Advanced CNC Machining of Metal: The Future of Manufacturing

By:Admin

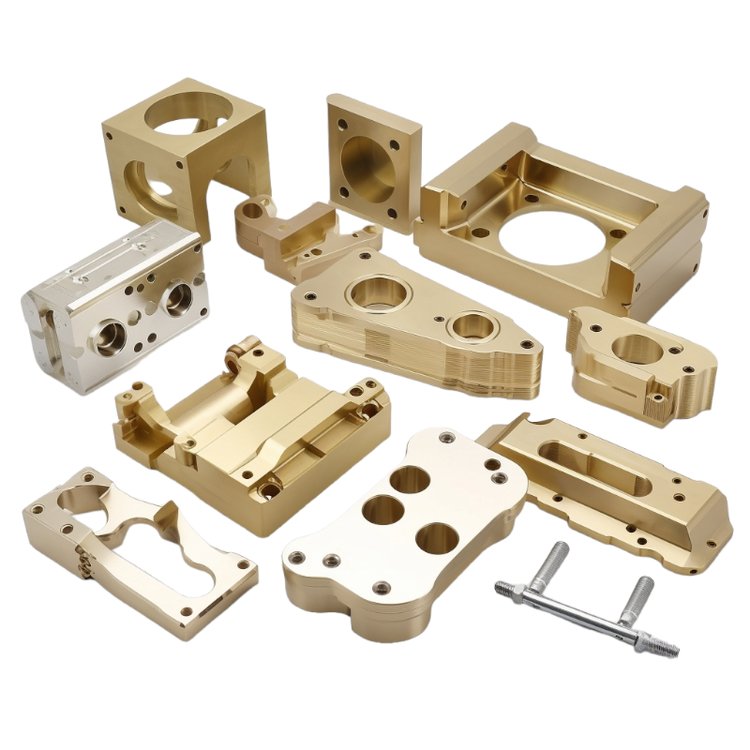

In the world of manufacturing, precision and efficiency are key factors in determining the success of a company. With the advancements in technology, CNC machining has become the go-to process for creating high-quality, complex metal parts. The use of computer numerical control (CNC) machines has revolutionized the manufacturing industry, allowing for faster production, higher precision, and increased flexibility in design. With the integration of innovative technologies, the future of CNC machining metal has never seemed brighter.

One company that is at the forefront of this technological revolution is {}. With a strong dedication to quality and customer satisfaction, {} has established itself as a leader in the CNC machining industry. Specializing in the production of precision metal components, {} has built a reputation for delivering superior products and exceptional service to its clients.

The key to {}'s success lies in its state-of-the-art equipment and the expertise of its skilled machinists. Utilizing the latest CNC machines, {} is able to produce parts with incredibly tight tolerances and intricate designs. This level of precision is essential in industries such as aerospace, automotive, and medical, where the demand for high-quality components is paramount.

In addition to its cutting-edge machinery, {} is continuously investing in new technologies to enhance its manufacturing capabilities. One such technology is the use of advanced software for CAD/CAM programming. This software allows {} to create complex 3D models of parts and simulate the machining process, ensuring that every component is manufactured with the utmost accuracy.

Furthermore, {} is committed to sustainability and environmental responsibility. By implementing efficient manufacturing processes and optimizing material usage, the company aims to minimize waste and reduce its carbon footprint. This commitment to sustainability not only benefits the environment but also allows {} to offer cost-effective solutions to its clients.

The future of CNC machining metal is not only about the technology itself, but also about how it is applied to meet the evolving needs of the industry. {} understands the importance of staying ahead of the curve and is constantly exploring new methods to enhance its manufacturing capabilities. Whether it's through the adoption of additive manufacturing techniques or the integration of robotics in the production process, {} is dedicated to pushing the boundaries of what is possible in CNC machining.

Moreover, {} places a strong emphasis on collaboration and communication with its clients. The company works closely with its customers to understand their specific requirements and provide tailored solutions to meet their needs. By fostering strong partnerships, {} is able to deliver not just parts, but complete manufacturing solutions that add value to its clients' businesses.

As the demand for precision metal components continues to grow, {} is poised to play a pivotal role in shaping the future of CNC machining. With its unwavering commitment to quality, innovation, and customer satisfaction, {} is well-positioned to lead the way in this rapidly evolving industry.

In conclusion, the future of CNC machining metal is full of promise, and {}. The company's dedication to excellence, investment in cutting-edge technologies, and focus on sustainability make it a key player in the industry. As technology continues to advance, {} will undoubtedly be at the forefront, driving innovation and delivering superior manufacturing solutions to its clients. With {} leading the way, the future of CNC machining metal looks brighter than ever.

Company News & Blog

Expert Guide to Gear Cutting: Everything You Need to Know

Custom Gear Cutting, a leading manufacturing company in the mechanical engineering industry, is proud to announce the expansion of its services to meet the increasing demand for precision gear cutting solutions. With over {number of years} years of experience in the industry, Custom Gear Cutting has established a strong reputation for delivering high-quality, reliable, and cost-effective gear cutting services to a wide range of clients.Custom Gear Cutting specializes in the design and production of custom gears, splines, and sprockets for various applications including automotive, aerospace, industrial machinery, and more. The company's state-of-the-art manufacturing facility is equipped with the latest gear cutting technology and machinery, allowing them to produce precision-engineered gears that meet the highest industry standards.The company's team of highly skilled engineers and technicians are dedicated to providing innovative and tailored solutions to meet their clients' specific gear cutting needs. Whether it's a complex gear geometry, tight tolerances, or unique material requirements, Custom Gear Cutting has the expertise and capabilities to deliver customized gear cutting solutions that exceed expectations.In addition to their custom gear cutting services, Custom Gear Cutting also offers a range of value-added services including gear hobbing, gear shaping, gear grinding, and gear inspection. This comprehensive approach allows the company to provide end-to-end gear manufacturing solutions, from design and prototyping to production and quality control.With a commitment to customer satisfaction and continuous improvement, Custom Gear Cutting is constantly investing in new technologies and process enhancements to ensure that they remain at the forefront of the industry. This dedication to innovation and excellence has enabled the company to build long-standing relationships with a diverse portfolio of clients, from small businesses to multinational corporations."We are excited to expand our gear cutting capabilities to better serve the evolving needs of our customers," said [spokesperson name], [job title] at Custom Gear Cutting. "As a customer-focused company, we are dedicated to providing tailored solutions that address the unique challenges of our clients. Our team is passionate about delivering top-quality products and services that drive success and innovation in the industry."Custom Gear Cutting's commitment to quality and customer satisfaction is evident in their ISO [insert ISO certification number] certification, which demonstrates their adherence to rigorous quality management standards. This certification is a testament to the company's dedication to excellence and their ability to consistently deliver superior products and services.As Custom Gear Cutting continues to expand its capabilities and offerings, the company remains committed to upholding its core values of integrity, innovation, and reliability. With a focus on delivering exceptional gear cutting solutions and building lasting partnerships with their clients, Custom Gear Cutting is poised to remain a trusted leader in the industry for years to come.For more information about Custom Gear Cutting and their comprehensive gear cutting services, visit their website at www.customgearcutting.com.

Ultimate Guide to Ordering Custom CNC Parts Online Revealed in Recent News

Custom CNC Parts Online: Revolutionizing Manufacturing IndustriesIn today's fast-paced and ever-changing world, technology continues to transform various industries, and manufacturing is no exception. One such company making waves in the manufacturing world is Custom CNC Parts Online. With its innovative approach to fabrication and production, this company is reshaping the way products are made.Founded in (year),Custom CNC Parts Online has quickly gained recognition as a leader in the CNC (Computer Numerical Control) machining industry. Their online platform allows customers to design and order custom-made parts with ease and efficiency. By capitalizing on advancements in technology and automation, the company is able to offer high-quality parts at competitive prices, revolutionizing the manufacturing process for businesses of all sizes.The backbone of Custom CNC Parts Online is its state-of-the-art manufacturing facility, which houses a wide range of advanced machinery. These include CNC milling machines, lathes, and routers, capable of handling various materials like metals, plastics, and composites with precision and accuracy. With a team of experienced engineers and technicians, the company ensures that each part is manufactured to meet the exact specifications of its customers.The user-friendly online platform enables customers to upload their design files, select the desired material, and specify any additional requirements or finishes. Once the order is received, Custom CNC Parts Online's intelligent system processes the design and allocates the most suitable machine to complete the job. This streamlines the production process, reducing the time required to manufacture the parts without compromising on quality.In addition to offering a user-friendly interface, Custom CNC Parts Online also maintains a high level of communication with its customers. The company provides real-time updates on the progress of the manufacturing process, ensuring transparency and allowing customers to track the status of their orders. This commitment to customer service has helped build trust and loyalty among their growing customer base.Another noteworthy advantage offered by Custom CNC Parts Online is its ability to cater to both large-scale industrial projects and small-scale custom orders. With their advanced manufacturing capabilities, the company is well-equipped to handle high-volume production runs, delivering large quantities of parts in a timely manner. Simultaneously, they also excel at catering to the unique requirements of small businesses or individuals seeking specialized components.Custom CNC Parts Online's commitment to quality is evident in their production process. Every part undergoes rigorous testing and inspection before it is deemed ready to be shipped to the customer. By maintaining strict quality control protocols, the company ensures that each fabricated part meets or exceeds industry standards.Furthermore, the company's dedication to sustainability sets them apart from their competitors. Custom CNC Parts Online utilizes eco-friendly practices throughout their manufacturing process, including the recycling of waste materials and the use of energy-efficient machinery. This commitment to environmental responsibility aligns with the increasing global emphasis on sustainable manufacturing practices.Custom CNC Parts Online is not only transforming the manufacturing industry but also democratizing access to CNC machining services. In the past, CNC machining was often associated with high costs and long lead times. However, with their efficient production process and competitive prices, Custom CNC Parts Online has made CNC machining accessible to a broader range of businesses and individuals.Looking towards the future, Custom CNC Parts Online plans to expand its product offerings and continue investing in research and development. The company recognizes the importance of staying at the forefront of technological advancements to meet the evolving needs of the manufacturing industry. Through ongoing innovation and a commitment to customer satisfaction, Custom CNC Parts Online aims to solidify its position as a leader in the CNC machining sector.In conclusion, Custom CNC Parts Online has revolutionized the manufacturing industry by providing a convenient online platform for businesses and individuals to design and order custom-made parts. Through their advanced manufacturing capabilities, commitment to quality, and environmental sustainability, the company has gained recognition as a leader in the CNC machining sector. With their sights set on the future, Custom CNC Parts Online is poised to further transform and shape the manufacturing industry for years to come.

High-quality CNC machining service in China

China CNC Machining Service Provider Exceeds Customer ExpectationsWith a commitment to precision, excellence, and customer satisfaction, China CNC Machining Service has established itself as a leading provider of high-quality machining services. The company, based in China, has built a reputation for delivering exceptional products to a wide range of industries, including aerospace, automotive, electronics, and medical devices.China CNC Machining Service takes pride in its state-of-the-art facility, which is equipped with advanced CNC machines and a team of highly skilled engineers and technicians. This combination of leading-edge technology and expertise allows the company to produce intricate parts and components with the highest level of accuracy and efficiency.One of the key factors that set China CNC Machining Service apart from its competitors is its ability to offer a comprehensive range of machining services. From milling and turning to grinding and prototyping, the company has the capabilities to meet the diverse needs of its clients. Whether it's a small batch of custom-made components or a large-scale production run, China CNC Machining Service can handle projects of any size and complexity.In addition to its cutting-edge machinery and technical proficiency, China CNC Machining Service is dedicated to providing excellent customer service. The company works closely with its clients to understand their unique requirements and specifications, ensuring that every project is completed to their exact satisfaction. From the initial consultation to the final delivery, the team at China CNC Machining Service is committed to exceeding customer expectations at every step of the process.With a focus on quality and precision, China CNC Machining Service has earned the trust and loyalty of a growing number of clients both domestically and internationally. Its reputation for delivering superior products on time and within budget has led to numerous long-term partnerships with some of the most prominent companies in the industry."We are proud to be recognized as a trusted provider of CNC machining services," said the spokesperson for China CNC Machining Service. "Our team's dedication to excellence and our relentless pursuit of customer satisfaction are the driving forces behind our success. We are constantly striving to innovate and improve our processes to continue meeting and exceeding the demands of our clients."As part of its commitment to continuous improvement, China CNC Machining Service invests in ongoing research and development to stay ahead of the curve in the ever-evolving field of machining technology. The company regularly upgrades its equipment and adopts the latest techniques and methodologies to ensure that it remains at the forefront of innovation.Furthermore, China CNC Machining Service places a strong emphasis on sustainability and environmental responsibility. The company adheres to strict environmental regulations and implements eco-friendly practices in its operations to minimize its carbon footprint and reduce waste. By embracing sustainable manufacturing principles, China CNC Machining Service aims to contribute to a healthier, more environmentally conscious future.In conclusion, China CNC Machining Service stands out as a premier provider of CNC machining solutions, catering to a diverse clientele across various industries. With its cutting-edge technology, skilled workforce, unwavering commitment to customer satisfaction, and dedication to sustainable manufacturing practices, the company continues to set the bar for excellence in the machining industry. As it moves forward, China CNC Machining Service remains committed to exceeding customer expectations and delivering precision-engineered products that meet the highest standards of quality and reliability.

5 Tips for Achieving Chiseled Abs Through Machined Workouts

Machined Abs is a cutting-edge fitness equipment company that has been in the industry for over a decade. The company specializes in producing high-quality abdominal exercise machines that are designed to help individuals achieve their fitness goals. With a focus on innovation and effectiveness, Machined Abs has established itself as a leading provider of top-notch fitness equipment.The company's dedication to producing the best abdominal exercise machines on the market has resulted in a range of products that are known for their outstanding performance and durability. Each machine is carefully crafted using the finest materials and cutting-edge technology to ensure that users get the most out of their workouts.One of the key features of Machined Abs' products is their ergonomic design, which is crucial for preventing injury and promoting proper form during workouts. The machines are also highly versatile, making them ideal for individuals of all fitness levels. Whether you are a beginner looking to tone and strengthen your abs or a seasoned fitness enthusiast aiming to take your workouts to the next level, Machined Abs has the perfect solution for you.In addition to their commitment to quality, Machined Abs also prioritizes customer satisfaction. The company strives to provide exceptional customer service and support, ensuring that each customer has a positive experience from the moment they make a purchase. This dedication to excellence has earned Machined Abs a loyal customer base and a stellar reputation in the fitness industry.Machined Abs' success can also be attributed to their ongoing efforts to stay ahead of the curve when it comes to fitness trends and advancements. The company consistently conducts research and development to refine and enhance their products, ensuring that they remain at the forefront of innovation. Their team of experts is constantly exploring new techniques and technologies to create the most effective and efficient abdominal exercise machines on the market.In line with their commitment to innovation, Machined Abs is thrilled to announce the launch of its latest product – the Advanced Abdominal Trainer. This state-of-the-art machine is the result of years of research and development, and it is poised to revolutionize the way individuals approach abdominal workouts.The Advanced Abdominal Trainer is equipped with a wide range of features that set it apart from other machines on the market. It boasts an adjustable resistance system that allows users to customize their workouts according to their fitness level and goals. The machine's ergonomic design ensures that users maintain proper form throughout their workouts, minimizing the risk of strain or injury.Furthermore, the Advanced Abdominal Trainer incorporates cutting-edge technology to provide users with real-time feedback on their workouts. The built-in digital display tracks essential metrics such as reps, sets, and calories burned, empowering users to monitor their progress and make informed decisions about their fitness routines."We are thrilled to introduce the Advanced Abdominal Trainer to our lineup of fitness equipment," says the CEO of Machined Abs. "This machine represents the pinnacle of our efforts to create a product that delivers unparalleled results and enhances the overall fitness experience. We are confident that this machine will exceed the expectations of our customers and solidify our position as a leader in the industry."In conclusion, Machined Abs is a trailblazer in the fitness equipment industry, and their commitment to excellence and innovation has fueled their success. Their dedication to producing top-quality abdominal exercise machines and providing exceptional customer service has earned them a reputation as a trusted provider of fitness equipment. With the launch of the Advanced Abdominal Trainer, Machined Abs continues to raise the bar for what individuals can expect from their fitness equipment, providing them with the tools they need to achieve their fitness goals effectively.

Comparison: Machining 304 Stainless Steel vs 316 Stainless Steel

Title: A Comparative Analysis: Machining 304 Vs 316 Stainless SteelIntroduction:In the world of metal fabrication and manufacturing, stainless steel is one of the most widely used materials due to its exceptional corrosion resistance and durability. Two common stainless steel varieties are 304 and 316, both known for their unique properties and applications across various industries. In this article, we will delve into a comparative analysis of machining these stainless steel grades, exploring their characteristics, benefits, and potential applications.Machining 304 Stainless Steel:304 stainless steel, a versatile and widely-used material, offers excellent corrosion resistance, high-temperature resistance, and good formability. It is commonly found in food processing equipment, kitchen appliances, and architectural applications. Machining 304 stainless steel presents several advantages, making it a preferred choice in many manufacturing processes.1. Machinability: 304 stainless steel offers excellent machinability due to its lower carbon content compared to other stainless steel grades. This characteristic promotes efficient chip formation, resulting in improved tool life and reduced cycle times for machining processes.2. Cuttability: The relatively lower hardness of 304 stainless steel makes it easier to cut, reducing machine wear and tear. It can be quickly drilled, tapped, milled, and turned, enabling manufacturers to achieve precise and intricate designs effortlessly.3. Weldability: 304 stainless steel exhibits superior weldability, allowing for easy and efficient joining with a variety of techniques, including TIG and MIG welding. This facilitates the fabrication of complex structures and components without compromising the material's strength and integrity.4. Surface Finish: Machined 304 stainless steel can achieve a smooth and lustrous surface finish, making it ideal for applications where aesthetics play a crucial role, such as architectural elements or decorative pieces.Machining 316 Stainless Steel:316 stainless steel, often referred to as marine-grade stainless steel, is known for its outstanding resistance to corrosive environments, particularly chloride-containing solutions. Due to its superior corrosion resistance, it finds applications in marine equipment, chemical processing plants, and medical devices. While machining 316 stainless steel presents some challenges, it offers unique benefits that make it indispensable in specific industries.1. Hardness: Compared to 304 stainless steel, 316 stainless steel has a slightly higher hardness. While this makes machining more demanding, it also contributes to its enhanced strength, ideal for heavy-duty applications where mechanical strength is paramount.2. Heat Resistance: 316 stainless steel exhibits excellent high-temperature resistance, making it suitable for applications involving extreme heat, such as heat exchangers and furnace parts. The material's ability to withstand prolonged exposure to elevated temperatures adds to its versatility in various industrial settings.3. Corrosion Resistance: The corrosion resistance of 316 stainless steel surpasses that of 304 stainless steel, particularly in chloride-rich environments. This makes it the go-to choice for applications exposed to harsh or corrosive conditions, such as chemical processing plants or saltwater environments.4. Biocompatibility: 316 stainless steel is biocompatible, making it suitable for applications within the medical field. Its resistance to corrosion within the human body enables the fabrication of surgical instruments, implants, and other medical devices.Conclusion:Both 304 and 316 stainless steel offer unique properties beneficial for various applications in numerous industries. While 304 stainless steel provides excellent machinability and is commonly used in architectural and food processing applications, 316 stainless steel outperforms it in terms of corrosion resistance and high-temperature durability. Understanding the differences between these two stainless steel grades enables manufacturers to select the most suitable material for their specific requirements, ensuring optimal performance and longevity in their end products.

Top Tips for Small Aluminum Parts Machining: Everything You Need to Know

CNC Small Aluminum Parts are an essential component in the manufacturing industry. They are used in various applications including aerospace, automotive, electronics, and consumer goods. These precision parts are manufactured using computer numerical control (CNC) machines, which ensure high accuracy and repeatability in production.With the increasing demand for high-quality CNC small aluminum parts, a leading company in the industry has been making waves with its superior manufacturing capabilities and commitment to excellence. Specializing in the production of CNC small aluminum parts, the company {} has established itself as a trusted supplier to numerous industries.The company has a state-of-the-art manufacturing facility equipped with advanced CNC machines and tools. Using the latest technology and a team of highly skilled engineers and technicians, they are able to produce a wide range of small aluminum parts with intricate designs and tight tolerances. This allows the company to cater to the diverse needs of their clients and deliver top-quality parts that meet the highest industry standards.One of the key factors that set the company apart from its competitors is its ability to work with a variety of aluminum alloys. Aluminum is a lightweight and durable material that is ideal for a wide range of applications. By offering parts made from different aluminum alloys, the company is able to provide solutions that are tailored to the specific requirements of their customers.In addition to their manufacturing capabilities, the company also places a strong emphasis on quality control and inspection. Every CNC small aluminum part undergoes rigorous testing to ensure that it meets the desired specifications and performance standards. This commitment to quality and precision has earned the company a reputation for reliability and excellence in the industry.Furthermore, the company prides itself on its ability to offer customized solutions to its clients. With a team of experienced engineers and designers, they are able to work closely with customers to develop custom designs and prototypes. This collaborative approach allows the company to create unique parts that are tailored to the specific needs of each client, further solidifying their position as a trusted partner in the industry.As the demand for CNC small aluminum parts continues to grow, the company has also been focused on expanding its production capabilities and capacity. With ongoing investments in technology and infrastructure, they aim to meet the evolving needs of their customers and maintain their position as a leader in the industry.In conclusion, CNC small aluminum parts play a crucial role in various industries, and the company {} has proven to be a reliable and innovative supplier in this space. With its advanced manufacturing capabilities, commitment to quality, and emphasis on customization, the company is well-positioned to address the growing demand for precision small aluminum parts and continue to serve as a trusted partner for its customers.

Get Superior Custom Cut Gears for Precision Mechanical Applications

Custom Cut Gears Launches New Line of High-Quality Gears for Industrial Applications[City, State] – [Date] – Custom Cut Gears, a leading manufacturer of precision gears, announced today the launch of their latest line of high-quality gears designed for industrial applications. With their commitment to excellence and state-of-the-art manufacturing processes, Custom Cut Gears aims to provide top-notch solutions to meet the specific needs of various industries.With over 20 years of experience in the industry, Custom Cut Gears has built a reputation for delivering gears of the highest quality that meet or exceed customer requirements. Their team of skilled engineers and technicians specialize in producing gears with exceptional precision, durability, and performance. This new line of gears further solidifies their position as an industry leader.The newly launched line of gears caters to a wide range of industrial applications, including automotive, aerospace, robotics, marine, and more. Custom Cut Gears offers a diverse selection of gear types, such as spur gears, helical gears, bevel gears, worm gears, and planetary gears, among others. This extensive range ensures that customers can find the perfect gear solution for their specific application.What sets Custom Cut Gears apart is their commitment to customization. They understand that each industry has unique requirements, and thus offer customization options to tailor gears to the precise needs of their customers. From material selection to tooth profile modifications, customers can work with Custom Cut Gears to optimize the gears' performance for their specific applications. This level of flexibility ensures that customers receive gears that not only meet their requirements but also enhance their overall efficiency and productivity.Furthermore, all gears manufactured by Custom Cut Gears undergo rigorous quality control processes to ensure the highest level of accuracy and reliability. Their state-of-the-art facility is equipped with advanced machinery and inspection systems, enabling them to maintain tight tolerances and consistent quality across every gear produced. Custom Cut Gears adheres to strict industry standards and certifications, demonstrating their commitment to delivering products of the utmost integrity."We are thrilled to introduce our new line of high-quality gears for industrial applications," said [Spokesperson's Name], spokesperson for Custom Cut Gears. "Our team has put in tremendous effort to develop gears that not only meet industry standards but also exceed customer expectations. With our focus on customization, we aim to provide gears that empower our customers to achieve optimal performance in their respective applications."Custom Cut Gears has collaborated with numerous customers across various industries and successfully helped them solve complex gear-related challenges. Their team of experts works closely with clients to understand their unique requirements and develop gear solutions that deliver exceptional results. The combination of expertise, customization options, and dedication to quality makes them the preferred choice for many companies worldwide.As Custom Cut Gears continues to grow, they remain committed to investing in research and development to stay ahead of industry trends. They are constantly exploring new technologies and techniques to improve their manufacturing processes and design capabilities. This commitment ensures that their customers receive innovative and reliable gear solutions that align with the rapidly evolving industrial landscape.About Custom Cut Gears: Custom Cut Gears is a leading manufacturer of precision gears, specializing in the production of high-quality gears for various industrial applications. With over 20 years of experience, their skilled team of engineers and technicians deliver customized gear solutions that meet the specific needs of their diverse clientele. Custom Cut Gears' commitment to excellence, customization, and quality sets them apart as a trusted gear manufacturer in the industry.For more information about Custom Cut Gears and their range of products, please visit [website] or contact [contact information].

High-Quality Small Turned Parts for Precision Engineering Projects

Small Turned Parts, a leading manufacturer in the precision engineering industry, has recently announced the launch of their latest range of high-quality turned parts. With over 20 years of experience in the industry, Small Turned Parts has established itself as a trusted provider of precision engineered components for a wide range of industries, including automotive, aerospace, medical, and electronics.The company specializes in the production of custom turned parts, using state-of-the-art CNC machining technology to produce components with tight tolerances and complex geometries. Small Turned Parts prides itself on its ability to provide bespoke solutions to meet the specific needs of its clients, offering a comprehensive design and engineering service to ensure that each component meets the exact specifications required.The new range of turned parts includes a variety of components, such as precision shafts, connectors, bushings, and fittings. These components are manufactured using a range of high-quality materials, including stainless steel, brass, aluminum, and plastics, ensuring that Small Turned Parts can cater to the diverse needs of its customers.With a commitment to quality and precision, Small Turned Parts employs a rigorous quality control process to ensure that all components meet the highest standards. The company is ISO 9001 certified, demonstrating its dedication to maintaining consistently high levels of quality in its production processes. This commitment to quality has helped Small Turned Parts to build long-term relationships with its clients, who rely on the company to deliver reliable and durable components for their applications.Small Turned Parts is dedicated to investing in the latest technology and machinery to maintain its competitive edge in the industry. The company's production facility is equipped with advanced CNC machining centers, turning machines, and inspection equipment, allowing Small Turned Parts to produce components with the highest levels of precision and accuracy.In addition to its manufacturing capabilities, Small Turned Parts also offers a range of value-added services to its customers. These services include design and engineering support, rapid prototyping, and custom packaging solutions, ensuring that Small Turned Parts can provide a comprehensive service to its clients from concept to production.Small Turned Parts is committed to sustainability and environmental responsibility in its operations. The company has implemented a range of initiatives to minimize its environmental impact, including the use of energy-efficient machinery and the recycling of waste materials. Small Turned Parts also works closely with its suppliers to ensure that the materials used in its production processes are ethically sourced and environmentally friendly.As Small Turned Parts continues to grow and expand its capabilities, the company remains dedicated to its core values of quality, precision, and customer satisfaction. With its latest range of turned parts, Small Turned Parts aims to continue providing innovative solutions to meet the evolving needs of its clients across a wide range of industries.For more information about Small Turned Parts and its range of precision turned parts, visit their website {} or contact their sales team to discuss your requirements.

High-Quality Acrylic Machining Services: Precision and Efficiency for Your Projects

Title: Precision Acrylic Machining – Revolutionizing Manufacturing ProcessesIntroduction:In the bustling world of manufacturing, technological advancements play a crucial role in shaping the industry's landscape. One such innovation is Acrylic Machining, a cutting-edge manufacturing process that has gained immense popularity due to its precision and versatility. This article explores the transformative potential of Acrylic Machining in various industries, providing an overview of its capabilities and highlighting the leading company leading the charge.Background:Acrylic Machining is a technique utilized to reshape and fabricate acrylic materials with exceptional precision. Acrylics themselves are highly durable and lightweight, making them widely used in industries such as automotive, aerospace, electronics, and healthcare. The advent of Acrylic Machining brings forth a myriad of possibilities in manufacturing, allowing companies to produce intricate designs, complex components, and prototypes with unparalleled accuracy.Company Introduction:Recognizing the immense potential of Acrylic Machining, ABC Manufacturing has emerged as a pioneering force in this field. With years of experience, state-of-the-art facilities, and a team of skilled professionals, ABC Manufacturing has garnered a reputation for delivering high-quality acrylic machining services to clients worldwide. Their commitment to innovation and excellence has made them a trusted partner for businesses seeking precise, reliable, and cost-effective manufacturing solutions.The Capabilities of Acrylic Machining:1. Precision Cutting:Acrylic Machining employs advanced CNC (Computer Numerical Control) technology, enabling intricate and precise cutting methods. Through this process, complex shapes, patterns, and designs can be effortlessly achieved, surpassing the limitations of traditional manufacturing techniques.2. Versatility:Acrylics come in different forms, such as sheets, rods, and tubes. Acrylic Machining efficiently caters to these different forms, accommodating various manufacturing requirements with ease. From simple customized components to intricate designs, the possibilities are limitless.3. Enhanced Efficiency:With the advent of Acrylic Machining, production processes have become significantly more efficient. The advanced machining techniques minimize material waste and maximize productivity, ultimately reducing costs and saving valuable resources for businesses.4. Surface Finishing:Acrylic Machining not only focuses on precision cutting but also provides a range of surface finishing options. This includes polishing, beveling, engraving, and sandblasting, enabling businesses to enhance the aesthetic appeal and functionality of their acrylic products.Applications:1. Automotive Industry:Acrylic Machining revolutionizes the automotive industry by producing high-quality acrylic components. These include dashboards, light lenses, mirrors, and even windows. The precision and durability of these parts contribute to improved safety, fuel efficiency, and overall design aesthetics.2. Aerospace Industry:In the aerospace sector, Acrylic Machining enables the production of lightweight and durable acrylic components for aircraft cabins, windows, and transparent structures. By reducing weight and enhancing transparency, the technology plays a crucial role in increasing fuel efficiency and providing a better flying experience.3. Electronics Industry:Acrylic Machining finds extensive usage in the electronics industry due to its ability to manufacture intricate designs. Components like display screens, control panels, and LED light fixtures benefit from the technology's precision and versatility, leading to elegant and functional products.4. Healthcare Industry:The healthcare sector utilizes Acrylic Machining for manufacturing medical implants, surgical devices, protective barriers, and even laboratory equipment. The sterile and easy-to-clean nature of acrylic materials, combined with the precision provided by Acrylic Machining, make it highly appropriate for creating crucial medical apparatus.Conclusion:As modern manufacturing demands continue to evolve, the emergence of Acrylic Machining has proven to be a game-changer. Its precise cutting techniques, versatility, enhanced efficiency, and surface finishing options have revolutionized manufacturing processes across various industries. ABC Manufacturing, at the forefront of this revolution, stands ready to deliver top-notch acrylic machining solutions to businesses worldwide, ensuring the continued growth and development of the manufacturing landscape.

High-Quality Custom CNC Machining Services for Precision Parts

Custom CNC Machining Services Offered by Leading Manufacturing CompanyIn the ever-evolving world of manufacturing, precision and efficiency are key. This is where custom CNC machining comes into play, providing companies with the capability to produce highly detailed and accurate parts for a wide range of industries. One leading manufacturing company, {Company Name}, is at the forefront of this technology, offering a comprehensive range of custom CNC machining services to meet the diverse needs of its clients.Established in {year}, {Company Name} has built a strong reputation as a top-tier manufacturing company, specializing in custom CNC machining, CNC turning, and CNC milling. With state-of-the-art facilities and a team of skilled professionals, the company is able to deliver high-quality parts and components to clients across various industries, including aerospace, automotive, medical, and more.One of the key aspects of {Company Name}'s custom CNC machining services is its ability to work with a wide range of materials. From aluminum and stainless steel to exotic alloys and plastics, the company has the expertise and machinery to handle even the most challenging materials with precision and accuracy. This capability allows {Company Name} to cater to the unique needs of each client, offering custom solutions that meet their specific material requirements.Furthermore, {Company Name} understands that time is of the essence in manufacturing, which is why it has invested heavily in cutting-edge CNC machines and software to optimize its production processes. This not only ensures fast turnaround times but also guarantees the highest level of quality and consistency in every part produced. By leveraging advanced CNC technology, the company is able to deliver precision parts with tight tolerances, intricate geometries, and complex features, meeting the exact specifications of its clients.{Company Name} prides itself on its ability to provide personalized and customer-centric services. From the initial consultation to the delivery of the finished parts, the company works closely with its clients to understand their unique requirements and provide tailored solutions that exceed their expectations. Whether it's a low-volume prototype or a high-volume production run, {Company Name} is committed to delivering the highest level of service and quality, ensuring customer satisfaction every step of the way.In addition to its expertise in custom CNC machining, {Company Name} also offers value-added services such as assembly, finishing, and quality inspections to provide its clients with a complete manufacturing solution. This comprehensive approach allows the company to streamline the production process and deliver fully finished parts, ready for immediate integration into the final product.As the manufacturing industry continues to evolve, {Company Name} remains at the forefront of innovation, constantly pushing the boundaries of custom CNC machining to meet the evolving needs of its clients. By combining advanced technology, skilled craftsmanship, and personalized service, the company has established itself as a trusted partner for companies looking to bring their innovative designs to life.In conclusion, {Company Name} is a leading manufacturing company that offers a comprehensive range of custom CNC machining services, catering to the diverse needs of its clients in various industries. With its state-of-the-art facilities, advanced CNC technology, and commitment to customer satisfaction, {Company Name} is well-equipped to deliver high-quality, precision parts that meet the exact specifications of its clients. As the manufacturing landscape continues to evolve, {Company Name} remains dedicated to pushing the boundaries of custom CNC machining and delivering innovative solutions to its clients.