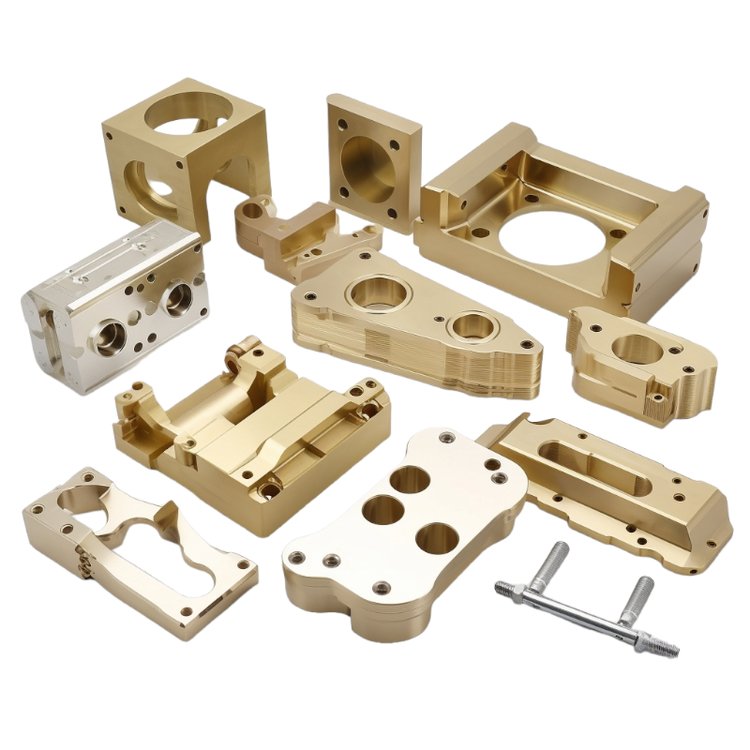

High-Quality CNC Machining Service in China for Your Manufacturing Needs

By:Admin

China has long been known for its strong manufacturing industry, and the country's CNC machining service sector is no exception. With the increasing demand for high-precision parts and components in various industries, China's CNC machining service providers have been continuously expanding and innovating to meet the market's needs.

One of the leading CNC machining service providers in China, [], has been at the forefront of this industry development. With its state-of-the-art facilities and cutting-edge technology, the company has been delivering high-quality precision machining solutions to its global clientele.

Established in [], [] has quickly become a trusted partner for businesses in various sectors, including aerospace, automotive, medical, and telecommunications. The company's commitment to quality, reliability, and continuous improvement has helped it build a solid reputation in the industry.

One of the key factors driving the growth of China's CNC machining service industry is the increasing demand for custom-made components in various high-tech industries. As companies strive to stay ahead of the competition by introducing new products and technologies, the need for precise and reliable parts has become more critical than ever.

With its extensive experience and expertise, [] has been able to meet the complex requirements of its clients, providing them with tailored solutions that meet their specific industry needs. The company's dedication to research and development has enabled it to stay ahead of the curve, offering advanced machining techniques and materials to its customers.

In addition to the growing demand for custom precision parts, the rapid development of the electric vehicle (EV) industry has also played a significant role in driving the expansion of China's CNC machining service sector. The increasing adoption of EVs has created a surge in the demand for high-precision components, such as battery housings, motor parts, and charging infrastructure.

As a result, CNC machining service providers like [] have been heavily investing in advanced equipment and technologies to meet the specific requirements of the EV industry. By offering specialized machining capabilities for EV-related components, the company has positioned itself as a go-to partner for EV manufacturers looking for reliable and high-quality machining solutions.

Moreover, the global trend towards automation and robotics has further fueled the growth of China's CNC machining service industry. As more industries automate their production processes, the demand for precision-machined parts for robots and automation equipment has continued to increase.

Recognizing this market opportunity, [] has been actively expanding its capabilities to serve the evolving needs of the automation industry. The company's investment in advanced automation technologies has allowed it to offer a wide range of precision-machined components for robotic arms, motion control systems, and other automation equipment.

The COVID-19 pandemic has also accelerated the adoption of automation and robotics in various industries, as businesses seek to minimize human interaction and improve production efficiency. As a result, the demand for CNC machining services that can support the automation industry has remained robust, driving further growth in the sector.

Looking ahead, China's CNC machining service industry is poised for continued expansion and innovation, driven by the increasing demand for high-precision parts in key industries such as aerospace, automotive, EV, and automation. With companies like [] leading the way with their advanced capabilities and dedication to excellence, China's CNC machining service sector is well-positioned to remain a key player in the global manufacturing landscape.

Company News & Blog

Stainless Steel Machining: High Precision CNC Services

CNC Stainless Steel Machining at the Forefront of Advanced ManufacturingThe manufacturing industry has seen significant advancements in recent years, particularly with the rise of CNC stainless steel machining. This innovative technology has revolutionized the way stainless steel parts and components are produced, offering a level of precision and efficiency that was previously unimaginable.One company that has been at the forefront of this trend is {}. Their state-of-the-art facility is equipped with the latest CNC machining technology, allowing them to meet the growing demand for high-quality stainless steel components across a wide range of industries.The use of CNC machining has allowed {} to streamline their production processes, reducing lead times and increasing overall efficiency. This has enabled them to deliver consistently high-quality products to their customers, while also remaining competitive in the global marketplace.One of the key advantages of CNC stainless steel machining is its ability to produce complex and intricate parts with a level of precision that is simply unattainable with traditional manufacturing methods. This has opened up new possibilities for design and engineering, allowing for the creation of innovative and cutting-edge products across various industries.In addition to its precision, CNC machining also offers a high level of repeatability, ensuring that every part produced is identical to the last. This level of consistency is crucial for industries such as aerospace, defense, and medical, where strict quality control measures are essential.The use of CNC machining has also had a significant impact on the cost of stainless steel parts production. By automating much of the manufacturing process, {} has been able to reduce labor costs and minimize material waste, resulting in cost savings that are passed on to their customers.Furthermore, the advanced technology used in CNC machining has allowed {} to take on increasingly complex and challenging projects, further expanding their capabilities and scope of services. This has positioned them as a leader in the industry, capable of delivering high-quality stainless steel components for a wide range of applications.In addition to their advanced machinery, {} prides itself on its team of highly skilled and experienced engineers and technicians, who are able to utilize the full potential of CNC machining to bring their customers' designs to life. This combination of cutting-edge technology and top-tier talent has set {} apart as a premier provider of CNC stainless steel machining services.As the demand for precision-engineered stainless steel parts continues to grow, {} remains committed to staying ahead of the curve and providing their customers with the highest quality products and services. With their continued investment in advanced technology and dedication to excellence, {} is well-positioned to meet the evolving needs of the manufacturing industry and lead the way in CNC stainless steel machining.In conclusion, the rise of CNC stainless steel machining has had a transformative impact on the manufacturing industry, offering unmatched precision, efficiency, and cost-effectiveness. With companies like {} leading the way, the future of advanced manufacturing looks bright, with innovative solutions and high-quality products driving progress and innovation.

High-Quality CNC Parts Manufactured in China

CNC Parts China is a leading manufacturer and supplier of high-quality CNC parts for various industries. The company has been in business for over 20 years and has gained a strong reputation for delivering precision-engineered components to customers around the world. Their extensive range of CNC parts includes precision machined components, custom CNC milling and turning parts, as well as a variety of other specialized components.The company is known for its state-of-the-art manufacturing facilities, which are equipped with the latest CNC machines and technology. This allows them to produce parts with extremely high precision and accuracy, meeting the strictest quality standards. Their team of highly skilled engineers and technicians are dedicated to producing top-quality CNC parts that meet the specific requirements of their customers.One of the company's core strengths is its ability to provide customized solutions for clients in a wide range of industries, including automotive, aerospace, electronics, and medical equipment. Whether it's a small batch of custom components or a large-scale production run, CNC Parts China has the capabilities to meet the unique needs of each customer.In addition to their commitment to quality and precision, CNC Parts China is also dedicated to providing excellent customer service. The company has a team of knowledgeable and experienced professionals who work closely with clients to understand their requirements and provide tailored solutions. From the initial design phase to the final delivery of the parts, customers can expect seamless communication and support every step of the way.To further enhance their capabilities and meet the growing demand for CNC parts, the company has recently expanded its manufacturing facilities and invested in new technology. This allows them to increase their production capacity and offer even faster turnaround times for their customers. Additionally, CNC Parts China is continuously investing in research and development to stay at the forefront of industry innovation and provide cutting-edge solutions to their clients.The company's commitment to quality, precision, and customer satisfaction has earned them a strong reputation in the industry. They have built long-term partnerships with many leading companies around the world, who rely on CNC Parts China for their CNC machining needs. Their dedication to excellence has also led to numerous certifications and accolades, further demonstrating their expertise and reliability as a CNC parts supplier.As CNC Parts China continues to grow and expand its capabilities, they remain committed to delivering the highest quality CNC parts and exceptional service to their customers. With their advanced manufacturing facilities, experienced team, and dedication to innovation, the company is well-positioned to meet the evolving needs of the industry and continue to be a trusted partner for clients seeking top-quality CNC parts.Overall, CNC Parts China stands out as a leading manufacturer and supplier of CNC parts, with a strong focus on precision, quality, and customer satisfaction. Their dedication to excellence and continuous investment in technology and innovation make them a reliable choice for companies seeking top-quality CNC parts for their projects.

CNC Lathe Machine Parts: Essential Components for Efficient Precision Machining

Title: Revolutionizing Precision Manufacturing with Advanced CNC Lathe Machine PartsIntroduction:In today's rapidly evolving manufacturing industry, technological advancements play a crucial role in enhancing efficiency and precision. One such revolutionizing development is the integration of innovative CNC lathe machine parts. With their state-of-the-art attributes and cutting-edge functionality, these components are revolutionizing precision manufacturing processes across various sectors.Company Overview:As a leading provider of CNC lathe machine parts, our company has established itself as an industry pioneer, continuously pushing the boundaries of innovation. We strive to deliver exceptional precision engineering solutions that cater to the diverse needs of our esteemed clientele. With a commitment to quality, reliability, and staying ahead of the curve, our products have garnered immense recognition and trust in the market.Body:1. Introduction to CNC Lathe Machine Parts:CNC (Computer Numerical Control) lathe machine parts have transformed traditional machining practices by offering unparalleled precision, efficiency, and flexibility. These parts are designed to fit into computer-controlled lathes, which enables automated and highly accurate machining operations. By utilizing advanced software and cutting-edge technology, CNC lathe machine parts have become indispensable tools in industries such as automotive, aerospace, electronics, and medical equipment manufacturing.2. Key Features and Benefits:a) Enhanced Precision: CNC lathe machine parts are equipped with advanced sensors and control systems, which ensure unprecedented accuracy, consistency, and repeatability. This level of precision results in superior product quality and reduced waste, making them ideal for intricate and critical components.b) Simplified Operations: With integrated computerized controls, CNC lathe machine parts provide user-friendly interfaces that require minimal manual intervention. The ability to automate complex machining processes significantly reduces human error, labor costs, and production time.c) Versatility and Flexibility: These components offer extensive customization options, allowing manufacturers to adapt their machining operations to a diverse range of materials, geometries, and specifications. This flexibility enables companies to fulfill customer demands efficiently, even for small production runs.d) Increased Efficiency: Through efficient cutting strategies and optimized tool paths, CNC lathe machine parts significantly improve productivity by reducing cycle times and maximizing machine utilization. This increased efficiency enables manufacturers to meet demanding deadlines and scale production seamlessly.e) Cost-Effectiveness: Although CNC lathe machine parts have a higher initial investment, their long-term cost-effectiveness cannot be overlooked. Their precision and efficiency lead to substantial material and time savings, reducing overall production costs and boosting profitability in the long run.3. Range of CNC Lathe Machine Parts:Our company offers an extensive range of CNC lathe machine parts that cater to various industry requirements. These parts include but are not limited to:a) Spindles and Chuck Systems: These critical components are responsible for holding and rotating the workpiece during machining operations. Our advanced spindles and chuck systems ensure stable and accurate positioning, contributing to the overall precision and quality of the finished products.b) Tool Holders and Accessories: Our tool holders are designed to securely hold cutting tools and optimize their performance. With excellent vibration dampening properties and quick-change systems, these accessories enhance machining stability and reduce tool changeover times.c) Control Systems and Software: We provide cutting-edge control systems and software that integrate seamlessly with CNC lathe machines. These systems offer an intuitive user interface, intelligent tool management, and advanced programming capabilities, enabling manufacturers to achieve precise and efficient machining.d) Cutting Tools: Our comprehensive range of cutting tools includes inserts, drills, and milling cutters designed for various materials and machining requirements. These high-performance tools ensure exceptional machining accuracy and prolong tool life, further optimizing production processes.4. Customer Success Stories: Highlighting success stories of our customers who have benefited from incorporating CNC lathe machine parts in their operations will depict the significant impact these components have had on their businesses. Case studies demonstrating increased productivity, improved quality, and higher cost-efficiency will add credibility to the news content.Conclusion:The integration of advanced CNC lathe machine parts has marked a significant paradigm shift in precision manufacturing. With their unrivaled precision, user-friendly interfaces, and versatility, these components are empowering manufacturers across industries to enhance their competitiveness and achieve outstanding results. As a leading provider of CNC lathe machine parts, our company continues to drive innovation and deliver exceptional solutions that redefine precision machining standards.

Premium Anodization Service: Exceptional Quality and Customization Offered

[Company Name] Introduces Anodization Service: Innovation Meets Durability[City, Date] - [Company Name], a leading provider of cutting-edge solutions, is pleased to announce the launch of its state-of-the-art anodization service. With a long-standing reputation for excellence in the industry, [Company Name] continues to push the boundaries of innovation by introducing this new offering.Anodization is a process that creates a protective oxide layer on the surface of metals, enhancing their durability, corrosion resistance, and aesthetics. [Company Name], known for its commitment to ensuring superior quality and customer satisfaction, aims to revolutionize the anodization process with its advanced technology and expertise.Through its anodization service, [Company Name] caters to a wide range of industries, including aerospace, automotive, electronics, and architecture. By leveraging their extensive experience and utilizing cutting-edge machinery, the company provides customers with an unmatched level of precision and customization.One of the key advantages of [Company Name]'s anodization service is the ability to offer a comprehensive range of colors and finishes. Whether clients require a sleek metallic appearance, vibrant colors, or a textured finish, [Company Name] can meet their exact specifications. This flexibility allows clients to enhance the visual appeal of their products while simultaneously providing them with increased durability.Furthermore, [Company Name]'s anodization process is environmentally friendly. By employing sustainable practices and utilizing eco-friendly materials, the company aims to minimize its carbon footprint and promote a greener future. This commitment to sustainability aligns with the broader industry shift towards eco-conscious manufacturing.The superior quality offered by [Company Name] is a result of their dedication to continuous improvement and adherence to stringent quality control measures. Each step of the anodization process is meticulously executed, ensuring that every product leaving [Company Name]'s facility meets the highest standards.To provide customers with added peace of mind, [Company Name] also offers a comprehensive warranty on its anodized products. This demonstrates the company's confidence in the durability and longevity of their solutions. Additionally, a highly skilled team of experts is always available to assist customers with any inquiries or technical support they may require.In celebration of the launch of their anodization service, [Company Name] is offering special incentives and discounts to new and existing clients for a limited time. This presents an excellent opportunity for businesses to experience the benefits of anodization while taking advantage of unprecedented cost savings.By introducing its anodization service, [Company Name] cements its position as an industry leader, continuously pushing the boundaries of innovation. The company's commitment to quality, sustainability, and customer satisfaction ensures that their anodized products will have a lasting impact on various industries.About [Company Name]:Established in [Year], [Company Name] has been a frontrunner in delivering cutting-edge solutions to a diverse range of industries. With a highly skilled team and state-of-the-art technology, the company continues to provide superior quality and customer service. By combining innovation, durability, and a commitment to sustainability, [Company Name] sets itself apart from its competitors.For more information about [Company Name]'s anodization service and to explore their comprehensive range of solutions, please visit their website [Website URL] or contact their customer service team at [Phone Number].

High-Quality Aluminum CNC Milling Services for Precision Parts

Aluminum CNC Mill: Precision Engineering for a Variety of IndustriesIn the world of precision engineering, the demand for high-quality aluminum CNC milling services is constantly on the rise. As industries continue to seek innovative solutions for their machining needs, the importance of finding a reliable and efficient CNC milling partner is more important than ever. This is where the expertise and capabilities of (company name) come into play. With a commitment to excellence and a dedication to delivering exceptional results, (company name) has solidified its position as a trusted leader in the field of aluminum CNC milling.At (company name), we understand the unique challenges and requirements of our clients, and we are proud to offer a comprehensive range of aluminum CNC milling services to meet their diverse needs. Our state-of-the-art facility is equipped with the latest CNC milling technology, allowing us to handle projects of all sizes and complexities with precision and efficiency. Whether it's a small prototype or a large-scale production run, our team of highly skilled engineers and machinists has the expertise and capabilities to deliver exceptional results.Our commitment to quality is evident in every aspect of our operations. From the initial consultation to the final product delivery, we ensure that every project is handled with the utmost care and attention to detail. Our rigorous quality control processes and strict adherence to industry standards guarantee that our clients receive the highest quality products that meet their exact specifications.In addition to our cutting-edge CNC milling capabilities, (company name) also offers a range of value-added services to further meet the needs of our clients. From design assistance to material selection, prototype development to full-scale production, we are dedicated to providing comprehensive solutions that exceed our clients' expectations. Our team is committed to working closely with our clients throughout every stage of the process to ensure that their unique requirements are met with precision and efficiency.One of the key factors that set (company name) apart from other CNC milling service providers is our unwavering commitment to customer satisfaction. We understand that each project is unique, and we are dedicated to providing personalized service that is tailored to the specific needs of our clients. Whether it's a tight deadline, complex specifications, or specific budget constraints, our team is dedicated to finding solutions that meet our clients' needs.Our commitment to excellence and dedication to delivering exceptional results has earned us the trust and loyalty of clients across a wide range of industries. From aerospace and automotive to medical device manufacturing and beyond, (company name) has a proven track record of delivering high-quality CNC-milled aluminum components that meet the most stringent requirements.As the demand for precision-engineered aluminum components continues to grow, (company name) remains at the forefront of the industry, continuously investing in the latest technology, expanding our capabilities, and refining our processes to ensure that we can meet the evolving needs of our clients.In conclusion, (company name) is proud to be a leading provider of aluminum CNC milling services, offering a comprehensive range of capabilities and a commitment to excellence that is unmatched in the industry. With a focus on precision, quality, and customer satisfaction, (company name) is the ideal partner for all your CNC milling needs. Contact us today to learn more about how we can help bring your precision engineering projects to life.

High-Quality Brass Fabrication Services for Custom Projects

Custom Metal Fabrication Company Excels in Brass FabricationWith a focus on precision, quality, and efficiency, Custom Metal Fabrication Company has established itself as a leader in the industry. Specializing in a wide range of metal fabrication services, the company has a proven track record of delivering exceptional products to its customers. Among its many specialties, brass fabrication stands out as one of the company's top offerings.Brass fabrication requires a high level of expertise and attention to detail, as brass is a unique metal that demands a skilled hand to work with. Custom Metal Fabrication Company has honed its brass fabrication techniques over the years, developing a reputation for excellence in this specialized field. From custom brass parts to intricate brass components, the company has the knowledge and capabilities to exceed its customers' expectations."We take great pride in our brass fabrication capabilities," says [Name], CEO of Custom Metal Fabrication Company. "Brass is a beautiful and versatile material, and we have mastered the art of working with it to create outstanding products for our clients."The company's brass fabrication process begins with a careful assessment of the customer's needs and specifications. From there, its team of skilled engineers and fabricators work closely with the client to develop a custom solution that meets their exact requirements. Using state-of-the-art equipment and cutting-edge techniques, the company is able to produce precision-crafted brass components with unmatched accuracy.Custom Metal Fabrication Company's dedication to quality is evident in every step of its brass fabrication process. From the initial design phase to the final inspection, the company's team is committed to upholding the highest standards of craftsmanship. This attention to detail ensures that each brass piece that leaves the facility is of the utmost quality, meeting or exceeding the customer's expectations.In addition to its technical expertise, Custom Metal Fabrication Company is also known for its exceptional customer service. The company believes in building strong, collaborative relationships with its clients, working closely with them throughout the fabrication process to ensure their complete satisfaction. This customer-centric approach has earned the company a loyal customer base and a reputation for reliability and integrity."Our customers are at the heart of everything we do," [Name] explains. "We go above and beyond to deliver the best possible service and products to them. Our goal is to not just meet, but exceed their expectations in every aspect."With its combination of technical prowess, superior craftsmanship, and unwavering commitment to customer satisfaction, Custom Metal Fabrication Company has solidified its position as a top provider of brass fabrication services. Whether the project calls for intricate brass components or larger-scale brass structures, the company has the expertise and capabilities to deliver outstanding results.Looking ahead, Custom Metal Fabrication Company is poised to continue its success in the brass fabrication market. The company remains dedicated to staying at the forefront of industry trends and advancements, ensuring that it can consistently provide its clients with the best possible solutions. As the demand for high-quality brass fabrication services continues to grow, Custom Metal Fabrication Company is well-positioned to meet and exceed the expectations of its customers.In conclusion, Custom Metal Fabrication Company's expertise in brass fabrication sets it apart as a leader in the industry. With its unwavering commitment to quality, precision, and customer satisfaction, the company has earned a well-deserved reputation for excellence. As it continues to expand its capabilities and services, Custom Metal Fabrication Company is poised to remain a top choice for brass fabrication needs.

High-Quality Custom Brass Sheet Cutting Services for Your Project

Custom Cut Brass Sheet Company (CCBSC) is a renowned manufacturer and supplier of high-quality brass sheets. Known for their precision and superior quality, CCBSC has been serving a diverse range of industries for many years. Their dedication to customer satisfaction and commitment to excellence has made them a trusted name in the metal manufacturing industry.CCBSC takes pride in their ability to provide custom cut brass sheets to meet the specific needs of their customers. Their state-of-the-art facilities and skilled team of professionals enable them to produce brass sheets in various thicknesses, sizes, and finishes. Whether their clients require brass sheets for architectural, industrial, or decorative purposes, CCBSC can deliver the perfect solution tailored to their exact specifications.In addition to custom cutting, CCBSC also offers a wide range of brass alloys to cater to different application needs. Their brass sheets are available in various grades, including C260, C280, and C360, each offering unique properties and characteristics. With their extensive knowledge and expertise in brass manufacturing, CCBSC can assist customers in choosing the right alloy for their specific requirements.One of the key advantages of partnering with CCBSC is their ability to provide quick turnaround times without compromising on quality. Their efficient production processes and strict quality control measures ensure that each brass sheet meets the highest standards before being delivered to the customer. This reliability and consistency have earned CCBSC a solid reputation in the industry, making them the go-to supplier for many businesses.Furthermore, CCBSC is committed to sustainability and environmentally friendly practices. They prioritize the use of recycled materials in their manufacturing processes and adhere to strict environmental regulations. Customers can be assured that by choosing CCBSC as their supplier, they are supporting a company that values eco-conscious production methods.Recently, CCBSC has introduced a new range of custom-cut brass sheets that offer enhanced durability and corrosion resistance. These sheets are designed to withstand harsh environmental conditions, making them ideal for outdoor applications such as marine and architectural projects. The new product line has already garnered positive feedback from clients who have experienced the superior performance of these brass sheets.In addition to their product innovation, CCBSC continues to invest in research and development to stay ahead of industry trends and technological advancements. By staying at the forefront of metal manufacturing, CCBSC ensures that their customers have access to the latest and most advanced brass sheet solutions available.CCBSC's commitment to excellence extends beyond their product offerings. Their customer service team is dedicated to providing personalized support and guidance to help clients find the best brass sheet solutions for their specific needs. Whether it's technical assistance, customization advice, or logistical support, CCBSC's knowledgeable staff is always ready to assist their customers every step of the way.As CCBSC continues to thrive in the competitive metal manufacturing market, their focus remains on delivering top-quality brass sheets and exceptional service to their clientele. Their dedication to innovation, sustainability, and customer satisfaction sets them apart as a leader in the industry. With a strong track record of success and a growing list of satisfied customers, CCBSC is poised to remain a trusted partner for businesses in need of custom-cut brass sheet solutions.

High-Quality CNC Machining Parts: Everything You Need to Know

Announces Expansion of Cnc Machining Parts Production Facility - , a leading manufacturer of precision machined parts and components, has announced plans to expand its CNC machining parts production facility. The expansion comes in response to increased demand for high-quality, custom CNC machined parts across a wide range of industries.The company's CNC machining capabilities are a crucial part of its overall manufacturing operations, allowing for the production of complex, precise parts that are used in a variety of applications, including aerospace, automotive, medical, and more. With the expansion of its CNC machining facility, will be able to better meet the needs of its customers and continue to deliver high-quality, reliable parts with quick turnaround times."We are excited to announce the expansion of our CNC machining parts production facility," said , at . "This investment will allow us to increase our capacity and capabilities, enabling us to better serve our customers and meet the growing demand for custom CNC machined parts."In addition to expanding its CNC machining facility, is also committed to investing in the latest technology and equipment to ensure that its parts meet the highest standards of quality and precision. The company has a team of highly skilled machinists and engineers who are dedicated to delivering top-notch parts that meet the exact specifications of each customer."We take great pride in our ability to create custom CNC machined parts that meet the unique needs of our customers," said . "Our team has the expertise and technology to produce parts with extremely tight tolerances and complex geometries, making us a trusted partner for precision machined components." offers a wide range of CNC machining services, including milling, turning, and grinding, as well as secondary operations such as deburring, anodizing, and assembly. The company is equipped to work with a variety of materials, including aluminum, steel, stainless steel, and titanium, and can accommodate both small and large production runs.As a company that is committed to continuous improvement, is dedicated to providing its customers with the highest level of service and quality. The expansion of its CNC machining facility is just one example of the company's ongoing efforts to enhance its capabilities and better serve its customers."We are always looking for ways to improve and grow as a company," said . "Expanding our CNC machining parts production facility is just one step in that direction, and we are excited to see the positive impact it will have on our ability to meet the needs of our customers."The expansion of 's CNC machining facility is expected to be completed within the next six months. In the meantime, the company remains fully operational and continues to fulfill orders for custom CNC machined parts.For more information about 's CNC machining services or to request a quote for custom parts, visit the company's website at www.companyname.com. The company looks forward to continuing to serve its customers with high-quality, precision machined parts and looks forward to the opportunities that the expanded facility will bring.

High-Quality CNC Milling Parts for Your Manufacturing Needs

{Company Name} is proud to announce the launch of their new CNC milling parts, which have been designed to revolutionize the manufacturing industry. With a commitment to precision engineering and innovation, {Company Name} has developed high-quality milling parts that will improve efficiency and productivity for a wide range of applications.CNC milling is a process that uses computer numerical control (CNC) technology to automate the cutting of metal and other solid materials. This process is essential in the production of parts and components for industries such as aerospace, automotive, and medical devices. {Company Name} has recognized the increasing demand for precise and reliable milling parts, and has responded by developing a cutting-edge product that meets the needs of modern manufacturing.One of the key features of {Company Name}'s CNC milling parts is their exceptional precision. These parts are manufactured with advanced CNC machines that are capable of producing complex shapes and geometries with a high degree of accuracy. This level of precision is essential for industries that require tight tolerances and exact measurements, ensuring that the final products meet the highest standards.In addition to precision, {Company Name}'s CNC milling parts are also known for their durability and reliability. The company uses only the highest quality materials and processes, ensuring that the parts can withstand the demands of heavy-duty applications. This reliability is essential for industries where downtime is not an option, as it minimizes the risk of equipment failure and ensures consistent production.Another important aspect of {Company Name}'s CNC milling parts is their versatility. The company offers a wide range of milling parts that can be customized to meet the specific needs of different industries. Whether it's a complex aerospace component or a simple automotive part, {Company Name} has the expertise and capability to deliver the perfect solution. This versatility allows manufacturers to streamline their production processes and reduce the need for multiple suppliers, ultimately saving time and money.Furthermore, {Company Name} takes pride in its commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly seeking new ways to enhance its CNC milling parts and stay ahead of the competition. This focus on innovation ensures that customers always have access to the latest advancements in milling technology, keeping their operations at the forefront of the industry.The launch of {Company Name}'s CNC milling parts represents a significant milestone for the company and its customers. By combining precision, durability, versatility, and innovation, {Company Name} has set a new standard for milling parts that will shape the future of manufacturing. With these cutting-edge products, manufacturers can expect improved efficiency, reduced downtime, and ultimately, a competitive edge in their respective industries.As {Company Name} continues to expand its product offerings and capabilities, it remains committed to providing superior solutions for the manufacturing industry. With a strong emphasis on quality, reliability, and customer satisfaction, the company is well-positioned to meet the evolving needs of modern manufacturing and drive the industry forward.For manufacturers looking to elevate their production capabilities, {Company Name}'s CNC milling parts offer a compelling solution. With a focus on precision, durability, versatility, and innovation, these parts are poised to make a lasting impact on the manufacturing industry and empower businesses to thrive in an increasingly competitive marketplace.

Discover the Latest Developments in CNC Machining Turning Parts

Title: Innovations in CNC Machining Turning Parts Drive Efficiency and Precision in ManufacturingIntroduction:In the fast-paced world of manufacturing, CNC machining turning parts play a crucial role in creating high-quality products with optimal precision and efficiency. These parts are at the forefront of numerous industries, including aerospace, automotive, electronics, and more. One prominent company leading the charge in this field is {}, which has continuously pushed the boundaries of innovation in CNC machining turning parts to meet the ever-evolving needs of the industry.Body:I. Overview of CNC Machining Turning PartsCNC machining turning parts, also known as lathe parts, are essential components in modern manufacturing processes. These parts are created through computer numerical control (CNC) technology, ensuring precise and accurate shaping of various materials such as metals, plastics, and composites. They serve as the building blocks for intricate designs, enabling the creation of complex components with reduced lead time and improved efficiency.II. Advancements in CNC Machining Turning Parts by {}With a rich history and vast experience in the field, {} has emerged as a global leader in CNC machining turning parts. The company has consistently embraced cutting-edge technologies and innovative techniques to revolutionize the manufacturing landscape. Here are some key advancements pioneered by {}:a. High-speed machining: {} has developed high-speed CNC turning technology, significantly reducing production time without compromising quality. This innovation allows for faster material removal rates, higher spindle speeds, and enhanced surface finishes. By optimizing tool paths and utilizing advanced coolant systems, {} ensures that their CNC turning parts are manufactured with supreme precision.b. Multi-axis machining: To meet the demands of increasingly complex designs, {} has integrated multi-axis machining capabilities into their CNC turning processes. By utilizing advanced software and multi-axis turning centers, the company can produce intricate components with multiple geometries. This innovation eliminates the need for multiple setups, reducing production time and ensuring dimensional accuracy.c. Automation and robotics: Recognizing the importance of automation in modern manufacturing, {} has embraced robotics to enhance their CNC machining turning processes. The company has integrated robotic loading and unloading systems, reducing manual handling and increasing production efficiency. Automation also allows for continuous operation, reducing downtime and enhancing overall productivity.III. Industry Applications and BenefitsThe technological advancements achieved by {} in CNC machining turning parts have had a profound impact on various industry sectors. Some notable applications and associated benefits include:a. Aerospace: Precision and reliability are paramount in the aerospace industry. By using {}'s CNC turning parts, aerospace manufacturers can ensure the production of critical components with the highest degree of accuracy, contributing to enhanced safety and performance of aircraft.b. Automotive: In the automotive sector, where constant innovation and cost efficiency are key drivers, {}'s CNC turning parts enable the production of engine components, transmission parts, and precision gears. The high-speed machining capabilities provide unparalleled accuracy, allowing automakers to meet stringent performance standards.c. Electronics: With the growing demand for miniaturization and intricate designs in electronic devices, {}'s CNC turning parts cater to the production of connectors, contacts, and other sensitive components. Their multi-axis machining capabilities enable the fabrication of intricate structures, crucial for electronic devices' functionality.d. Medical: In the medical field, where precision and reliability are critical, {}'s CNC turning parts find extensive use in the manufacturing of surgical instruments, implants, and devices. The company's focus on high-speed machining ensures the quick production of high-quality medical components, contributing to improved patient outcomes.IV. Future Outlook and ConclusionAs technology continues to advance, the future of CNC machining turning parts looks promising. {} remains at the forefront of this industry, constantly pushing boundaries and exploring new horizons. The company's commitment to research and development, along with its dedication to delivering superior quality products, contributes to the thriving manufacturing sector. With {}'s innovative CNC machining turning parts, manufacturers across industries can unlock new levels of efficiency, precision, and competitiveness.In conclusion, CNC machining turning parts are the driving force behind the modern manufacturing industry's evolution. The advancements pioneered by {} have revolutionized the field, enabling the production of high-quality components with unmatched precision. By continuously exploring new frontiers in technology and embracing innovation, {}, devoid of brand name, continues to set new standards in CNC machining turning parts, proving itself as an industry leader in providing cutting-edge solutions to meet the evolving needs of manufacturing.