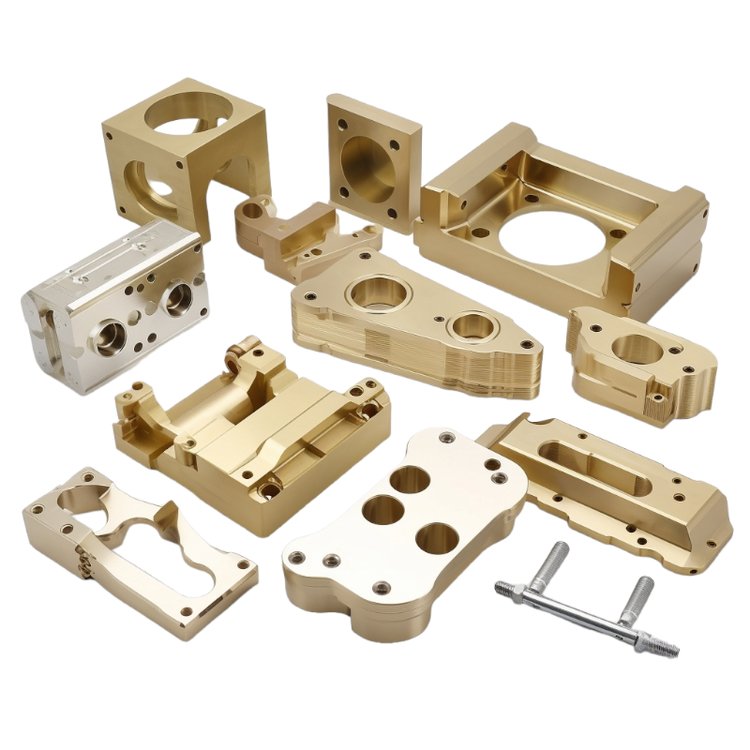

High-quality Anodized Aluminum Parts for Various Applications

By:Admin

The global Anodized Aluminum Parts market size was XX million US$ and is expected to reach XX million US$ by the end of 2026, with a CAGR of XX% during 2021-2026.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

The global Anodized Aluminum Parts market is expecting significant growth driven by factors such as increasing demand from end-use industries like automotive, aerospace, and construction, which require anodized aluminum parts for various manufacturing and assembly processes.

In the automotive industry, anodized aluminum parts are used in components like body panels, trim, wheels, and other critical parts, due to their lightweight and corrosion-resistant properties. This market is further driven by the increasing production and sales of automobiles worldwide.

In the aerospace industry, anodized aluminum parts are used in aircraft construction and components because of their high strength-to-weight ratio, corrosion resistance, and the ability to withstand harsh environmental conditions.

In the construction industry, anodized aluminum parts are used in architectural applications such as window frames, roofing, cladding, and curtain walls due to their aesthetic appeal, durability, and low maintenance requirements.

The Asia-Pacific region is expected to witness significant growth in the anodized aluminum parts market, driven by the rapid industrialization and urbanization in countries such as China, India, and Japan. The increasing construction and automotive sectors in the region are contributing to the demand for anodized aluminum parts.

North America and Europe are also prominent regions in the anodized aluminum parts market due to the presence of major automotive and aerospace manufacturers and the increasing demand for lightweight and durable materials in these industries.

[Company Name] is a leading manufacturer and supplier of anodized aluminum parts, offering a wide range of products to cater to the specific needs of various industries. With state-of-the-art facilities and a team of experienced professionals, [Company Name] is committed to delivering high-quality anodized aluminum parts that meet industry standards and customer specifications.

The company's anodized aluminum parts are known for their excellent corrosion resistance, enhanced durability, and aesthetically appealing finishes, making them suitable for diverse applications in automotive, aerospace, construction, and other industries. Utilizing advanced anodizing techniques, [Company Name] ensures that its products meet the highest quality standards and exceed customer expectations.

In addition to its extensive product range, [Company Name] also offers custom solutions and value-added services to meet specific customer requirements. With a focus on innovation and continuous improvement, the company remains at the forefront of the anodized aluminum parts market, providing reliable and efficient solutions to its global clientele.

As the demand for anodized aluminum parts continues to grow across various industries, [Company Name] is poised to capitalize on the opportunities and further strengthen its position as a leading player in the global market. With a strong commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of its customers and contribute to the growth of the anodized aluminum parts market.

Company News & Blog

High-quality CNC machining service in China

China CNC Machining Service Provider Exceeds Customer ExpectationsWith a commitment to precision, excellence, and customer satisfaction, China CNC Machining Service has established itself as a leading provider of high-quality machining services. The company, based in China, has built a reputation for delivering exceptional products to a wide range of industries, including aerospace, automotive, electronics, and medical devices.China CNC Machining Service takes pride in its state-of-the-art facility, which is equipped with advanced CNC machines and a team of highly skilled engineers and technicians. This combination of leading-edge technology and expertise allows the company to produce intricate parts and components with the highest level of accuracy and efficiency.One of the key factors that set China CNC Machining Service apart from its competitors is its ability to offer a comprehensive range of machining services. From milling and turning to grinding and prototyping, the company has the capabilities to meet the diverse needs of its clients. Whether it's a small batch of custom-made components or a large-scale production run, China CNC Machining Service can handle projects of any size and complexity.In addition to its cutting-edge machinery and technical proficiency, China CNC Machining Service is dedicated to providing excellent customer service. The company works closely with its clients to understand their unique requirements and specifications, ensuring that every project is completed to their exact satisfaction. From the initial consultation to the final delivery, the team at China CNC Machining Service is committed to exceeding customer expectations at every step of the process.With a focus on quality and precision, China CNC Machining Service has earned the trust and loyalty of a growing number of clients both domestically and internationally. Its reputation for delivering superior products on time and within budget has led to numerous long-term partnerships with some of the most prominent companies in the industry."We are proud to be recognized as a trusted provider of CNC machining services," said the spokesperson for China CNC Machining Service. "Our team's dedication to excellence and our relentless pursuit of customer satisfaction are the driving forces behind our success. We are constantly striving to innovate and improve our processes to continue meeting and exceeding the demands of our clients."As part of its commitment to continuous improvement, China CNC Machining Service invests in ongoing research and development to stay ahead of the curve in the ever-evolving field of machining technology. The company regularly upgrades its equipment and adopts the latest techniques and methodologies to ensure that it remains at the forefront of innovation.Furthermore, China CNC Machining Service places a strong emphasis on sustainability and environmental responsibility. The company adheres to strict environmental regulations and implements eco-friendly practices in its operations to minimize its carbon footprint and reduce waste. By embracing sustainable manufacturing principles, China CNC Machining Service aims to contribute to a healthier, more environmentally conscious future.In conclusion, China CNC Machining Service stands out as a premier provider of CNC machining solutions, catering to a diverse clientele across various industries. With its cutting-edge technology, skilled workforce, unwavering commitment to customer satisfaction, and dedication to sustainable manufacturing practices, the company continues to set the bar for excellence in the machining industry. As it moves forward, China CNC Machining Service remains committed to exceeding customer expectations and delivering precision-engineered products that meet the highest standards of quality and reliability.

Discover the Benefits of CNC Machined Prototypes for Your Business

CNC Machined Prototypes: Revolutionizing Product DevelopmentIn the fast-paced world of product development, the ability to quickly and accurately create prototypes is crucial. It allows companies to test their designs, refine their products, and ultimately bring them to market faster. This is where CNC machined prototypes come into play, offering a precise and efficient way to produce high-quality models for testing and evaluation.One company that has been making waves in the world of CNC machined prototypes is [Company Name Removed]. Founded in [Year Removed], the company has quickly established itself as a leader in the industry, offering a wide range of prototyping and manufacturing services to clients across various sectors, including aerospace, automotive, electronics, and medical devices.[Company Name Removed] prides itself on its state-of-the-art facilities and cutting-edge technology, which enable it to produce prototypes with an unparalleled level of precision and quality. The company's team of expert engineers and technicians work closely with clients to understand their specific requirements and design prototypes that meet their exact specifications.With a focus on innovation and continuous improvement, [Company Name Removed] is constantly investing in the latest CNC machining equipment and software to ensure that it stays ahead of the curve in terms of technology and capability. This commitment to staying at the forefront of the industry has allowed the company to take on complex and challenging projects, delivering prototypes that exceed client expectations time and time again.One of the key advantages of CNC machined prototypes is the speed at which they can be produced. Using computer-aided design (CAD) software, the company can quickly generate toolpaths and machine complex geometries with a high degree of accuracy. This means that clients can receive their prototypes in a fraction of the time it would take using traditional manufacturing methods, allowing them to accelerate their product development cycle and get their innovations to market faster.Additionally, CNC machined prototypes offer a level of accuracy and consistency that is difficult to achieve with other manufacturing techniques. This is particularly important for industries with stringent quality and performance requirements, such as aerospace and medical devices. By leveraging the precision of CNC machining, [Company Name Removed] is able to produce prototypes that closely resemble the final product, allowing clients to conduct rigorous testing and validation before moving into full-scale production.Moreover, CNC machined prototypes are versatile and can be produced from a wide range of materials, including metals, plastics, and composites. This means that [Company Name Removed] can cater to the diverse needs of its client base, whether they require prototypes for structural components, functional parts, or aesthetic models.In addition to its prototyping services, [Company Name Removed] also offers a range of other manufacturing capabilities, including CNC milling, turning, and grinding, as well as additive manufacturing processes like 3D printing. This comprehensive suite of services enables the company to support clients at every stage of their product development journey, from concept to production.As the demand for high-quality prototypes continues to grow, [Company Name Removed] is well-positioned to meet the needs of its clients and drive innovation across a variety of industries. With its unwavering commitment to excellence and its dedication to staying at the forefront of technology, the company is poised to remain a leader in the world of CNC machined prototypes for years to come.

Top High Precision CNC Machines: Latest Technology and Benefits

High Precision CNC Machine Empowers Company to Achieve Unprecedented Manufacturing ExcellenceIn today's increasingly competitive manufacturing landscape, companies are continuously seeking ways to improve precision, efficiency, and overall quality to stay ahead of the competition. For {company name}, the answer came in the form of a high precision CNC machine. By leveraging this cutting-edge technology, the company has been able to achieve unprecedented manufacturing excellence, solidifying its position as a leader in the industry.{Company name} is a renowned manufacturing company that specializes in the production of complex components for a wide range of industries, including aerospace, automotive, and medical. With a strong commitment to innovation and continuous improvement, the company is always on the lookout for the latest advancements in manufacturing technology. This dedication to staying at the forefront of industry trends led {company name} to invest in a state-of-the-art high precision CNC machine, which has revolutionized its manufacturing processes.The high precision CNC machine in question is a game-changer for {company name}. Equipped with advanced automation and cutting-edge software, the machine offers unparalleled levels of precision and accuracy, allowing for the production of complex and intricate components with remarkable consistency. This high level of precision has enabled {company name} to meet the exacting standards of its clients, many of whom operate in highly demanding industries where quality and precision are non-negotiable.Moreover, the high precision CNC machine has significantly enhanced {company name}'s efficiency and productivity. With its advanced capabilities, the machine is able to produce parts at a much faster rate than traditional manufacturing methods, effectively reducing lead times and allowing the company to fulfill orders in a more timely manner. This increased efficiency has not only improved customer satisfaction but has also streamlined {company name}'s internal operations, leading to cost savings and overall improved profitability.The implementation of the high precision CNC machine has not only elevated the quality and efficiency of {company name}'s manufacturing processes but has also expanded the range of components it can produce. With its advanced multi-axis capabilities and the ability to work with a diverse range of materials, the CNC machine has enabled {company name} to take on more complex and diverse projects, further solidifying its reputation as a versatile and reliable manufacturing partner.In addition to the technological capabilities of the high precision CNC machine, {company name} has also invested in training its workforce to maximize the potential of this cutting-edge equipment. By providing comprehensive training and development programs, the company has ensured that its employees are well-versed in the operation of the CNC machine, allowing them to fully leverage its capabilities and contribute to the company's success.Looking ahead, {company name} is committed to harnessing the full potential of the high precision CNC machine to drive further innovation and growth. By continually exploring new applications and pushing the boundaries of what the machine can achieve, the company aims to further differentiate itself in the market and continue setting new standards for manufacturing excellence.In conclusion, the integration of a high precision CNC machine has proven to be a transformative investment for {company name}. With its ability to deliver unrivaled precision, efficiency, and versatility, the CNC machine has empowered the company to achieve new heights of manufacturing excellence, driving its success and cementing its position as a leader in the industry. With a firm focus on innovation and continuous improvement, {company name} is poised to leverage the full potential of this cutting-edge technology to drive future growth and solidify its reputation as a manufacturing powerhouse.

High-Quality 6061 Aluminum for CNC Machining - Everything You Need to Know

CNC 6061 Aluminum: The Perfect Material for Precision MachiningIn the world of manufacturing and precision machining, the choice of materials is crucial. The right material can make all the difference in the quality and precision of the finished product. This is why many industries rely on CNC 6061 Aluminum for their machining needs. With its excellent machinability, strength, and corrosion resistance, CNC 6061 Aluminum has become a popular choice for a wide range of applications.CNC 6061 Aluminum is a versatile and durable material that is widely used in the aerospace, automotive, and marine industries, among others. Its high strength-to-weight ratio makes it an ideal choice for applications that require both strength and lightweight properties. This makes it an excellent choice for aerospace components, automotive parts, and marine equipment.One of the key advantages of CNC 6061 Aluminum is its excellent machinability. This material is easily machinable and can be shaped and formed into intricate designs with ease. This makes it an ideal choice for precision machining, where complex and intricate parts need to be manufactured with high accuracy and precision.In addition to its machinability, CNC 6061 Aluminum also offers excellent corrosion resistance. This makes it an ideal choice for applications that require resistance to harsh environments, such as marine and aerospace applications. Its ability to withstand corrosion makes it a cost-effective and reliable choice for these industries.Furthermore, CNC 6061 Aluminum can be easily welded and fabricated, making it a versatile material for a wide range of applications. Its ability to be easily formed and welded allows for the creation of complex and intricate designs, making it an ideal choice for custom-made parts and components.In fact, many industries have come to rely on CNC 6061 Aluminum for their precision machining needs. This includes the automotive industry, where CNC 6061 Aluminum is used to manufacture a wide range of components, such as engine parts, chassis components, and suspension systems. Its high strength and excellent machinability make it an ideal choice for these applications.Additionally, the aerospace industry also heavily relies on CNC 6061 Aluminum for its precision machining needs. The material's lightweight properties and high strength-to-weight ratio make it an ideal choice for aerospace components, such as aircraft structures, landing gear, and engine components. Its ability to withstand harsh environments and corrosion resistance further makes it a reliable choice for aerospace applications.At {Company Name}, we specialize in precision machining and have extensive experience working with CNC 6061 Aluminum. Our state-of-the-art facilities and highly skilled machinists allow us to produce high-quality machined components with tight tolerances and complex designs. We understand the unique properties of CNC 6061 Aluminum and are capable of delivering parts that meet the exact specifications of our clients.In addition to our expertise in precision machining, we also offer a range of secondary processes, such as anodizing, plating, and finishing, to provide our clients with a complete solution for their machining needs. Our commitment to quality and customer satisfaction has earned us a reputation as a trusted partner for precision machining projects.Overall, CNC 6061 Aluminum is the perfect material for precision machining, offering excellent machinability, strength, and corrosion resistance. With its versatility and reliability, it has become a popular choice for a wide range of industries. At {Company Name}, we are proud to offer our expertise in working with CNC 6061 Aluminum, delivering high-quality machined components that meet the exact specifications of our clients.

High Quality Cnc Machine: A complete guide

The manufacturing industry is in for a major revolution with the introduction of the latest high-quality CNC machine by leading company. This groundbreaking development is set to redefine precision engineering and machining capabilities, ushering in a new era of innovation and efficiency in the manufacturing sector.Company has been at the forefront of technological advancements in the manufacturing industry for over a decade. With a strong commitment to quality, reliability, and excellence, the company has established itself as a market leader in providing advanced solutions for precision engineering and machining. The introduction of the new high-quality CNC machine is a testament to their ongoing dedication to pushing the boundaries of what is possible in the manufacturing realm.This state-of-the-art CNC machine is equipped with the latest cutting-edge technology, setting new standards for precision, speed, and versatility. Its advanced features and capabilities make it the ideal choice for a wide range of machining applications, from simple parts production to complex, intricate designs. With its high-speed spindle and advanced control system, this CNC machine offers unparalleled precision and accuracy, ensuring that every workpiece is machined with uncompromising perfection.The superior performance of this CNC machine is further enhanced by its robust build quality and advanced engineering. With a solid, durable construction, it is built to withstand the rigors of high-speed machining, delivering consistent, reliable results with every operation. Furthermore, its user-friendly interface and intuitive controls make it easy to operate, allowing operators to maximize productivity and efficiency without compromising on quality.The introduction of this high-quality CNC machine is set to have a transformative impact on the manufacturing industry. Its advanced capabilities will enable manufacturers to produce parts and components with unparalleled precision and efficiency, leading to significant improvements in productivity and cost-effectiveness. Moreover, its versatility and adaptability make it an invaluable asset for a wide range of industries, from aerospace and automotive to medical and electronics.In addition to its impressive technical specifications, this CNC machine is also designed with sustainability and environmental responsibility in mind. It incorporates energy-efficient technologies and eco-friendly materials, minimizing its carbon footprint and contributing to a more sustainable manufacturing process. This aligns with the company's commitment to environmental stewardship and corporate social responsibility, ensuring that their products are not only cutting-edge but also environmentally conscious.Furthermore, the company is dedicated to providing comprehensive support and service for their high-quality CNC machine, ensuring that their customers have access to expert guidance and assistance when needed. With a team of highly skilled technicians and engineers, they offer prompt technical support, maintenance services, and training programs to ensure that their customers can maximize the potential of their CNC machine.Overall, the introduction of this high-quality CNC machine represents a significant milestone in the evolution of precision engineering and machining. Its advanced features, exceptional performance, and environmental consciousness make it a game-changer in the manufacturing industry, offering unparalleled capabilities for manufacturers to elevate their production processes and achieve new heights of excellence. With the backing of a reputable industry leader, this CNC machine is set to revolutionize the way manufacturers approach precision engineering and machining, setting new standards for quality, innovation, and sustainability.

Top Ways Custom CNC Steel Fabrication Can Benefit Your Business

Custom CNC Steel celebrates 20 years of precision engineering excellenceCustom CNC Steel is marking two decades of success in the precision engineering industry, demonstrating its commitment to quality and innovation. Since its inception in 2001, the company has built a reputation for producing high-quality components and parts for a wide range of industries.Based in (location), Custom CNC Steel offers custom machining solutions to meet the unique requirements of its diverse customer base. With a focus on precision and efficiency, the company has become a trusted partner for clients in aerospace, automotive, medical, and other industries requiring high-quality precision parts.The company's success can be attributed to its state-of-the-art facilities and advanced CNC machining capabilities. With a team of experienced engineers and technicians, Custom CNC Steel has the expertise and resources to deliver precise and complex components with tight tolerances.In addition to its advanced machining capabilities, Custom CNC Steel also prides itself on its commitment to customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, providing personalized solutions that meet and exceed expectations. This customer-centric approach has solidified Custom CNC Steel's reputation as a reliable and trusted partner in the precision engineering industry.To celebrate its 20th anniversary, Custom CNC Steel is planning a series of events and activities to commemorate this significant milestone. The company will be hosting an open house event at its facility, allowing customers, suppliers, and partners to tour the state-of-the-art manufacturing facility and learn more about the company's capabilities and achievements.In addition to the open house event, Custom CNC Steel will also be launching a new website to showcase its portfolio of products and services. The website will highlight the company's expertise in CNC machining, as well as its commitment to quality, innovation, and customer satisfaction.Reflecting on the company's 20-year journey, (CEO or company spokesperson) expressed gratitude to the employees, customers, and partners who have contributed to Custom CNC Steel's success. "We are incredibly proud of what we have accomplished over the past two decades," said (CEO or company spokesperson). "Our commitment to quality, precision, and customer satisfaction has been the foundation of our success, and we are excited to continue serving our customers with excellence in the years to come."Looking ahead, Custom CNC Steel is focused on expanding its capabilities and exploring new opportunities for growth and innovation. With a strong track record of delivering high-quality precision components, the company is well-positioned to take on new challenges and further solidify its reputation as a leader in the precision engineering industry.As Custom CNC Steel celebrates its 20th anniversary, the company remains dedicated to its core values of quality, innovation, and customer satisfaction. With a focus on precision engineering and personalized solutions, Custom CNC Steel is poised to continue its success and make a lasting impact in the industry for years to come.

Quality High Precision Machining Components for Various Industries

High Precision Machining Components, a leading manufacturer of high quality precision components, continues to deliver exceptional products and services to its customers. With a commitment to innovation and excellence, the company has established itself as a trusted partner for industries in need of precision machined parts.Since its establishment, High Precision Machining Components has garnered a reputation for producing top-notch products, thanks to its advanced manufacturing capabilities and stringent quality control processes. The company's state-of-the-art facility is equipped with the latest CNC machining technology, allowing for the production of complex and intricate components with tight tolerances.One of the key strengths of High Precision Machining Components is its team of highly skilled engineers and machinists, who possess a wealth of knowledge and experience in the field of precision machining. Their expertise and attention to detail ensure that each component meets the exact specifications and requirements of the customer.In addition to its cutting-edge technology and talented workforce, High Precision Machining Components places a strong emphasis on customer satisfaction. The company works closely with each client to understand their specific needs and provide tailored solutions that meet or exceed expectations. This customer-centric approach has earned High Precision Machining Components a loyal and satisfied customer base.Furthermore, High Precision Machining Components is committed to continuous improvement and investing in research and development to stay ahead of industry trends. By staying at the forefront of technological advancements, the company is able to offer innovative solutions that drive efficiency and performance for its customers.As a testament to its commitment to quality and excellence, High Precision Machining Components holds various industry certifications and adheres to strict quality standards. The company is dedicated to delivering products that not only meet industry requirements but also exceed them, ensuring the highest level of performance and reliability.In line with its dedication to excellence, High Precision Machining Components is constantly seeking new opportunities to expand its capabilities and reach new markets. The company's strong track record and reputation for delivering superior products make it a preferred choice for industries such as aerospace, automotive, medical, and more.High Precision Machining Components understands the importance of staying ahead of the curve in a rapidly evolving industry, and as such, it continues to invest in advanced technology and training for its employees. By doing so, the company remains well-positioned to tackle the challenges of tomorrow and continue providing high-quality precision components to its customers.In conclusion, High Precision Machining Components stands as a shining example of an industry leader that is committed to excellence, innovation, and customer satisfaction. With its cutting-edge technology, skilled workforce, and unwavering dedication to quality, the company is poised for continued success and growth in the field of precision machining.

High-Quality Aluminium CNC Service for Your Precision Machining Needs

Aluminium Cnc Service, a leading provider of precision CNC machining and fabrication services, continues to expand its capabilities and expertise in the industry. The company, which has been in operation for over [X] years, has built a strong reputation for its dedication to quality, efficiency, and customer satisfaction.Specializing in the production of high-precision components and parts made from aluminum, Aluminium Cnc Service has a state-of-the-art facility equipped with the latest CNC machines and technology. This allows the company to offer a wide range of services, including milling, turning, drilling, and tapping, as well as 3D machining and rapid prototyping. With a team of experienced engineers and machinists, Aluminium Cnc Service is able to meet the diverse needs of its customers, from small-scale projects to large-volume production runs.In addition to its advanced machining capabilities, Aluminium Cnc Service also provides a range of value-added services, such as finishing, assembly, and packaging. This enables the company to offer comprehensive solutions to its customers, ensuring that their projects are completed to the highest standards and delivered on time.Moreover, the company takes pride in its commitment to quality and precision. It operates under strict quality control measures, ensuring that every component produced meets the exact specifications and requirements of the customer. Aluminium Cnc Service is also dedicated to continuous improvement, regularly investing in new technology and training to stay ahead of industry trends and deliver the best possible results to its customers.Recently, Aluminium Cnc Service announced the acquisition of a new state-of-the-art CNC machine, further enhancing its capabilities and capacity. The new machine, equipped with advanced features and capabilities, will allow the company to take on even more complex and challenging projects. This investment reflects Aluminium Cnc Service's ongoing commitment to staying at the forefront of the industry and providing its customers with the highest quality products and services."We are excited to add this new CNC machine to our facility," said [X], the CEO of Aluminium Cnc Service. "It represents our dedication to meeting the evolving needs of our customers and maintaining our position as a leader in precision machining and fabrication. With this new machine, we will be able to offer even more comprehensive solutions and take on a wider range of projects, further solidifying our reputation as a reliable and innovative partner."The acquisition of the new CNC machine comes at a time of significant growth for Aluminium Cnc Service. The company has seen an increase in demand for its services across various industries, including aerospace, automotive, electronics, and industrial manufacturing. This growth is a testament to the company's strong track record of delivering high-quality products, as well as its ability to adapt to the changing needs of its customers.Looking ahead, Aluminium Cnc Service is committed to continuing its growth and expansion, with plans to invest in additional equipment and technology to further enhance its capabilities. The company also aims to continue building strong relationships with its customers, providing them with the best possible solutions and support for their projects.In conclusion, Aluminium Cnc Service is a leading provider of precision CNC machining and fabrication services, with a strong focus on quality, efficiency, and customer satisfaction. The company's investment in new technology and its commitment to continuous improvement make it a reliable and innovative partner for customers across various industries. As Aluminium Cnc Service continues to expand its capabilities and expertise, it is well-positioned to meet the evolving needs of its customers and maintain its position as a leader in the industry.

Experienced CNC Mechanic: Essential Skills and Qualities for the Job

We are pleased to announce that the highly reputable company {} is now offering a new and exciting service - CNC Mechanic. This new addition to their already impressive array of services solidifies their position as a leader in the industry.CNC Mechanic is a crucial service in today's manufacturing industry, and {} has recognized the growing demand for skilled professionals in this field. With the expansion of their services to include CNC Mechanic, {} is now able to provide comprehensive solutions to their clients' manufacturing needs.The term "CNC" stands for Computer Numerical Control, which involves the use of computers to control machine tools and 3D printers in order to produce highly precise and complex parts. CNC Mechanic is a specialized field that requires a high level of skill and expertise, and {} has made sure to handpick a team of highly trained professionals to offer this service.With the introduction of CNC Mechanic, {} is now able to cater to a wider range of industries, including automotive, aerospace, medical, and many others. Their team of experts is capable of handling a variety of tasks, including programming, setup, and maintenance of CNC machines, as well as troubleshooting and diagnosing issues that may arise during the manufacturing process.{} has always prided itself on providing top-notch services to its clients, and the addition of CNC Mechanic is a testament to their commitment to staying ahead of the curve. With this new service, they are able to offer a more complete and integrated solution to their clients, allowing them to streamline their manufacturing processes and produce high-quality parts with utmost precision.The team at {} is well-equipped with state-of-the-art tools and equipment to ensure that they are able to deliver top-quality results for their clients. Their dedication to staying at the forefront of technological advancements in the industry has made them a go-to partner for businesses looking to take their manufacturing processes to the next level.Furthermore, {} understands that each client may have unique needs and requirements, and they are dedicated to providing customized solutions that are tailored to meet those specific needs. Whether it's a small-scale production or a large-scale manufacturing project, {} is able to handle it all with the utmost professionalism and dedication.As a company, {} has always been driven by a desire to exceed their clients' expectations, and the addition of CNC Mechanic is just one more step in that direction. With this new service, they are able to offer an even more comprehensive and holistic approach to manufacturing, providing their clients with the peace of mind that comes with knowing that their projects are in the hands of true professionals.In conclusion, the introduction of CNC Mechanic by {} is a clear indication of their commitment to staying at the forefront of the industry. With this new service, they are able to offer an even more complete and integrated solution to their clients, solidifying their position as a leader in the manufacturing industry. Businesses looking to elevate their manufacturing processes should look no further than {} for top-quality CNC Mechanic services.

High-Quality Metal Part and CNC Machining Services in China

China Metal Part and CNC Machining, a leading provider of precision metal parts and machining services, has been making waves in the industry with its dedication to quality, efficiency, and innovation.With a state-of-the-art facility and a team of highly skilled engineers and machinists, China Metal Part and CNC Machining offers a wide range of metal parts and machining services to meet the diverse needs of its clients. The company specializes in CNC milling, turning, grinding, EDM, and precision engineering. Its capabilities allow for the production of complex and intricate parts with tight tolerances and high precision.China Metal Part and CNC Machining serves various industries, including automotive, aerospace, medical, and electronics. The company's commitment to excellence has earned it a reputation for delivering top-notch products that meet the highest standards of quality and performance.One of the key factors that sets China Metal Part and CNC Machining apart from its competitors is its ability to provide custom solutions to its clients. The company works closely with its customers to understand their specific requirements and then leverages its expertise and cutting-edge technology to deliver tailor-made solutions that meet and exceed expectations.In addition to its strong focus on quality and customization, China Metal Part and CNC Machining also places a high emphasis on efficiency and cost-effectiveness. The company is continuously investing in the latest machinery and technology to streamline its production processes and reduce lead times, ultimately benefiting its clients by delivering high-quality products in a timely manner.Furthermore, China Metal Part and CNC Machining is dedicated to staying ahead of the curve when it comes to innovation. The company keeps a close eye on industry trends and technological advancements, allowing it to constantly improve its capabilities and offer cutting-edge solutions to its clients.The success of China Metal Part and CNC Machining can be attributed to its unwavering commitment to customer satisfaction. The company places a strong emphasis on building and maintaining strong relationships with its clients, working collaboratively with them to meet their needs and exceed their expectations.As China Metal Part and CNC Machining continues to grow and expand, it remains focused on upholding its core values of quality, efficiency, innovation, and customer satisfaction. With a strong track record of success and a dedication to excellence, the company is poised to remain a leader in the industry for years to come.In conclusion, China Metal Part and CNC Machining has established itself as a trusted and reliable partner for companies seeking precision metal parts and machining services. With its focus on quality, efficiency, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of its clients and maintain its status as a leader in the industry.