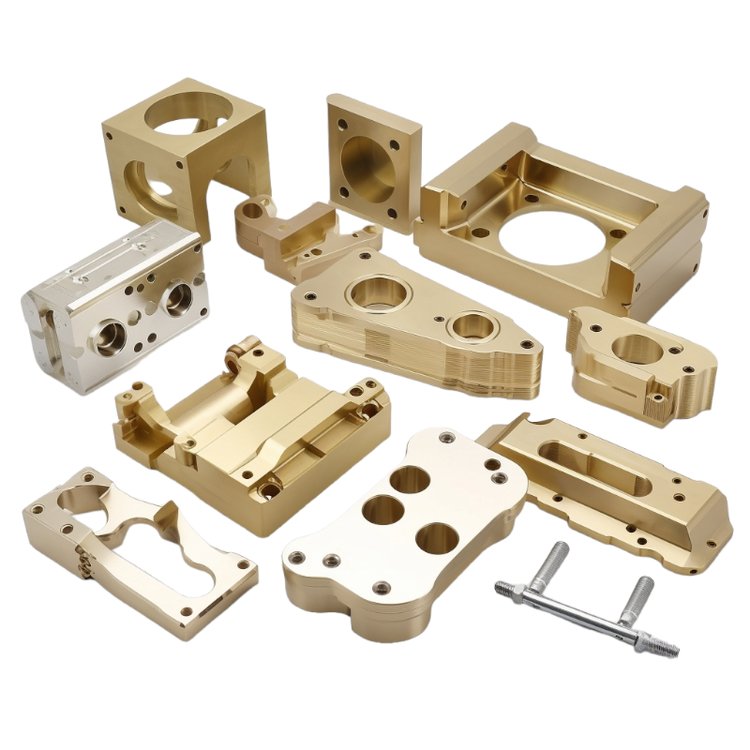

High-quality Precision Turned Parts for CNC Machining

By:Admin

Founded in 2005, Precision CNC Turned Parts has built a strong reputation for excellence in the manufacturing of precision components. With state-of-the-art facilities and a team of highly skilled engineers and technicians, the company has established itself as a trusted partner for companies seeking high-quality, reliable components for their products.

The expansion of Precision CNC Turned Parts' operations comes in response to the increasing demand for its products and the company's commitment to providing innovative solutions to its customers. By investing in new technologies and expanding its capabilities, the company aims to further solidify its position as a leader in the industry.

With a focus on continuous improvement and customer satisfaction, Precision CNC Turned Parts is dedicated to meeting and exceeding the expectations of its customers. By offering a comprehensive range of precision components, the company is able to provide custom solutions to meet the unique needs of each customer, ensuring that their products perform to the highest standards.

In addition to its dedication to excellence in manufacturing, Precision CNC Turned Parts is also committed to sustainable and responsible practices. The company adheres to strict environmental and quality standards, ensuring that its operations have a minimal impact on the environment while delivering products of the highest quality.

One of the key factors driving the expansion of Precision CNC Turned Parts is the company's ability to adapt to the evolving needs of the industries it serves. By staying ahead of the curve and investing in cutting-edge technology, the company is able to offer innovative solutions that meet the demands of modern manufacturing.

"We are excited to announce the expansion of our operations," said the CEO of Precision CNC Turned Parts. "This is an important milestone for our company, and it reflects our ongoing commitment to meeting the needs of our customers. By expanding our capabilities, we are better positioned to serve a wider range of industries and provide the high-quality precision components they require."

The expansion of Precision CNC Turned Parts' operations will include the addition of new machinery and equipment, as well as the hiring of additional staff to support the increased capacity. The company expects that these developments will not only allow for greater production capabilities but also provide opportunities for continued innovation and growth.

As Precision CNC Turned Parts continues to expand its operations, the company remains focused on maintaining the highest standards of quality and customer service. By providing reliable, innovative solutions to its customers, the company is well-positioned to continue its success in the precision components industry.

With a strong foundation of expertise, a commitment to innovation, and a dedication to customer satisfaction, Precision CNC Turned Parts is poised for continued growth and success in the years to come. The company's expansion is a testament to its ongoing dedication to excellence and its ability to provide the precision components that its customers rely on.

Company News & Blog

Affordable CNC Machining Services for Aluminum Materials

Cheap Aluminum CNC Technology Revolutionizes the Manufacturing IndustryAs technology continues to advance, the manufacturing industry is constantly being introduced to new and improved methods for production. One such revolutionary technology that has been making waves in the industry is the use of cheap aluminum CNC machining. This innovative process has quickly gained popularity due to its ability to produce high-quality products at an affordable cost.Cheap Aluminum CNC, also known as Computer Numerical Control, is a cutting-edge technology that allows for the automated control of machining tools such as lathes, mills, routers, and grinders. This precise and efficient method of manufacturing has completely transformed the way products are made, and has led to a significant increase in productivity and a decrease in production costs.The introduction of cheap aluminum CNC technology has been a game-changer for many businesses, particularly small and medium-sized enterprises that previously struggled to keep up with larger companies in terms of manufacturing capabilities. By utilizing this advanced technology, businesses are able to produce complex and intricate aluminum parts and components with ease, and at a fraction of the cost of traditional manufacturing methods.One company that has been at the forefront of this technological revolution is {}. With a strong focus on innovation and cutting-edge manufacturing processes, {} has been a leader in the development and implementation of cheap aluminum CNC technology. By investing in state-of-the-art equipment and employing highly skilled professionals, {} has been able to offer its clients superior quality products at competitive prices.The benefits of cheap aluminum CNC machining are numerous. Firstly, the ability to produce high-precision components with minimal human intervention has significantly reduced the risk of errors and defects in the manufacturing process. This has led to a higher level of consistency and quality in the products produced using this technology.Additionally, the speed and efficiency of cheap aluminum CNC machining have allowed businesses to significantly reduce lead times and meet tight production deadlines. This has been a game-changer for many industries, particularly those that require quick turnaround times for their products.Furthermore, the cost-effectiveness of cheap aluminum CNC machining has made it an attractive option for businesses looking to optimize their manufacturing processes. By reducing labor costs and material wastage, businesses can increase their profitability and gain a competitive edge in the market.In addition to the financial benefits, cheap aluminum CNC machining also has a positive impact on the environment. The efficient use of materials and reduced energy consumption associated with this technology helps to minimize the carbon footprint of manufacturing processes, making it a more sustainable option for businesses.As the demand for high-quality products at affordable prices continues to grow, the use of cheap aluminum CNC machining is expected to become increasingly prevalent in the manufacturing industry. With its ability to revolutionize the way products are made, this technology is set to play a key role in shaping the future of manufacturing.In conclusion, the introduction of cheap aluminum CNC technology has had a profound impact on the manufacturing industry. With its ability to produce high-quality products at a fraction of the cost of traditional methods, this innovative technology has paved the way for businesses to increase efficiency, reduce lead times, and improve overall productivity. As the industry continues to embrace this advanced manufacturing process, the benefits of cheap aluminum CNC machining are poised to have a lasting impact on the way products are made.

High-Quality Milled Metal Parts for Various Applications

Milled Metal Parts is a leading provider of high-quality metal components for a wide range of industries. With their state-of-the-art manufacturing facility and expert team of engineers, they are able to produce precision machined parts that meet the strictest industry standards. Their commitment to quality and customer satisfaction has made them a trusted partner for many companies around the world.The company specializes in the production of milled metal parts for a variety of applications, including automotive, aerospace, medical, and defense. Their extensive experience in working with different materials, such as aluminum, steel, and titanium, allows them to deliver components that are not only durable and reliable but also cost-effective.One of the key factors that sets Milled Metal Parts apart from its competitors is its advanced machining capabilities. They utilize the latest CNC milling technology to produce complex parts with tight tolerances and intricate geometries. This allows them to cater to the unique requirements of each customer and deliver custom solutions that meet their exact specifications.In addition to their machining expertise, Milled Metal Parts also offers a range of value-added services, including finishing, assembly, and quality inspection. This enables them to provide a complete turnkey solution for their customers, eliminating the need for them to work with multiple suppliers and ensuring seamless integration of the final product.Furthermore, the company is committed to upholding the highest standards of quality and safety in all aspects of its operations. They are certified to ISO 9001 and AS9100 standards, which demonstrates their dedication to continuous improvement and customer satisfaction. Additionally, their manufacturing processes comply with all relevant industry regulations and environmental standards, ensuring sustainable and responsible manufacturing practices.Recently, Milled Metal Parts has made significant investments in new technologies and equipment to further enhance their capabilities. This includes the acquisition of advanced multi-axis milling machines and the implementation of cutting-edge software for design and simulation. These investments have not only improved the company's productivity and efficiency but also expanded its capacity to take on larger and more complex projects.As a result of these investments, Milled Metal Parts has been able to strengthen its position as a preferred supplier for critical components in high-tech industries. Their ability to deliver precision parts with quick turnaround times has earned them a reputation for reliability and responsiveness, making them the go-to partner for many companies with strict production schedules and demanding quality requirements.Looking ahead, Milled Metal Parts is poised to capitalize on the growing demand for high-quality milled metal parts in the global market. With their unwavering commitment to excellence and their continuous pursuit of innovation, they are well-positioned to meet the evolving needs of their customers and anticipate new opportunities in the industry.In conclusion, Milled Metal Parts is a trusted provider of precision machined components, known for its advanced capabilities, commitment to quality, and dedication to customer satisfaction. With its strong track record and ongoing investments in technology and infrastructure, the company is well-positioned to maintain its leadership in the industry and continue serving as a valuable partner for companies seeking reliable and high-quality metal parts.

Quality CNC Machine Parts for Manufacturing Needs

The manufacturing industry is constantly evolving with new technologies and innovative processes, and one company at the forefront of this transformation is {CNC Machine Parts Manufacturer}. With their state-of-the-art facilities and commitment to delivering high-quality products, {CNC Machine Parts Manufacturer} has established itself as a leading provider of precision machined parts for a wide range of industries.Founded in 2005, {CNC Machine Parts Manufacturer} has quickly grown to become a trusted name in the manufacturing sector. Their focus on precision engineering and advanced manufacturing techniques has enabled them to meet the diverse needs of their customers, from aerospace and automotive to medical and defense industries. Thanks to their investment in cutting-edge equipment and a team of skilled engineers, {CNC Machine Parts Manufacturer} has earned a reputation for delivering top-notch products that meet the highest standards of quality and performance.One of the key factors that sets {CNC Machine Parts Manufacturer} apart from its competitors is their commitment to innovation. They are constantly exploring new technologies and processes to improve their manufacturing capabilities and deliver superior products to their customers. This dedication to staying ahead of the curve has enabled {CNC Machine Parts Manufacturer} to remain at the forefront of the industry, providing solutions that meet the evolving demands of modern manufacturing.In addition to their focus on innovation, {CNC Machine Parts Manufacturer} is also dedicated to providing exceptional customer service. They work closely with their clients to understand their specific needs and ensure that they receive the best possible solutions to meet their requirements. This customer-centric approach has led to strong, long-lasting relationships with many of their clients, who rely on {CNC Machine Parts Manufacturer} for high-quality, reliable machined parts.Despite the challenges posed by the global pandemic, {CNC Machine Parts Manufacturer} has continued to thrive and expand its operations. Their investment in advanced manufacturing technologies has allowed them to adapt to the changing landscape of the industry and continue to meet the needs of their customers. By staying true to their core values of excellence, innovation, and customer service, {CNC Machine Parts Manufacturer} has solidified its position as a leader in the manufacturing sector.Looking ahead, {CNC Machine Parts Manufacturer} is poised for further growth and success. They are constantly exploring new opportunities to expand their capabilities and reach new markets, both domestically and internationally. With a strong commitment to quality, innovation, and customer satisfaction, {CNC Machine Parts Manufacturer} is well-positioned to continue leading the way in the manufacturing industry for years to come.In conclusion, {CNC Machine Parts Manufacturer} is a company that has demonstrated its ability to thrive in a rapidly changing industry. With a focus on precision engineering, innovation, and customer service, they have established themselves as a trusted provider of high-quality machined parts. As they continue to grow and expand their operations, {CNC Machine Parts Manufacturer} is set to remain a key player in the manufacturing sector, providing solutions that meet the evolving needs of modern industry.

High-Quality Stainless Steel Turned Parts for Your Manufacturing Needs

Stainless Steel Turned Parts Invests in New Technology to Enhance Manufacturing CapabilitiesStainless Steel Turned Parts, a leading manufacturer of precision components, has recently announced a significant investment in new technology to enhance its manufacturing capabilities. The company, known for its expertise in producing high-quality turned parts for various industries, is committed to staying at the forefront of technological advancements to better serve its customers.With over 20 years of experience in the industry, Stainless Steel Turned Parts has established itself as a reliable and innovative supplier of precision components. The company is proud to offer a wide range of services, including CNC turning, milling, grinding, and assembly, all performed to the highest standards of quality and precision.In an increasingly competitive market, staying ahead of the curve is essential for any manufacturing company. This is why Stainless Steel Turned Parts has made the decision to invest in the latest technology to further improve its production processes. By upgrading its machinery and equipment, the company aims to increase efficiency, reduce lead times, and maintain its reputation for delivering superior products.One of the key areas of investment for Stainless Steel Turned Parts is in the expansion of its CNC machining capabilities. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computerized controls and automated machinery to produce parts with a high degree of accuracy and consistency. By adding new CNC machines to its lineup, the company will be able to handle a wider range of projects and meet the growing demand for complex, tight-tolerance components.In addition to upgrading its machining capabilities, Stainless Steel Turned Parts is also investing in advanced inspection and quality control systems. The company understands the importance of delivering parts that meet or exceed customer specifications, and the new inspection equipment will ensure that every component that leaves the facility is thoroughly checked for accuracy and quality.Furthermore, the company is also expanding its capacity for producing turned parts from stainless steel. With the increasing demand for stainless steel components across various industries, Stainless Steel Turned Parts is making strategic investments to meet this growing need. The company is committed to maintaining the highest standards of quality and precision, even as it scales up its production capabilities."We are excited to announce these investments in new technology, as they will significantly enhance our manufacturing capabilities and allow us to better serve our customers," said [Name], CEO of Stainless Steel Turned Parts. "We take pride in our ability to deliver precision components that meet the most stringent requirements, and these investments will further solidify our position as a trusted supplier in the industry."The decision to invest in new technology reflects Stainless Steel Turned Parts' dedication to continuous improvement and its commitment to meeting the evolving needs of its customers. By embracing the latest advancements in manufacturing, the company is positioning itself for long-term success and growth in an increasingly competitive market.As the company prepares for the implementation of the new technology, customers can expect to benefit from improved lead times, increased production capacity, and the same unwavering commitment to quality that Stainless Steel Turned Parts is known for. With these investments, the company is well-positioned to remain a leader in the production of precision stainless steel turned parts for years to come.

New High Precision Products: Commitment to Quality and Accuracy in Manufacturing

High Precision Products Launches Innovative Solution to Improve Industrial EfficiencyHigh Precision Products, a leading provider of advanced manufacturing technologies, has recently introduced a groundbreaking solution designed to revolutionize industrial efficiency. With a strong commitment to innovation and a deep understanding of the evolving needs of the manufacturing sector, High Precision Products has once again set a new standard for cutting-edge solutions.The company's newly launched product, which cannot be named due to proprietary reasons, is a result of extensive research and development aimed at addressing the challenges faced by modern industries. By leveraging the latest technological advancements and engineering expertise, High Precision Products has created a solution that promises to streamline operations, optimize production processes, and ultimately enhance overall efficiency.At the core of High Precision Products' innovative solution is a focus on precision engineering and advanced automation. The company's team of skilled engineers and technology experts have meticulously designed a product that offers unparalleled levels of accuracy, reliability, and performance. By integrating state-of-the-art sensors, control systems, and robotics, the solution is capable of delivering precise and consistent results, even in the most demanding industrial environments.In addition to its advanced technological features, High Precision Products' solution also boasts a user-friendly interface and intuitive controls, making it easy for operators to set up and manage. This user-centric design ensures that the solution can be seamlessly integrated into existing production workflows, without causing disruptions or requiring extensive training for staff.One of the key highlights of the new product is its versatility and adaptability across a wide range of applications. High Precision Products has ensured that its solution can be customized to meet the specific needs of different industries, whether it's automotive manufacturing, aerospace engineering, electronics production, or any other high-precision sector. This flexibility makes the product a valuable asset for a diverse array of businesses seeking to improve their operational efficiency and stay ahead of the competition.Furthermore, High Precision Products has placed a strong emphasis on the reliability and durability of its solution. Through rigorous testing and quality assurance processes, the company has ensured that the product meets the highest standards of performance and resilience, capable of withstanding the rigors of industrial operations over the long term. As a result, customers can trust in the dependability of High Precision Products' solution to deliver consistent results and contribute to their bottom-line success.The launch of this cutting-edge solution marks a significant milestone for High Precision Products, further solidifying its reputation as a trailblazer in the field of advanced manufacturing technologies. With a track record of delivering innovative solutions that surpass industry benchmarks, the company continues to demonstrate its commitment to driving progress and shaping the future of industrial production.As High Precision Products looks ahead, it remains dedicated to pushing the boundaries of what is possible in the realm of precision engineering and automation. By staying at the forefront of technological advancements and responding to the evolving needs of the market, the company is poised to continue leading the way in empowering industries with game-changing solutions.In conclusion, High Precision Products' latest product release has set a new standard for industrial efficiency, promising to deliver tangible benefits for businesses seeking to enhance their production processes and stay competitive in today's fast-paced market. With its unwavering dedication to innovation, precision, and performance, High Precision Products reaffirms its position as a trusted partner for businesses aiming to achieve excellence in manufacturing.

Achieving High Precision Machining Tolerances: What You Need to Know

High Precision Machining Tolerances: Setting the Standard for Precision EngineeringWhen it comes to precision engineering, nothing is more important than achieving high precision machining tolerances. These tolerances are crucial for ensuring the accuracy and quality of machined components, and they require cutting-edge technology and expertise to achieve. That's where [Company] comes in. [Company] is a leading provider of high precision machining services, specializing in meeting the most exacting tolerances for a wide range of industries, including aerospace, automotive, medical, and more. With a commitment to quality and precision, [Company] has become a trusted partner for organizations seeking to achieve the highest levels of accuracy in their machined components.One of the key factors that sets [Company] apart from its competitors is its state-of-the-art machining capabilities. The company utilizes the latest CNC machining technology and employs a team of highly skilled machinists to ensure that the most demanding tolerances can be met. This level of precision is critical for applications where even the smallest deviation can result in performance issues or failure.In addition to its advanced equipment and expertise, [Company] also places a strong emphasis on quality control. The company's quality management system is certified to ISO 9001 standards, demonstrating its commitment to delivering exceptional quality and reliability in every machined component. This dedication to quality has earned [Company] a solid reputation as a reliable partner for organizations with stringent quality requirements.One of the industries that [Company] serves is the aerospace industry, where precision and reliability are absolutely critical. Machined components for aerospace applications must adhere to extremely tight tolerances to ensure that they can withstand the rigors of flight and perform flawlessly in demanding environments. With its advanced machining capabilities and commitment to quality, [Company] has become a trusted supplier for aerospace manufacturers, delivering precision-engineered components that meet or exceed the industry's exacting standards.Another industry where high precision machining tolerances are essential is medical devices. Components for medical devices must meet very strict specifications to ensure their safety and efficacy. [Company] has the expertise and technology to produce complex, high-precision components for medical devices, helping its customers bring life-saving and life-improving technologies to market.In the automotive industry, [Company] plays a critical role in producing precision components for a wide range of applications, from performance racing to safety-critical systems. The company's ability to meet tight tolerances and deliver consistently high-quality products has made it a preferred supplier for automotive manufacturers and suppliers.Overall, [Company] is dedicated to pushing the boundaries of precision engineering. By investing in the latest technology, employing a highly skilled workforce, and maintaining a relentless focus on quality, the company has positioned itself as a leader in the high precision machining industry. Its ability to meet the most demanding tolerances has made it a trusted partner for organizations across a wide range of industries, and its commitment to excellence ensures that it will continue to set the standard for precision engineering in the years to come.

Aluminum CNC Machining: Custom Services for Precise Metal Fabrication

Custom Aluminum CNC, a leading manufacturer in the industry, is revolutionizing the world of aluminum fabrication with their state-of-the-art techniques and cutting-edge technology. With a focus on precision, quality, and innovation, the company has established itself as a trusted partner for businesses seeking custom aluminum parts and components.The company's commitment to excellence is evident in their dedication to using the latest CNC technology to produce high-quality aluminum products. CNC, or Computer Numerical Control, allows for precise and efficient machining of aluminum parts, ensuring that each component meets the strictest quality standards. This innovative approach to manufacturing has enabled Custom Aluminum CNC to deliver custom solutions to a wide range of industries, including aerospace, automotive, electronics, and more.Furthermore, Custom Aluminum CNC's team of highly skilled engineers and technicians are experts in working with a variety of aluminum alloys, including 6061, 7075, and 2024. This expertise allows the company to create custom aluminum parts with exceptional strength, durability, and performance, meeting the unique specifications and requirements of each customer.In addition to their advanced CNC capabilities, Custom Aluminum CNC also offers a range of value-added services, including finishing, assembly, and packaging. This full-service approach ensures that customers receive a complete solution for their aluminum fabrication needs, streamlining their supply chain and reducing costs.One of the key differentiators for Custom Aluminum CNC is their commitment to environmental sustainability. The company has implemented eco-friendly practices throughout their manufacturing process, including the use of recycled aluminum and energy-efficient production methods. This dedication to sustainability not only benefits the environment but also allows the company to offer eco-friendly solutions to their customers, aligning with the growing demand for sustainable manufacturing practices.Moreover, Custom Aluminum CNC's dedication to quality and customer satisfaction has earned them a reputation as a trusted and reliable partner in the industry. The company takes pride in their ability to collaborate with customers to design and manufacture custom aluminum parts that meet their specific needs, ensuring that every project is a success.As the demand for custom aluminum parts continues to grow, Custom Aluminum CNC is well-positioned to meet the needs of businesses seeking high-quality, precision-engineered components. With their advanced CNC technology, expertise in aluminum alloys, and commitment to sustainability, the company is poised to remain a leader in the industry for years to come.In conclusion, Custom Aluminum CNC is at the forefront of revolutionizing the world of aluminum fabrication with their innovative approach to manufacturing. Through their advanced CNC technology, expertise in aluminum alloys, and commitment to sustainability, the company continues to set the bar for excellence in the industry. Businesses seeking custom aluminum parts can trust Custom Aluminum CNC to deliver precision, quality, and innovation in every project.

Discover the Latest in High Precision Products for Your Needs

High Precision Products Company, a leading manufacturer in the field of precision engineering, has recently announced a significant achievement in its ongoing commitment to innovation and technological advancement. The company, which specializes in the production of high-quality, precision components for a diverse range of industries, has successfully developed a groundbreaking new product that is set to revolutionize the way in which precision engineering is approached.With a wealth of experience and expertise in the field of precision engineering, High Precision Products Company has long been recognized as a pioneer in the industry. The company's dedication to research and development has consistently resulted in the creation of cutting-edge solutions that have helped to drive innovation and progress within the field.The latest breakthrough from High Precision Products Company comes in the form of a new, state-of-the-art component that is designed to offer unmatched levels of accuracy, reliability, and performance. Building on the company's existing portfolio of precision-engineered products, this new development represents a significant leap forward in the capabilities of precision engineering, and is expected to have a transformative impact across a wide range of industries.Speaking about the new product, the CEO of High Precision Products Company, stated, "We are incredibly proud to announce the development of this groundbreaking new component. Our team has worked tirelessly to push the boundaries of what is possible within the field of precision engineering, and we believe that this new product is a testament to our ongoing commitment to innovation and excellence. We are confident that this new development will set a new standard for precision engineering, and we are excited to see the impact that it will have across various industries."The innovative new product from High Precision Products Company has been carefully engineered to offer unparalleled levels of precision and performance. Utilizing the very latest in cutting-edge technology and manufacturing techniques, the component has been designed to meet the exacting standards of the most demanding applications, and is set to deliver exceptional results in even the most challenging of environments.In addition to its impressive technical capabilities, the new component also offers a range of practical benefits. Its advanced design and construction ensure that it is highly reliable and durable, while its streamlined form factor and lightweight construction make it easy to integrate into a wide variety of systems and applications. These features combine to make the new product from High Precision Products Company an incredibly versatile and adaptable solution for a diverse range of needs.Furthermore, the development of this new component underscores High Precision Products Company's ongoing commitment to providing its customers with the very best in precision engineering solutions. By continuously pushing the boundaries of what is possible within the field, the company is able to offer its customers access to the most advanced and innovative products available, enabling them to stay at the cutting-edge of their respective industries.Looking towards the future, High Precision Products Company has expressed its intention to further build on this success by continuing to invest in research and development, and by seeking out new opportunities to drive innovation and progress. The company remains firmly dedicated to its mission of pushing the boundaries of precision engineering, and is committed to developing new solutions that will help to shape the future of the industry.In conclusion, the recent announcement from High Precision Products Company regarding the development of a groundbreaking new precision-engineered component represents a significant milestone in the company's ongoing commitment to innovation and excellence. With its advanced design, exceptional performance, and practical benefits, the new product is set to have a transformative impact across a diverse range of industries. As High Precision Products Company looks towards the future, it remains dedicated to driving further progress within the field of precision engineering, and to continuously setting new standards of excellence.

Top 5 Tips for Effective Acrylic Machining

Acrylic Machining- A Leader in Precision ManufacturingAcrylic Machining is a renowned company specializing in precision machining of acrylic and plastic components for a wide range of industries. With state-of-the-art equipment and highly skilled technicians, they have established themselves as a leading provider of custom acrylic machining solutions.The company has a rich history dating back to over two decades, during which they have continually evolved and expanded their capabilities to meet the growing demands of their clients. Acrylic Machining prides itself on its ability to deliver high-quality, precise components with quick turn-around times, making them a go-to partner for businesses looking for reliable manufacturing solutions.One of the key factors that sets Acrylic Machining apart from its competitors is its commitment to utilizing advanced technology in their machining processes. The company has made significant investments in state-of-the-art CNC machines, laser cutting equipment, and 3D printing technology, allowing them to produce complex and intricate components with unparalleled accuracy.Additionally, Acrylic Machining offers a wide range of services, including precision CNC milling and turning, laser cutting and engraving, and vacuum forming. This comprehensive suite of capabilities enables the company to cater to a diverse array of industries, including aerospace, automotive, medical, and consumer goods, among others.Acrylic Machining's team of highly skilled technicians and engineers bring a wealth of knowledge and expertise to the table. Their deep understanding of materials and manufacturing processes allows them to work closely with clients to develop custom solutions that meet their specific needs and requirements. Whether it's a rapid prototype or a large-scale production run, the team at Acrylic Machining is dedicated to delivering exceptional results every time.The company prides itself on its ability to provide end-to-end solutions, from design and prototyping to full-scale production. This comprehensive approach not only streamlines the manufacturing process but also ensures that the final products meet the highest quality standards.In addition to their technological prowess, Acrylic Machining is also committed to environmental sustainability. The company actively seeks out eco-friendly materials and processes to minimize their environmental impact. By using recyclable materials and reducing waste, they are dedicated to doing their part in creating a more sustainable future.Acrylic Machining's commitment to quality, precision, and customer satisfaction has earned them a stellar reputation in the industry. Their track record of successfully delivering complex projects on time and within budget has solidified their position as a trusted partner for businesses looking for reliable manufacturing solutions.As the demand for precision machined acrylic components continues to grow, Acrylic Machining remains at the forefront of the industry, continually innovating and improving their processes to meet the evolving needs of their clients. With a focus on advanced technology, unmatched expertise, and a dedication to excellence, Acrylic Machining is poised to continue its success as a leader in precision manufacturing for years to come.

Expert CNC Aluminum Fabrication Services for High-Quality Results

CNC Aluminum Fabrication: A Revolutionizing Manufacturing ProcessIn the fast-paced world of manufacturing, the need for precision and efficiency has become paramount. As industries continue to evolve and demand quality products at a rapid pace, the use of advanced technologies has become increasingly essential. One such technology that has revolutionized the manufacturing industry is CNC Aluminum Fabrication. This cutting-edge process has become the go-to method for producing high-quality aluminum parts and components with unparalleled precision and speed.CNC Aluminum Fabrication, also known as Computer Numerical Control Aluminum Fabrication, involves the use of computer-controlled machines to accurately shape and cut aluminum materials into desired shapes and sizes. This process allows for immense flexibility in design and production, making it ideal for a wide range of applications across various industries.The process begins with the creation of a digital 3D model or CAD drawing of the desired part or component. This digital design is then fed into the CNC machine, which uses precise mathematical algorithms to control the movements of the cutting tools. This level of precision ensures that the final product is an exact replica of the digital design, with minimal margin for error.One company that has mastered the art of CNC Aluminum Fabrication is {}. With a strong commitment to innovation and excellence, {} has established itself as a leader in the manufacturing industry. Through the use of state-of-the-art CNC machines and a team of highly skilled engineers and technicians, the company has been able to deliver unparalleled precision and quality in their aluminum fabrication processes.{} has developed a reputation for providing customized solutions to meet the unique needs of their clients. Whether it's producing complex aerospace components, automotive parts, or architectural elements, the company has the expertise and technology to turn any design concept into a reality. Their dedication to quality and efficiency has earned them the trust and confidence of their clients, making them a preferred choice for CNC Aluminum Fabrication.The benefits of CNC Aluminum Fabrication are numerous and have had a profound impact on the manufacturing industry. One of the key advantages is the ability to produce complex designs with intricate details that would be impossible to achieve through traditional manufacturing methods. This level of precision and customization has opened up new possibilities in product development and has allowed companies to create innovative and groundbreaking designs.Furthermore, CNC Aluminum Fabrication offers remarkable efficiency in production. The automation of the manufacturing process reduces the need for manual labor, resulting in faster production times and lower production costs. This not only benefits manufacturers by increasing their productivity but also allows them to meet tight deadlines and deliver products to market more rapidly.Another significant advantage of CNC Aluminum Fabrication is the consistency and repeatability it provides. Once a digital design is programmed into the CNC machine, the fabrication process can be replicated with the same level of precision and accuracy every time. This ensures that each part or component produced is uniform in quality and meets the specified standards, thus reducing the likelihood of defects or errors in the final product.With the continuous advancements in manufacturing technology, CNC Aluminum Fabrication is poised to play an even more significant role in the industry's future. As the demand for high-quality, precision-engineered components continues to rise, the need for advanced fabrication processes such as CNC will only grow. This will not only lead to greater innovation and efficiency but will also enable companies to push the boundaries of what is possible in manufacturing.In conclusion, CNC Aluminum Fabrication has become a game-changer in the manufacturing industry, offering unmatched precision, efficiency, and customization. Companies like {} have demonstrated the immense potential of this technology and its ability to meet the evolving demands of modern manufacturing. As industries continue to evolve, it's clear that CNC Aluminum Fabrication will remain at the forefront of innovation, driving the development of high-quality products and revolutionizing the way we approach manufacturing.